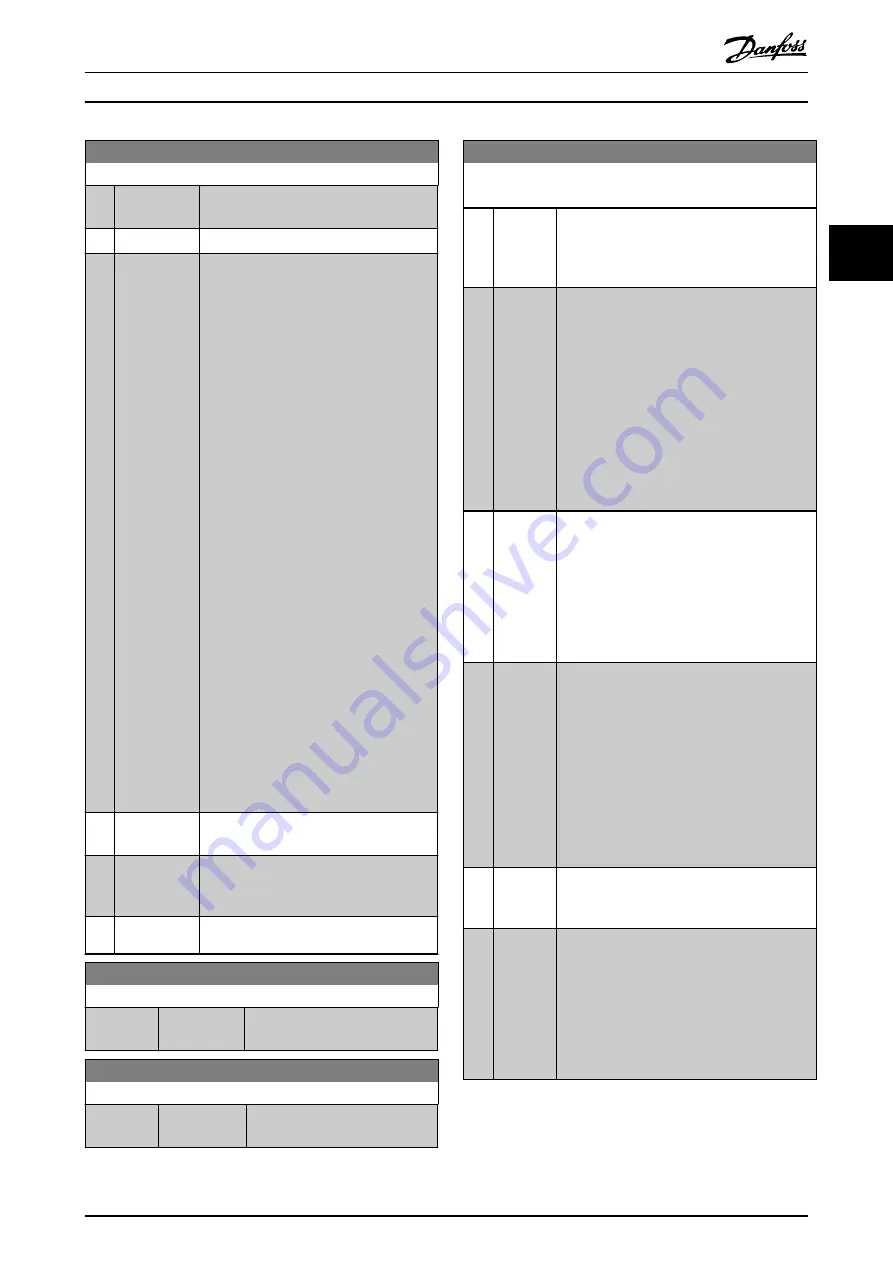

1-80 Function at Stop

Option:

Function:

[1]

DC hold

Energizes motor with a DC holding current

(see

).

[2]

Motor check

Checks if a motor has been connected.

[3]

Pre-

magnetizing

Builds up a magnetic field while the motor

is stopped. This allows the motor to

produce torque quickly at subsequent start

commands (asynchronous motors only). This

Pre-magnetizing function does not help the

very first start command. Two different

solutions are available to pre-magnetize the

machine for the first start command:

1. Start the frequency converter

with a 0 RPM reference and wait 2

to 4 rotor time constants (see

below) before increasing the

speed reference.

2a. Set

to the

desired pre-mag time (2 to 4 rotor

time constants - see below).

2b. Set

to

either

[0] DC-hold

or

[1] DC-Brake

.

Set the DC-hold or DC-brake

current magnitude (

or

)

to be equal to I_pre-mag = Unom/

(1.73 x Xh)

Sample rotor time constants =

(Xh+X2)/(6.3*Freq_nom*Rr)

1 kW = 0.2 seconds

10 kW = 0.5 seconds

100 kW = 1.7 seconds

1000 kW = 2.5 seconds

[4]

DC Voltage

U0

When the motor is stopped, the P1-55 [0]

parameter defines the voltage at 0Hz.

[5]

Coast at low

reference

When the reference is below

1-81 Min Speed

for Function at Stop [RPM]

, the motor is

disconnected from the frequency converter.

[6]

Motor check,

alarm

1-81 Min Speed for Function at Stop [RPM]

Range:

Function:

Size related

*

[0 - 600 RPM] Set the speed at which to activate

1-80 Function at Stop

.

1-82 Min Speed for Function at Stop [Hz]

Range:

Function:

Size related

*

[0.0 - 20.0 Hz] Set the output frequency at which

to activate

1-80 Function at Stop

.

1-83 Precise Stop Function

FC 302 only.

Option:

Function:

[0]

*

Precise

ramp stop

Only optimal when the operational speed - of

e.g. the conveyor belt - is constant. This is an

open loop control. Achieves high repetitive

precision at the stopping point.

[1]

Cnt stop

with reset

Counts the number of pulses, typically from an

encoder and generates a stop signal after a pre-

programmed number of pulses -

- has been received at T29

or T33 [30].

This is a direct feedback with one-way closed

loop control.

The counter function is activated (starts timing)

at the edge of the start signal (when it changes

from stop to start). After each precise stop the

number of pulses counted during ramp down

to 0 rpm is reset.

[2]

Cnt stop

w/o reset

Same as [1] but the number of pulses counted

during ramp down to 0 rpm is deducted from

the counter value entered in

.

This reset function can for example be used to

compensate for the extra distance done during

ramping down and to reduce the impacts of

gradual wear of mechanical parts.

[3]

Speed

comp

stop

Stops at precisely the same point, regardless of

the present speed, the stop signal is delayed

internally when the present speed is lower than

the maximum speed (set in

).

The delay is calculated on the basis of the

reference speed of the frequency converter and

not on the basis of the actual speed. Please

therefore make sure that the frequency

converter has ramped up before you activate

the speed compensated stop.

[4]

Com cnt

stop w/rst

Same as [3] but after each precise stop the

number of pulses counted during ramp down

to 0 rpm is reset.

[5]

Comp cnt

stop w/o

r

Same as [3] but the number of pulses counted

during ramp down to 0 rpm is deducted from

the counter value entered in

.

This reset function can for example be used to

compensate for the extra distance done during

ramping down and to reduce the impacts of

gradual wear of mechanical parts.

The Precise Stop Functions are advantageous in

applications where high precision is required.

If you use a standard stop command the accuracy is

determined by the internal task time. That is not the case

Parameter Descriptions

VLT

®

AutomationDrive Programmming Guide

MG33ME02 - VLT

®

is a registered Danfoss trademark

45

3

3