YORK INTERNATIONAL

80

CHECKING SUPERHEAT AND SUBCOOLING

The subcooling should always be checked when charg-

ing the system with refrigerant and/or before setting the

superheat.

When the refrigerant charge is correct, there will be no

bubbles in the liquid sightglass with the system operat-

ing under full load conditions, and there will be 10°F to

15°F subcooled liquid refrigerant leaving the condenser.

An overcharged system should be guarded against. Evi-

dences of overcharge are as follows:

a. If a system is overcharged, the discharge pressure

will be higher than normal. (Normal discharge/con-

densing pressure can be found in refrigerant tem-

perature/pressure chart; use entering air tempera-

ture +30°F for normal condensing temperatures).

b. The temperature of the liquid refrigerant out of the

condenser should not be more than 15°F less than

the condensing temperature. (The temperature cor-

responding to the condensing pressure from refrig-

erant temperature/pressure chart).

The subcooling temperature should be taken by record-

ing the temperature of the liquid line at the outlet of the

condenser and recording the liquid line pressure at the

liquid stop valve and converting it to a temperature from

the temperature/pressure chart.

Example:

LIQUID LINE PRESSURE

202 PSIG converted to

102°F

Minus Liquid Line Temperature

-90°F

Subcooling =

12°F

Record:

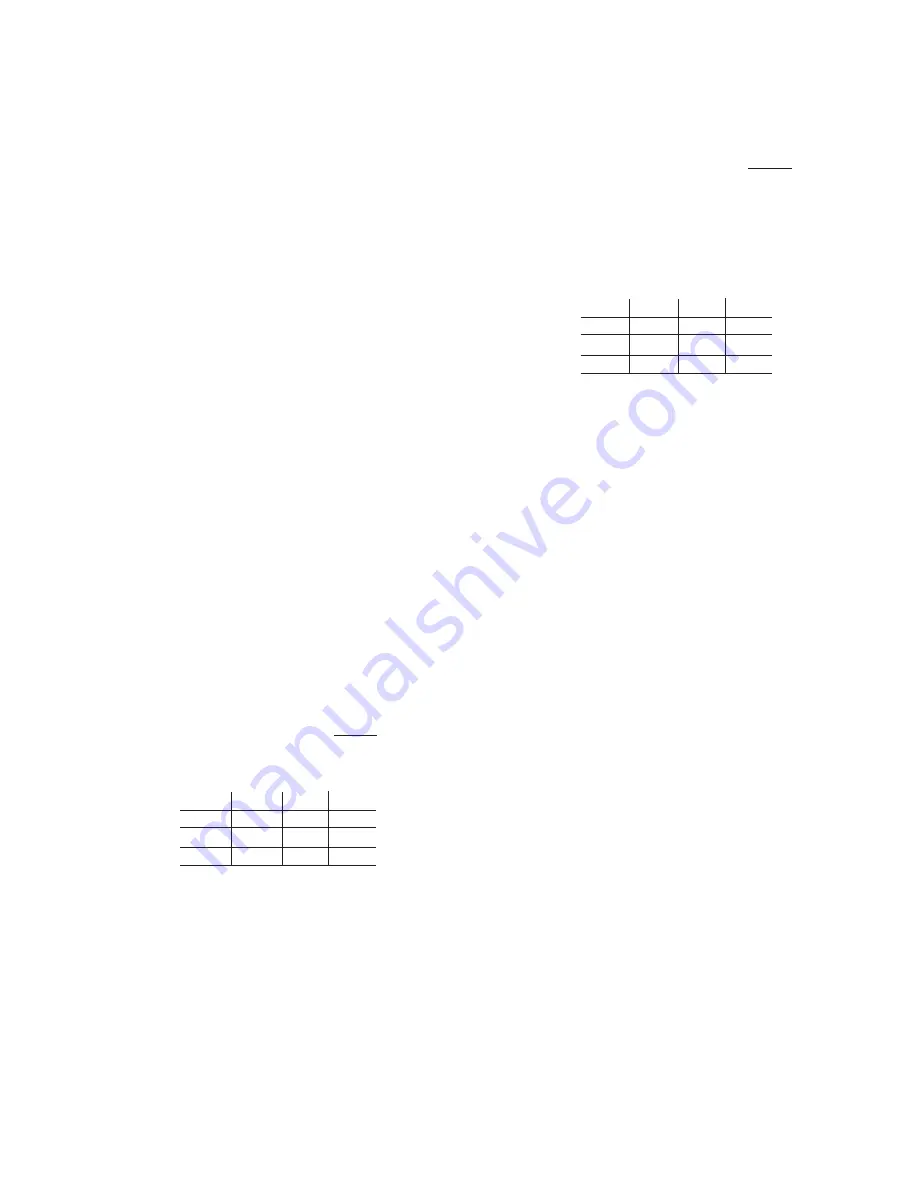

SYS 1 SYS 2 SYS 3 SYS 4

Liquid Line Press:

PSIG

Liquid Line Temp:

°F

Subcooling:

°F

After the subcooling is set at 10°-15°F the superheat

should be checked.

The superheat should be checked only after steady op-

eration of the chiller has been established, the leaving

chilled liquid has been pulled down to the required tem-

perature, and the unit is running fully loaded. Correct

superheat setting is 12°-15°F.

The superheat is the difference between the actual tem-

perature of the returned refrigerant gas entering the

compressor and the temperature corresponding to the

suction pressure as shown in a standard pressure/tem-

perature chart.

Example:

Suction Temperature

46°F

Minus Suction Pressure 60 PSIG

Converted to Temperature

- 34°F

Superheat

12°F

The suction temperature should be taken 6" before the

compressor service valve, and the suction pressure is

taken at the compressor suction service valve.

Record:

SYS 1 SYS 2 SYS 3 SYS 4

Suction Temperature:

°F

Suction Pressure:

PSIG

Superheat:

°F

Normally, the thermal expansion valve need not be ad-

justed in the field. If, however, an adjustment is to be

made, the expansion valve adjusting screw should be

turned not more than one turn at a time, allowing suffi-

cient time (approximately 15 minutes) between adjust-

ments for the system and the thermal expansion valve

to respond and return to settled operation.

If the unit has been functioning satisfactorily during the

initial operating period, it is ready for continuous opera-

tion.

¨

Leak check compressors, fittings, and piping to as-

sure no leaks are present from improper handling.

NOTES:______________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

¨

Start-Up Complete

Содержание YDAJ87HU7

Страница 4: ...YORK INTERNATIONAL 4 FIG 1 UNIT COMPONENTS Typical on each of the two modules 00023TG 00024TG...

Страница 5: ...FORM 150 75 NM2 5 YORK INTERNATIONAL FIG 1 UNIT COMPONENTS Cont d LD01910 00025TG...

Страница 24: ...YORK INTERNATIONAL 24 MASTER MODULE WIRING DIAGRAM LD01933 FIG 17 MASTER MODULE CONNECTION DIAGRAM...

Страница 30: ...YORK INTERNATIONAL 30 SLAVE MODULE WIRING DIAGRAM FIG 20 SLAVE MODULE CONNECTION DIAGRAM LD01941...

Страница 99: ...FORM 150 75 NM2 99 YORK INTERNATIONAL...