1-16

2002 Buell P3: Maintenance

HOME

CLUTCH

1.9

GENERAL

Check clutch for proper adjustment:

●

At the 1,000 mile (1,600 km) initial service and at

every 5,000 mile (8,000 km) service interval thereaf-

ter.

Oil and adjust the clutch control cable:

●

Every 5,000 miles (8,000 km) with LUBIT-8 TUFOIL

CHAIN AND CABLE LUBE (Part No. 94968-85TV).

ADJUSTMENT

Clutch control cable adjustment is required at this interval to

compensate for normal clutch lining wear. If the clutch slips

under load, or drags when released, adjust the clutch control

cable.

1.

Raise rear wheel off floor using REAR WHEEL SUP-

PORT STAND (Part No. B-41174).

2.

Remove left footpeg support bracket. See

2.21 FOOT-

PEGS AND FOOTPEG SUPPORT BRACKETS.

3.

See

Figure 1-11.

Slide rubber boot (1) upward to expose

adjuster mechanism. Loosen jam nut (3) from adjuster

(4). Turn adjuster to shorten cable housing until there is a

large amount of freeplay at clutch hand lever.

4.

See

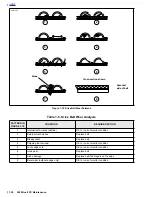

Figure 1-12.

Remove three TORX screws with

washers (1) from clutch inspection cover (2). Remove

clutch inspection cover from primary cover.

NOTE

Quad ring removed from primary cover for illustrative pur-

poses only in

Figure 1-12.

5.

Remove spring (4) and lockplate (5). Turn adjusting

screw (6) counterclockwise until it lightly bottoms.

6.

Turn adjusting screw (6) clockwise 1/4 turn. Install lock-

plate (5) and spring (4) on adjusting screw flats. If hex on

lockplate does not align with recess in outer ramp, rotate

adjusting screw clockwise until it aligns.

7.

Squeeze clutch hand lever to maximum limit three times.

This sets the ball and ramp mechanism. Pull outer cable

conduit and at the same time adjust cable adjuster to

provide 0.0625-0.125 in. (1.6-3.2 mm) freeplay at clutch

hand lever. Adjust as follows.

a. See

Figure 1-13.

Pull ferrule (end of cable housing)

away from bracket. Gap between ferrule and bracket

should be 0.0625-0.125 in. (1.6-3.2 mm).

b.

See

Figure 1-11.

Set freeplay by turning adjuster.

c.

Tighten jam nut against adjuster.

d.

Slide rubber boot over cable adjuster mechanism.

8.

Change or add transmission fluid if necessary.

NOTE

Clean parts before re-assembly and use a new gasket.

9.

See

Figure 1-12.

Install clutch inspection cover using

three TORX screws with washers. Tighten in a crosswise

pattern to 7-9 ft-lbs (9.5-12.2 Nm).

10. Check clutch cable freeplay. See Step 6 above.

11. Install left footpeg support bracket. See

2.21 FOOT-

PEGS AND FOOTPEG SUPPORT BRACKETS.

Figure 1-11. Clutch Cable Adjuster Mechanism

Figure 1-12. Clutch Release Mechanism

Figure 1-13. Adjusting Clutch Freeplay

a0159x6x

Rubber Boot

Cable End

Jam Nut

Adjuster

1.

TORX Screw

2.

Clutch Inspection Cover

3.

Quad Ring

4.

Spring

5.

Lockplate

6.

Adjusting Screw

a0155x6x

2

1

3

4

5

6

a0158x6x

Ferrule

Bracket

0.0625-0.125 in.

(1.6-3.2 mm)

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...