Frame Assembly

Page | 28

2)

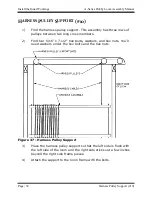

Figure

Note:

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

slip under the motor box, this will

bolts and blocks in place.

3)

4)

Frame Assembly

28

Make sure

and the round foot switch connector faces the front of the loom.

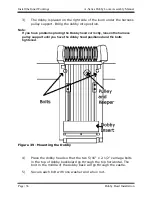

Figure 30 - E-lift attached to supports

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

slip under the motor box, this will

bolts and blocks in place.

From the top of the cross member, p

bolt and flat washer

with the exposed ends pointing to the floor.

Thread a mounting block onto each set of bolts and then engage

the bolts in the corresponding holes in the E

Make sure that the E

and the round foot switch connector faces the front of the loom.

lift attached to supports

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

slip under the motor box, this will

bolts and blocks in place.

From the top of the cross member, p

bolt and flat washer

with the exposed ends pointing to the floor.

Thread a mounting block onto each set of bolts and then engage

the bolts in the corresponding holes in the E

that the E-Lift power switch faces to the rear of the l

and the round foot switch connector faces the front of the loom.

lift attached to supports

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

slip under the motor box, this will help elevate it into position while getting the

bolts and blocks in place.

From the top of the cross member, p

bolt and flat washer into each of the four holes and let them hang

with the exposed ends pointing to the floor.

Thread a mounting block onto each set of bolts and then engage

the bolts in the corresponding holes in the E

A

Lift power switch faces to the rear of the l

and the round foot switch connector faces the front of the loom.

lift attached to supports

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

help elevate it into position while getting the

From the top of the cross member, p

into each of the four holes and let them hang

with the exposed ends pointing to the floor.

Thread a mounting block onto each set of bolts and then engage

the bolts in the corresponding holes in the E

A-Series Dobby Loom Assembly Manual

Lift power switch faces to the rear of the l

and the round foot switch connector faces the front of the loom.

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

help elevate it into position while getting the

From the top of the cross member, place one 5/16” x 6 1/2” hex

into each of the four holes and let them hang

with the exposed ends pointing to the floor.

Thread a mounting block onto each set of bolts and then engage

the bolts in the corresponding holes in the E-Lift mounting plate.

Series Dobby Loom Assembly Manual

Installation of the E

Lift power switch faces to the rear of the l

and the round foot switch connector faces the front of the loom.

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

help elevate it into position while getting the

lace one 5/16” x 6 1/2” hex

into each of the four holes and let them hang

Thread a mounting block onto each set of bolts and then engage

Lift mounting plate.

Series Dobby Loom Assembly Manual

allation of the E

Lift power switch faces to the rear of the loom

and the round foot switch connector faces the front of the loom.

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

help elevate it into position while getting the

lace one 5/16” x 6 1/2” hex

into each of the four holes and let them hang

Thread a mounting block onto each set of bolts and then engage

Lift mounting plate.

Series Dobby Loom Assembly Manual

allation of the E-Lift

oom

The motor box is quite heavy, so if you have a couple of pieces of 2” x 4” to

help elevate it into position while getting the

lace one 5/16” x 6 1/2” hex

into each of the four holes and let them hang

Thread a mounting block onto each set of bolts and then engage

Lift mounting plate.