5

5

5-5

5-5

Adjustment > Adjustment when Replacing the Parts > Laser Exposure System > After Replacing the Laser Scanner Unit

Adjustment > Adjustment when Replacing the Parts > Laser Exposure System > After Replacing the Laser Scanner Unit

■

Before Replacing the DC Controller PCB

1) Request the user to backup the user data using remote UI.

2) If possible, output the data of the unprocessed jobs.

After replacing the DC Controller PCB, the data of the unprocessed jobs will be deleted.

3) Print out the list of the service mode setting value in the service mode.

REPORT> REPORT OUTPUT> SERVICE DATA LIST

■

After Replacing the DC Controller PCB

1) When replacing the DC Controller PCB with a new one, be sure to perform the following

procedure.

• Download the latest firmware using UST.

(Refer to Software to Be Upgraded and Upgrading Method)

2) Clear the DC Controller setting value/counter.

Service mode > CLEAR > ENGINE > ENGINE BKRAMCLK

(Clearing RAM of the DC Controller PCB)

3) Turn OFF and then ON the power.

(By turning OFF and then ON the power, RAM clear is executed.)

4) When backup data cannot be uploaded before replacement due to reasons such as

damage of the DC Controller PCB, enter the value of each #PRINT item described on the

service label.

Since the values recorded on the service label may not be the latest at this time, check the

service mode item list (#SERVICE DATA LIST) printed out in advance, and enter the values

on the list.

5) Turn OFF and then ON the main power.

(By turning OFF and then ON the power, the value entered in each service mode item

becomes enabled.)

6) Upon completion of the replacement work, request the user to restore the user data.

■

When Replacing the RAM PCB

CAUTION:

Even after turning OFF the main power switch and disconnecting the power plug from

the outlet, power is still supplied between SO-DIMM and Secondary Battery Unit for

backup of the image memory. When the SW3 of the Main Controller PCB is pressed

while image is backed up, all the contents in the memory are cleared, therefore be sure

to output all data in the memory before pressing it.

Laser Exposure System

■

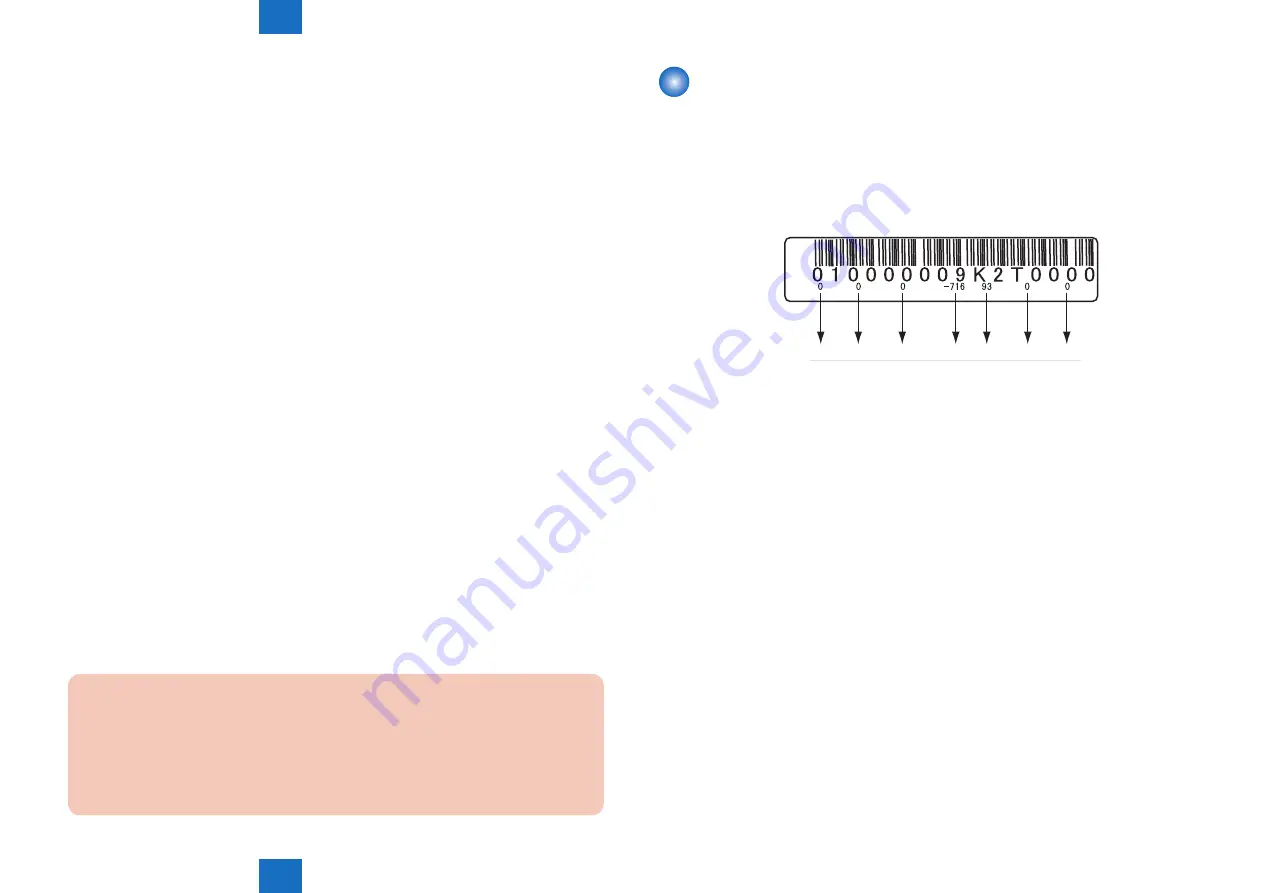

After Replacing the Laser Scanner Unit

When replacing the Laser Unit, enter the value obtained by adding 1,000 to the number

shown on the label affixed to the side of the newly replaced Laser Unit in the corresponding

service mode as shown below.

(Examples: If the number on the service label is 3, enter 1,003. If the number on the service

label is -1, enter 999.)

145

146

147

136 148

149

150

SW No.

PRINT > PRINT NUMERIC >

136 Laser horizontal scanning direction write position adjustment (A)

PRINT > PRINT NUMERIC >

145 Laser horizontal scanning direction magnification ratio adjustment (A-B)

PRINT > PRINT NUMERIC >

146 Laser horizontal scanning direction magnification ratio adjustment (A-C)

PRINT > PRINT NUMERIC >

147 Laser horizontal scanning direction magnification ratio adjustment (A-D)

PRINT > PRINT NUMERIC >

148 Laser horizontal scanning direction write position adjustment (A-B)

PRINT > PRINT NUMERIC >

149 Laser horizontal scanning direction write position adjustment (A-C)

PRINT > PRINT NUMERIC >

150 Laser horizontal scanning direction write position adjustment (A-D)

F-5-5

Summary of Contents for 1730

Page 12: ...Update Firmware XXV Volume Control XXV Backup Data XXVI ...

Page 17: ...1 1 Product Overview Product Overview Product Lineup Features Specifications Parts Name ...

Page 235: ...7 7 Error Code Error Code Overview Error Code Jam Code Alarm Code ...

Page 250: ...8 8 Service Mode Service Mode Outline Details of Service Mode ...

Page 333: ... Service Tools General Timing Chart General Circuit Diagram List of User Mode Appendix ...