Chapter 5

5-5

F-5-15

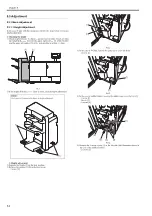

2) Lift the upper cover [1] in the arrow direction to remove the inner cover

(upper) [2].

- 4 screws [3]

F-5-16

3) Loosen the 2 screws [2] on the latch base (front) [1].

4) If the value obtained at "checking adjustment value" is "+ (positive)",

move it in [A] direction and tighten the screws [2].

If the value obtained at "checking adjustment value" is "- (negative)",

move it in [B] direction and tighten the screws [2].

F-5-17

5) Loosen the 2 screws [2] on the latch base (rear) [1].

6) If the value obtained at "checking adjustment value" is "+ (positive)",

move it in [A] direction and tighten the screws [2].

If the value obtained at "checking adjustment value" is "- (negative)",

move it in [B] direction and tighten the screws [2].

F-5-18

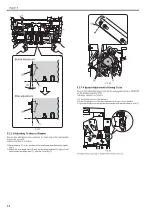

7) Connect the finisher with the host machine.

8) Turn ON the power switch of the host machine then the finisher.

9) Check the adjustment value again.

If the adjustment value indicated on the LED is within the range, press

ENTER button to complete the adjustment mode.

If the adjustment value indicated on the LED is out of the range, execute

adjustment for the second time. Adjustment can be considered OK to

complete if the value gets closer to the adjustment range (estimated

value).

10) Put the DIP switch setting back and install the removed covers/parts.

5.3.1.3 Adjusting Sensor Light Intensity

0021-1704

Execute this adjustment in the case of the following:

- When installing the finisher

- When replacing a sensor

- When replacing EEPROM (IC107) on the finisher controller PCB

Following shows the operating procedure:

CAUTION:

Be careful not to drop the bearing [1] that is attached inside the knob.

[2]

[1]

[1]

[2]

[3]

[1]

CAUTION:

Perform adjustment so that the total of the shifting amount (scale) of the

latch base (front/rear) is within -2 to +2 mm.

CAUTION:

Perform adjustment so that the total of the shifting amount (scale) of the

latch base (front/rear) is within -2 to +2 mm.

[B]

[A]

[1]

[2]

[B]

[A]

[1]

[2]

Summary of Contents for Saddle Finisher-AF2

Page 1: ...SERVICE MANUAL Saddle Finisher AF2 MARCH 6 2009...

Page 2: ......

Page 6: ......

Page 12: ...Contents...

Page 13: ...Chapter 1 Specifications...

Page 14: ......

Page 16: ......

Page 22: ......

Page 23: ...Chapter 2 Installation...

Page 24: ......

Page 26: ......

Page 55: ...Chapter 3 Functions...

Page 56: ......

Page 58: ......

Page 104: ...Chapter 3 3 46...

Page 105: ...Chapter 4 Parts Replacement Procedure...

Page 106: ......

Page 110: ......

Page 157: ...Chapter 4 4 47 F 4 213 3 2 1...

Page 158: ......

Page 159: ...Chapter 5 Maintenance...

Page 160: ......

Page 209: ...Chapter 5 5 47 F 5 221 SW382 SW381 SW383 ENTER SW384 SW385 DSP381 1...

Page 218: ......

Page 219: ...Appendix...

Page 220: ......

Page 221: ...General Timing Chart General Circuit Diagram Finisher Sorter DeliveryTray Saddle Finisher AF2...

Page 222: ......

Page 224: ......

Page 225: ...Contents 1 General Circuit Diagram 1 Signal Names 1 General Circuit Diagram 9...

Page 226: ......

Page 243: ......

Page 244: ......