63

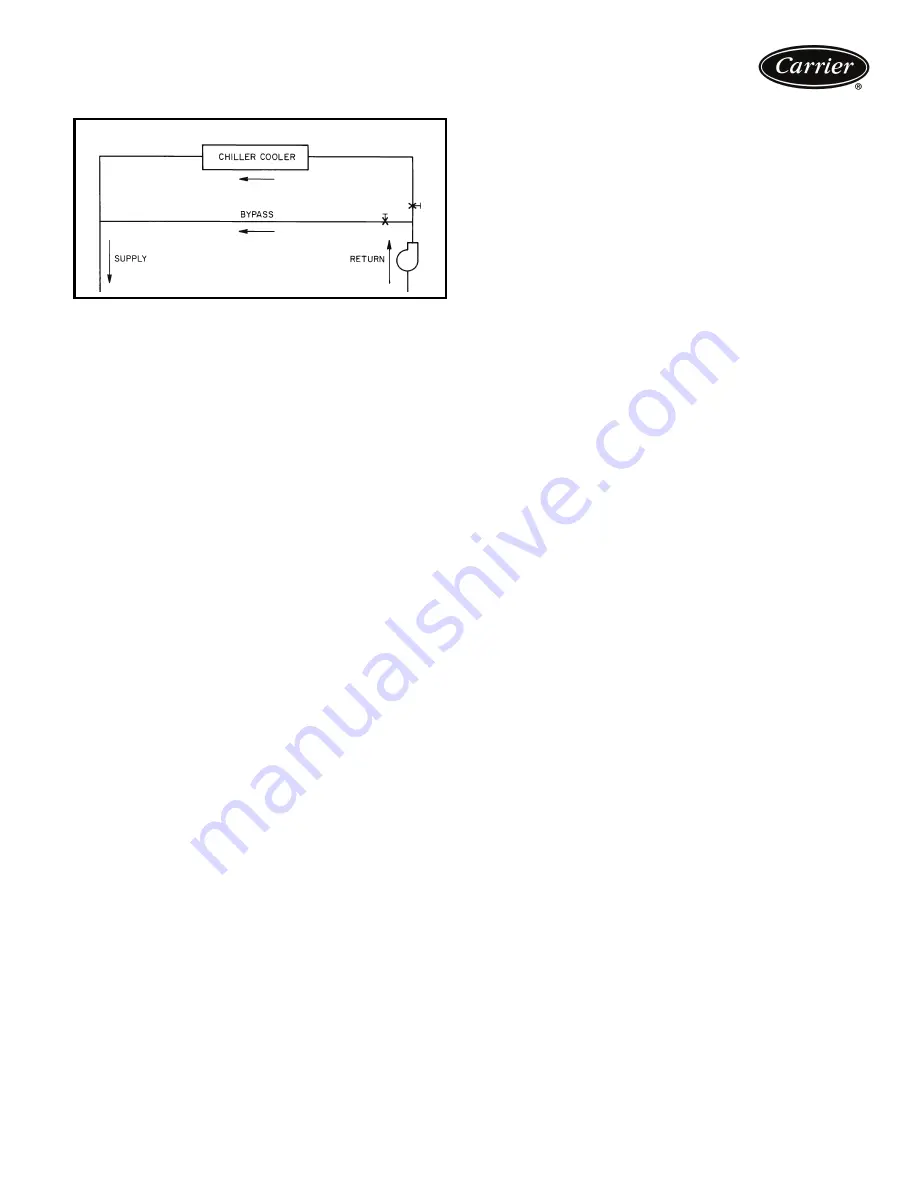

NOTE: Bypass flow is shown below.

Variable cooler flow rates

Variable flow rates may be applied to a standard chiller.

The unit will, however, attempt to maintain a constant

leaving chilled water temperature. In such cases, minimum

flow must be in excess of minimum flow given in the Mini-

mum and Maximum Cooler Fluid Flow Rates table on page

65, and minimum fluid volume in circulation must be in

excess of those values shown for normal air-conditioning

applications in the Minimum Fluid Volume in Circulation

table. Flow rate must change in steps of less than 10% per

minute. Apply 6 gal. or more per ton (6.5 L per kW) water

loop volume minimum if flow rate changes more rapidly.

The 30RAP chiller is available without a hydronic pump-

ing package, a constant-speed pumping package, or with a

variable-speed drive pumping package on sizes 070-090.

Traditional pumping systems incorporate constant speed

drives and waste energy by relying upon throttling valves as

the only means to control flow. A more energy-efficient

approach to this issue is use a variable-speed drive. The

30RAP070-090 units are now available with an optional

variable-speed hydronic package with sensorless technol-

ogy to meet this market requirement.

The major cost of a pump over its lifetime will be energy

consumption and maintenance, and both of these factors

will be reduced using variable-speed pumping. Energy is

saved by the combination of lowering the pump speed in

conjunction with the resulting lowering of pumping system

resistance when conditions permit. Maintenance benefits

from the sensorless pumping system include the lack of the

need to maintain remote sensors as well as the beneficial

effects of lower speed/pressure on the pump and pump

bearings.

Another advantage associated with variable-speed

pumping is reduced system noise in part-load operation

when the pump is running at lower speeds. The variable-

speed pump package offered on the 30RAP is offered

both in single and dual-pump designs. In the dual pump

case, in which one pump is the back-up of the other, each

pump connection is fitted with an isolation valve which

allows one pump to be isolated for service with the other

pump still operating.

As already mentioned, the 30RAP variable-speed

hydronic package employs sensorless technology. The

term "sensorless" means that no remote sensors are

required for pump operation. The sensorless pump

control monitors system requirements for pump speed and

power. The hydronic unit is provided with a pre-defined

control curve to automatically adjust speed at all operating

conditions. Pump performance and characteristic curves

for multiple speeds are programmed into the speed-con-

troller memory. The pre-programmed information includes

power, pressure and flow throughout the entire range of

the pump. During chiller operation, the power and speed

of the pump are monitored. This enables the controller to

establish the hydraulic performance, and to position the

pump's head-flow characteristic. Although this curve is pre-

defined, it is also fully field adjustable. The pump has a

graphical user interface, and the graphic keypad can also

be used to allow manual pump speed control.

This variable-speed pumping system easily connects to

BMS (Building Management System) systems (BACnet is

standard, and LON can be obtained via special order). The

pumps may be controlled directly by the BMS system. The

sensorless feature can also be switched off to allow the use

of either a 0 to 10 VDC signal or a 0 to 20 mA signal.

For multiple chiller applications employing the variable-

speed pumping package, such as chillers operated in a par-

allel arrangement, the drives must be connected by control

wiring and set up to run the same speed. This is to prevent

surging or hunting of the speed setpoint. One drive will act

as the master while the other slave drive will run at the

same speed. The master drive may be controlled by a 0 to

10 VDC signal, a 0 to 20 mA signal, or a BMS. The drive

must be configured to not use the sensorless function in

this arrangement.

A typical example of a chiller operating with a variable-

speed pumping system would be the case when the user

requires the chiller to operate with a constant fluid temper-

ature difference as the load is reduced. This can be accom-

plished with the 30RAP variable-speed pumping package

with the understanding that the minimum allowable flow

for the chiller must be respected. Once that limit is

reached, the flow cannot be further reduced. To accom-

plish this purpose, the minimum speed of the drive is pre-

set based upon the chiller size that is being employed.

As a specific example, let us say the schedule calls for a

90-ton, fresh-water chiller, and it is desired to have a con-

stant 10-degree temperature difference in part load opera-

tion (say 54 to 44 F). The schedule calls for 216 gpm at

full load based upon the desired capacity and the fluid tem-

perature difference. A constant temperature difference in

part load operation is essentially the same as providing

flow in direct proportion to chiller load. In the present

example, this means that 100% load will run at the sched-

uled 216 gpm, 90% load will be 194 gpm, etc. down to

the minimum allowable flow for this unit size, which, in the

case of a 30RAP090 unit, is 107 gpm. The chiller in this

example will therefore be able to run down to just under

50% load while approximately maintaining a constant 10

degree fluid temperature difference, and then the flow will

be held constant for all lower loads. Throughout the range

in which flow is reduced (down to minimum allowable

flow), the pump speed is proportionally reduced, resulting

in pump energy savings.

Fluid loop volume

The minimum volume of fluid required to be in circulation

is a function of the number of compressors in the chiller,

BYPASS FLOW

a30-533

Summary of Contents for Aquasnap 30RAP010

Page 14: ...14 a30 5349 Base unit dimensions 30RAP070 090...

Page 15: ...15 ACCESSORY STORAGE TANK FOR UNIT SIZES 010 015 a30 4879 Accessory dimensions...

Page 16: ...16 ACCESSORY STORAGE TANK FOR UNIT SIZES 018 030 a30 4880 Accessory dimensions cont...

Page 17: ...17 ACCESSORY STORAGE TANK FOR UNIT SIZES 035 060 a30 4881...

Page 60: ...60 600 760 a30 5264 Typical control wiring schematic...

Page 75: ......