ANDREWS COMBIfl o

22

GB

After cleaning and fl ushing of the system, it should be fi lled with an appropriate inhibitor or antifreeze treatment

to maintain water quality levels. The following system treatments have been tested and are recommended for

use with this appliance:

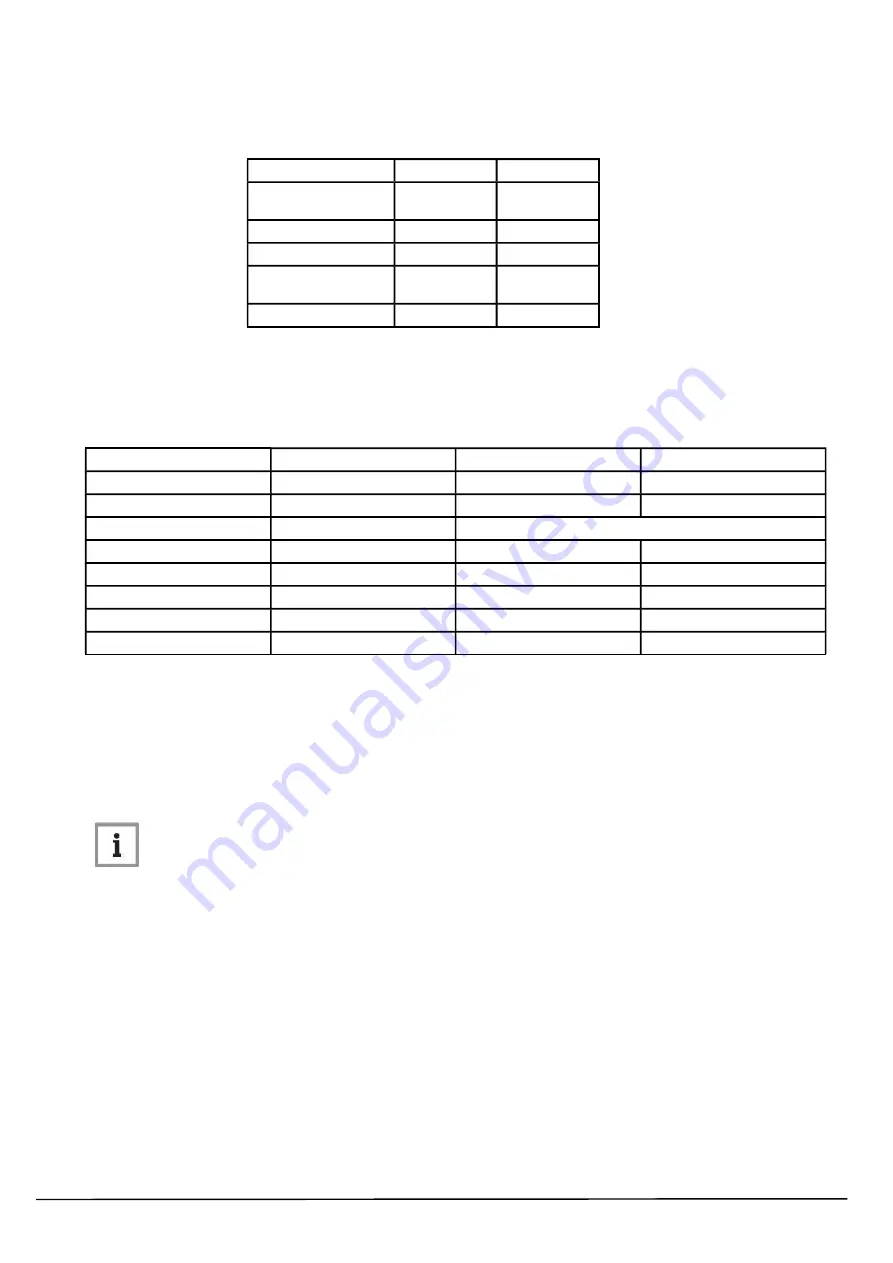

4.4.3 RECOMMENDED HEATING PUMP - MINIMUM FLOW REQUIREMENTS

The following minimum fl ow rates are recommended for use with the COMBIfl o 100 & 150 models :

Heating Load (kW)

Min fl ow rate (ltrs/hr)

Heating load (kW)

Min fl ow rate (ltrs/hr)

10

429

90

3,861

20

858

100

4,290

30

1,287

COMBIfl o 150 only

40

1,716

110

4,719

50

2,145

120

5,148

60

2,574

130

5,577

70

3,003

140

6,006

80

3,432

150

6,435

4.5 WATER CONNECTIONS

The cold water inlet and hot water outlet connection nipples are identifi ed on top of the appliance. Connect the

cold water feed and hot water outlet to these nipples with union adaptors for ease of servicing. Connect the

supplied isolating valve to the drain connection and pipe to a suitable discharge point.

(See 3.1 for connection

locations)

Do not apply excessive torque to these nipples when making connections. The use of an

appropriate potable water pipe sealing compound is recommended.

4.5.1 COLD WATER SUPPLY - SYSTEM

The appliance may be connected to an open vent or sealed system supply. When connected to a sealed sys-

tem an unvented water kit must be installed with a minimum water pressure of one bar. This appliance is factory

fi tted with temperature and pressure relief valves. An unvented system must be fi tted by an approved installer.

4.5.2 COLD WATER SUPPLY - QUALITY AND TREATMENT

In hard water areas scale formation can occur in all hot water systems and the higher the volume and hotter

the water used, the greater and more problematic the scale build-up can be. Water treatment is usually recom-

mended when the hardness levels measures greater than 150 ppm. For this reason,

base exchange water

treatment is strongly recommended in hard water areas.

FERNOX

SENTINEL

Inhibitors

Protector/

Alphi 11

X100, X500

Noise reducer

X200

Universal cleaner

Restorer

X300

Sludge remover

Protector,

Restorer

X400

Antifreeze

Alphi 11

X500

Summary of Contents for COMBIflo 100/300

Page 9: ...ANDREWS COMBIflo 7 GB 3 1 GENERAL DIMENSIONS CONNECTIONS 3 0 TECHNICAL DATA ...

Page 12: ...ANDREWS COMBIflo 10 GB 3 4 APPLICATION EXAMPLES Single Heating Circuit Simple ...

Page 13: ...ANDREWS COMBIflo 11 GB Single Heating Circuit Immersion DHW Circulation pump ...

Page 16: ...ANDREWS COMBIflo 14 GB Heating Circuit External 0 10V control ...

Page 17: ...ANDREWS COMBIflo 15 GB BMS INTERNET CONNECTIONS ...

Page 18: ...ANDREWS COMBIflo 16 GB 3 5 WIRING DIAGRAMS PCB 1 ...

Page 19: ...ANDREWS COMBIflo 17 GB PCB 2 3 ...