FORM 150.75-NM2

13

YORK INTERNATIONAL

For ground level installations, precautions should be taken

to protect the unit from tampering by or injury to unau-

thorized persons. Screws and / or latches on access

panels will prevent casual tampering. However, further

safety precautions such as a fenced-in enclosure or lock-

ing devices on the panels may be advisable. A tamperproof

kit is available as an option. Check local authorities for

safety regulations.

Rooftop Locations

Choose a spot with adequate structural strength to safely

support the entire weight of the unit and service per-

sonnel. Care must be taken not to damage the roof.

Consult the building contractor or architect if the roof is

bonded. Roof installations should have wooden beams

(treated to reduce deterioration), cork, rubber or vibra-

tion isolators under the base to minimize vibration.

SHIPPING BRACES

Two shipping brackets (typically galvanized steel) which

run diagonally along each side of each module, must

be removed once the unit is mounted on its foundaiton.

A third bracket on the right rear of the unit should also

be removed. This bracket runs across the bottom right

corner of the unit behind the compressors.

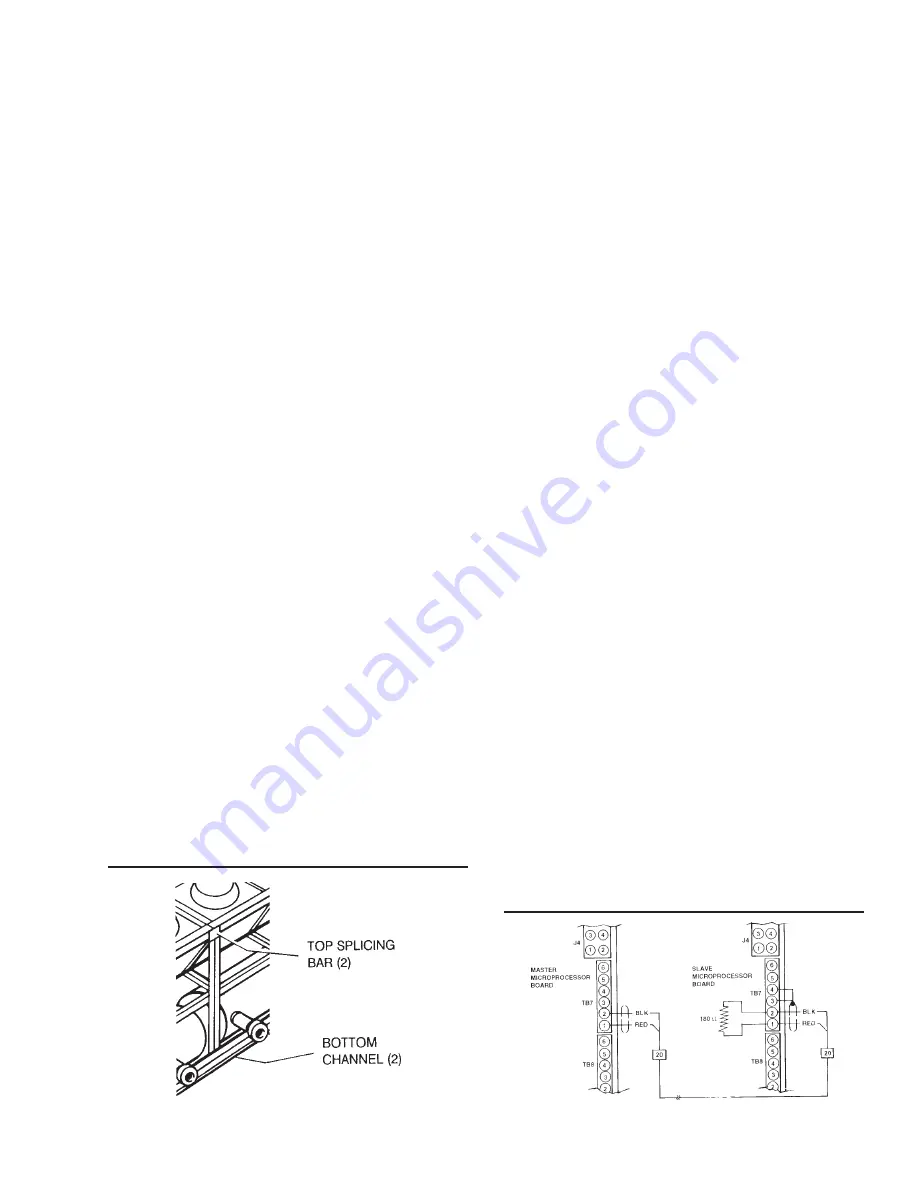

MODULAR INSTALLATION

All chillers require a Splicing Kit to connect the two

modules together. This will be field mounted. See Fig.

5). For mounting top slicing bar, loosen eight (8) exist-

ing nuts at top end of frame of both modules. Secure

top slicing bars in place, using existing nuts and bolts.

Mount bottom channel bars on both sides by loosening

eight (8) existing nuts at the bottom end channels. Se-

cure bars in place, using existing nuts and bolts. The

Splicing Kit will be shipped in a separate box.

COMMUNICATIONS LINK INSTALLATION

An RS-485 communications link MUST be connected

between the Master and the Slave Control Panels. One

of two installation procedures will be required, depend-

ing upon when the chiller was manufactured. Please

read the note below before proceeding.

NOTES: In the fall / winter of 1995, a design change

will be implemented in the communications link

to add transient protection circuit boards (LTP,

Lan Transient Protection) to the RS-485 com-

munications link. These boards are designed

to protect the RS-485 drivers on the Micro

Boards from severe RFI transients that may

enter through earth ground and cause a cir-

cuitry failure and subsequent communications

loss on chillers that have been in service.

There is no need to worry if the boards are

not included with the chiller. The boards are

designed with the intent of being used where

communications links are hundreds or thou-

sands of feet long. The circuits are being

added as a precaution / enhancement. No

prior history of failures exists on 3 and 4 com-

pressor chillers with communications between

two micropanels within the chiller. NO RET-

ROFIT IS NECESSARY!

To determine whether to follow installation pro-

cedure #1 or #2, open the control panel of the

Slave Panel and inspect the TB7 connector

on the Micro Board. If a transient Protection

Circuit board is installed, (Fig. 7A), use Pro-

cedure #2. Otherwise use Procedure #1.

Procedure #1

The 2-wire shielded cable should be connected between

TB7 of the Master and TB7 of the Slave Micro Board as

shown in Fig. 6. This cable is shipped rolled up in the

Slave Panel. Connection points to each Microproces-

sor are shown in Fig. 6. Also assure that the shield and

the 180W resistor are connected at the Slave Panels

shown in Fig. 6. Place a wire jumper between TB7-3 &

TB7-4 as shown in Fig. 6.

NOTE: DO NOT connect the shield at the MASTER

Microboard.

Cable routing should be through existing cable entry in

the bottom of the Control Panels and should follow the

center condenser support the entire length of the chiller.

FIG. 5

SPLICING KIT

FIG. 6

RS-485 WIRING CONNECTION

LD01914

LD01913

Содержание YDAJ87HU7

Страница 4: ...YORK INTERNATIONAL 4 FIG 1 UNIT COMPONENTS Typical on each of the two modules 00023TG 00024TG...

Страница 5: ...FORM 150 75 NM2 5 YORK INTERNATIONAL FIG 1 UNIT COMPONENTS Cont d LD01910 00025TG...

Страница 24: ...YORK INTERNATIONAL 24 MASTER MODULE WIRING DIAGRAM LD01933 FIG 17 MASTER MODULE CONNECTION DIAGRAM...

Страница 30: ...YORK INTERNATIONAL 30 SLAVE MODULE WIRING DIAGRAM FIG 20 SLAVE MODULE CONNECTION DIAGRAM LD01941...

Страница 99: ...FORM 150 75 NM2 99 YORK INTERNATIONAL...