WINDING/INSTALLING THE BOBBIN

GET

T

ING REA

D

Y

25

1

d

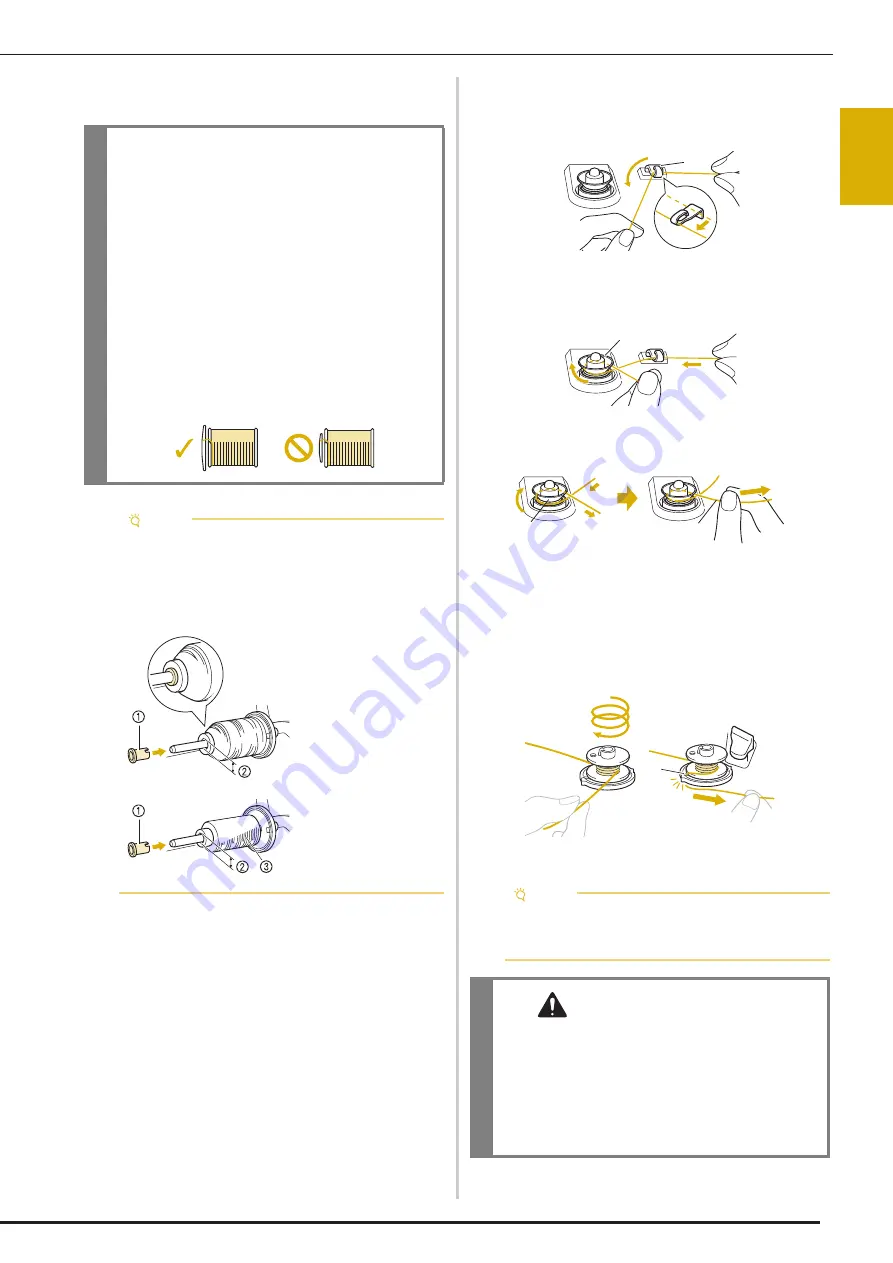

Slide the spool cap onto the spool pin as far as possible

to the right, with the rounded side on the left.

e

With your right hand, hold the thread near the thread

spool. With your left hand, hold the end of the thread,

and use both hands to pass the thread through the

thread guide.

1

Thread guide

f

Pass the thread around the pretension disk making sure

that the thread is under the pretension disk.

1

Pretension disk

Make sure that the thread passes under the

pretension disk.

2

Pretension disk

3

Pull it in as far as possible.

Check to make sure thread is securely set between

pretension disks.

g

Wind the thread clockwise around the bobbin 5 or 6

times, pass the thread through the guide slit in the

bobbin winder seat, and then pull the thread to cut it.

1

Guide slit in bobbin winder seat

(with built-in cutter)

IMPORTANT

• If the spool or the spool cap is not installed

correctly, the thread may become tangled

around the spool pin, and the machine may be

damaged.

• Three spool cap sizes are available, allowing

you to choose a spool cap that best fits the size

of spool being used. If the spool cap is too

small for the spool being used, the thread may

catch on the slit in the spool or the machine

may be damaged. When using mini king thread

spool, use the thread spool insert.

For details on thread spool insert (mini king

thread spool), refer to “Note” on page 25.

Note

• When using the spool as shown below, use the

thread spool insert (mini king thread spool). Make

sure that the thread spool insert is firmly inserted.

After installing it, pull out some thread, and check

that the thread unwinds without getting caught.

1

Thread spool insert

(mini king thread

spool)

2

Hole diameter 8.0

mm to 10.5 mm

(approx. 5/16 inch

to 13/32 inch)

3

Spool (cross-

wound thread)

Note

• Be sure to wind the thread clockwise around the

bobbin, otherwise the thread may become

wrapped around the bobbin winder shaft.

CAUTION

• Be sure to cut the thread as described. If the

bobbin is wound without cutting the thread

using the cutter built into the guide slit in the

bobbin winder seat, the thread may become

tangled in the bobbin or the needle may break

and cause injury when the bobbin thread starts

to run out.

a

a

b

c

a

Summary of Contents for Meridian 2

Page 1: ......

Page 2: ......

Page 10: ...CONTENTS 8...

Page 74: ...ADJUSTMENTS DURING THE EMBROIDERY PROCESS 72...

Page 112: ...IQ INTUITION POSITIONING APP 110...

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ...D02M4U 001 English 882 W84...