2-18

2002 Buell P3: Chassis

HOME

INSTALLATION

1

1

WARNING

1

WARNING

Only install original equipment (stock) tire valves and

valve caps. A valve or valve and cap combination that is

too long may interfere with (strike) adjacent components,

damage the valve and cause rapid tire deflation. Rapid

tire deflation could cause loss of control which could

result in death or serious injury.

1

1

WARNING

1

WARNING

Aftermarket valve caps that are heavier than the stock

cap may have clearance at slow speeds; but, at high

speed the valve/cap will be moved outward by centrifugal

force. This outward movement could cause the valve/cap

to strike the adjacent components, damage the valve and

cause rapid tire deflation. Rapid tire deflation could

cause loss of control which could result in death or seri-

ous injury.

1.

Damaged or leaking valve stems must be replaced.

Place rubber grommet on valve stem with shoulder in

recess of the valve stem head.

2.

Install and tighten nut to 42-44

in-lbs

(4.7-5.0 Nm).

3.

Thoroughly lubricate rim flanges and both beads of tire

with tire lubricant.

4.

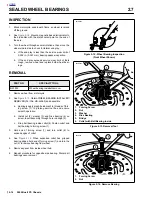

See

Figure 2-22.

Starting at the valve stem, start first

bead into the rim well using a bead breaker machine. If

no machine is available, work bead on as far as possible

by hand. Use a tire tool to pry the remaining bead over

rim flange.

5.

Start 180° from valve stem hole and place second bead

on rim. Work bead onto rim with tire tools, working

toward valve in both directions.

1

1

WARNING

1

WARNING

Do not inflate over 40 psi (276 kPa) to seat the beads.

Inflating the tire beyond 40 psi (276 kPa) to seat the

beads can cause the tire rim assembly to burst with force

which could result in death or serious injury.

6.

Apply air to stem to seat beads on rim. It may be neces-

sary to use a TIRE BEAD EXPANDER (Part No. HD-

28700) on the tire until beads seal on rim.

Checking Tire Lateral Runout

1.

See

Figure 2-23.

Turn wheel on axle and measure

amount of displacement from a fixed point to tire side-

wall.

2.

Tire tread lateral runout should be no more than 0.080

in. (2.03 mm). If runout is more than 0.080 in. (2.03 mm),

remove tire from rim.

3.

Check rim bead side runout. See

2.8 CHECKING CAST

RIM RUNOUT

. Replace rims not meeting specifications.

4.

Install tire and check again for tire tread lateral runout.

Checking Tire Radial Runout

1.

See

Figure 2-24.

Turn wheel on axle and measure tread

radial runout.

2.

Tire tread radial runout should not be greater than 0.060

in. (1.52 mm). If runout exceeds specification, remove

tire from rim.

3.

Check rim bead runout. See

2.8 CHECKING CAST RIM

RUNOUT

. Replace rims not meeting specifications.

4.

Install tire and check tire tread radial runout again.

Figure 2-22. Starting Bead on Rim (Typical)

Figure 2-23. Checking Tire Lateral Runout

Figure 2-24. Checking Tire Radial Runout

Lubricate rim flange and both

beads before installation

a0209x2x

Tire lateral

runout 0.080 in.

(2.03 mm)

maximum

Gauge

a0210x2x

a0211x2x

Tire radial

runout 0.060 in.

(1.52 mm)

maximum

Gauge

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...