3-48

2002 Buell P3: Engine

HOME

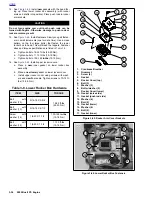

OILING SYSTEM

3.12

GENERAL

1.

Oil is gravity-fed from the oil reservoir to the gerotor-style

oil pump through a

feed hose.

Oil enters the

feed sec-

tion

and fills a cavity located under the feed pump.

NOTE

See

3.13 OIL PUMP

for a complete explanation of the gerotor

pump sets.

2.

The feed pump transfers oil from the inlet cavity through

the

external steel line

to the oil filter mount.

3.

Oil flows through the

filter mount cavity

to the oil filter.

4.

Oil enters the peripheral cavity of the

oil filter,

passes

through the filtering medium into the central cavity of the

oil filter, and flows into the filter adapter (fitting which

connects filter to filter mount).

5.

Adequate oil pressure in the filter mount cavity activates

the

oil pressure signal light switch

and shuts off the oil

pressure signal light.

6.

Oil flowing from the filter adapter opens the

check ball.

The check ball opens at 4-6 psi (28-41 kPa) oil pressure.

7.

With the check ball open, oil flows into the

crankcase

feed galley.

8.

Oil flows through the feed galley in the crankcase to the

tappet blocks and hydraulic lifters.

Cross-drilled pas-

sages

intersect the main feed galley and carry oil to both

hydraulic lifters.

9.

Oil also enters an

intersecting passage

in the gearcase

cover. Oil flow is then routed to the crankshaft area.

10. Oil enters a hole in the end of the

pinion gear shaft

and

travels to the right flywheel where it is routed through the

flywheel to the

crankpin.

Oil is forced through the crank-

pin to properly lubricate the rod bearing assembly.

11. Oil flows up passages in the

push rods

to the rocker

arm shafts and bushings.

12. The valve stems are lubricated by oil supplied through

drilled oil holes in the

rocker arms.

13. Oil collected in the push rod areas of the cylinder heads

flows down the

push rod cover,

through drain holes in

the

tappet blocks

and into the gearcase. After providing

lubrication to the gearcase components, the oil flows to

the left side of the oil pump.

14. Feed oil to the rocker area is returned to the crankcase

through a

passage

in the head and cylinder.

15. Oil collected in the

sump

is splash-fed to the pistons,

cylinder walls and flywheel components.

16. A single piston oil jet cools the bottom of the piston with

a spray of oil.

17. Oil collected in the sump area returns to the scavenge

section of the oil pump through a

passage

located in the

rear section of the sump. Oil flow to the pump is accom-

plished by the scavenging effect of the pump and by the

pressure created by the downward stroke of the pistons.

18. Return oil fills a

cavity

above the pump's return gears.

The return gears pump oil back to the oil reservoir.

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...