Chapter 5

5-22

amount for the specified value.

Pressing SW383 [1] moves the staple position upward while pressing

SW384 [2] moves the staple position downward.

Adjustment range: +10 to -10 (correction amount per unit: 0.125mm)

After the adjustment value is specified, go through the following

procedure.

- No paper -> the adjustment value is overwritten and the mode

terminates.

- Paper present -> re-check the staple position and go back to step 8).

F-5-99

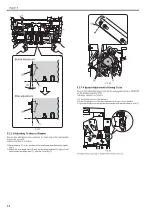

5.3.2.13 Adjusting Saddle Folding Position

0021-1720

Execute this adjustment in the case of displacement in folding position (sad-

dle delivery) or replacing EEPROM on the finisher controller PCB.

Adjusting method is as follows:

1) Turn ON the power of the finisher.

2) Turn ON the power switch of the host machine to be on standby.

3) Specify the booklet with 2 sheets or more (any) on the control panel and

make a copy.

4) Spread the bound paper to measure the folding position [2] against the sta-

ple position [1].

Adjustment is complete if the measured value is within the specification

(C = 0.5mm or less), otherwise execute the following work.

F-5-100

5) Open the front door and put the door switch tool into the door switch [1].

F-5-101

6) Remove the screw [2] to remove the switch cover [1].

F-5-102

7) Set DIP SW382 [1] on the switch PCB as shown in the figure below.

Then, press SW385 once so that the adjustment is ready now.

F-5-103

8) Work with the 2 push switches (SW383, 384) by calculating correction

value from the measured value.

Pressing SW383 [1] moves the folding position [2] upward while

pressing SW384 [2] moves the folding position [2] downward.

Adjustment range: +16 to -16 (correction amount per unit: 0.125mm)

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[1]

[2]

[1]

[2]

[C]

[1]

[2]

[1]

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[1]

Summary of Contents for Saddle Finisher-AF2

Page 1: ...SERVICE MANUAL Saddle Finisher AF2 MARCH 6 2009...

Page 2: ......

Page 6: ......

Page 12: ...Contents...

Page 13: ...Chapter 1 Specifications...

Page 14: ......

Page 16: ......

Page 22: ......

Page 23: ...Chapter 2 Installation...

Page 24: ......

Page 26: ......

Page 55: ...Chapter 3 Functions...

Page 56: ......

Page 58: ......

Page 104: ...Chapter 3 3 46...

Page 105: ...Chapter 4 Parts Replacement Procedure...

Page 106: ......

Page 110: ......

Page 157: ...Chapter 4 4 47 F 4 213 3 2 1...

Page 158: ......

Page 159: ...Chapter 5 Maintenance...

Page 160: ......

Page 209: ...Chapter 5 5 47 F 5 221 SW382 SW381 SW383 ENTER SW384 SW385 DSP381 1...

Page 218: ......

Page 219: ...Appendix...

Page 220: ......

Page 221: ...General Timing Chart General Circuit Diagram Finisher Sorter DeliveryTray Saddle Finisher AF2...

Page 222: ......

Page 224: ......

Page 225: ...Contents 1 General Circuit Diagram 1 Signal Names 1 General Circuit Diagram 9...

Page 226: ......

Page 243: ......

Page 244: ......