301

2467S–AVR–07/09

ATmega128

Figure 144.

SPI Serial Programming and Verify

Notes:

1. If the device is clocked by the Internal Oscillator, it is no need to connect a clock source to the

XTAL1 pin.

2. V

CC

- 0.3V < AVCC < V

CC

+ 0.3V, however, AVCC should always be within 2.7 - 5.5V.

When programming the EEPROM, an auto-erase cycle is built into the self-timed programming

operation (in the serial mode ONLY) and there is no need to first execute the Chip Erase instruc-

tion. The Chip Erase operation turns the content of every memory location in both the Program

and EEPROM arrays into $FF.

Depending on CKSEL Fuses, a valid clock must be present. The minimum low and high periods

for the serial clock (SCK) input are defined as follows:

Low:> 2 CPU clock cycles for f

ck

< 12 MHz, 3 CPU clock cycles for f

ck

12 MHz

High:> 2 CPU clock cycles for f

ck

< 12 MHz, 3 CPU clock cycles for f

ck

12 MHz

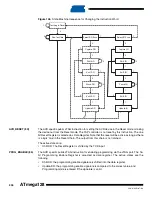

SPI Serial

Programming

Algorithm

When writing serial data to the ATmega128, data is clocked on the rising edge of SCK.

When reading data from the ATmega128, data is clocked on the falling edge of SCK. See

for timing details.

To program and verify the ATmega128 in the SPI Serial Programming mode, the following

sequence is recommended (See four byte instruction formats in

):

1.

Power-up sequence:

Apply power between V

CC

and GND while RESET and SCK are set to “0”. In some sys-

tems, the programmer can not guarantee that SCK is held low during power-up. In this

case, RESET must be given a positive pulse of at least two CPU clock cycles duration

after SCK has been set to “0”.

As an alternative to using the RESET signal, PEN can be held low during Power-on

Reset while SCK is set to “0”. In this case, only the PEN value at Power-on Reset is

important. If the programmer cannot guarantee that SCK is held low during power-up, the

PEN method cannot be used. The device must be powered down in order to commence

normal operation when using this method.

2.

Wait for at least 20 ms and enable SPI Serial Programming by sending the Programming

Enable serial instruction to pin MOSI.

VCC

GND

XTAL1

SCK

PDO

PDI

RESET

PE0

PE1

PB1

+2.7 - 5.5V

AVCC

+2.7 - 5.5V

(2)