FORM 150.75-NM2

11

YORK INTERNATIONAL

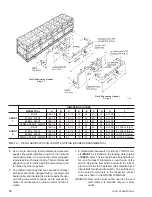

NOTES:

1. Minimum Circuit Ampacity (MCA) is based on 125% of the rated load amps for the largest motor plus 100% of the rated load amps for all

other loads included in the circuit, per N.E.C. Article 430-24. If Factory Mounted Control Transformer is provided, add the following to the

system MCA values in the Tables: -17, add 10 amps; -28, add 9 amps; -40, add 6 amps; -46, add 5 amps; -58, add 4 amps.

2. Minimum fuse size is based on 150% of the rated load amps for the; largest motor plus 100% of the rated load amps for all other loads

included in the circuit, per U.L. Standard 1995, Section 1995, Section 36.1. It is not recommended in all applications where brown outs,

frequent starting and stopping of the unit and/or operation at ambient temperatures in excess of 95°F is anticipated.

3. Maximum fuse size is based on 225% of the rated load amps for the largest motor plus 100% of the rated load amps for all other loads

included in the circuit, per N.E.C. Article 440-12A1.

4. The recommended disconnect switch is based on 115% of the rated load amps for all the loads included in the circuit, per U.L. 1995, Fig. 36.2.

5. HACR-Type circuit breakers are UL-listed circuit breakers that have been found suitable for use with heating, air conditioning and refrigeration

equipment comprising multimotor or combination loads and are marked Listed HACR-Type, refer to N.E.C. Article 440-21. Maximum HACR

circuit breaker rating is based on 225% of the rated load amps for the largest motor plus 100% of the rated load amps for all other loads

included in the circuit, per UL 1995, Fig. 36.2. Canadian and international models may not require HACR-Type circuit breakers.

6. The INCOMING WIRE RANGE is the minimum and maximum wire size that can be accommodated by unit wiring lugs. The (1), (2), (3)

or (4) preceding the wire range indicates the number of termination points available per phase of the wire range specified. The (1-2), (1-

3), or (1-4) preceding the wire range indicates that a single multi-termination lug is available per phase that can accept from two (1-2) to

four (1-4) wires of the wire range specified. (1) #1-600MCM or (2) #1-250MCM indicates that a single lug is supplied and it will accept a

single wire up to 600MCM or 2 wires up to 250MCM. Actual wire size and number of wires per phase must be determined based on

ampacity and job requirements using N.E.C. wire sizing information. The above recommendations are based on the National Electric

Code and using copper connectors only. Field wiring must also comply with local codes.

7. A ground lug is provided for each compressor system to accommodate field grounding conductor per N.E.C. Article 250-54. A control

circuit grounding lug is also supplied. Incoming ground wire range is #6 - #2/0.

8. The supplied disconnect is a Disconnection Means as defined in N.E.C. Article 100.B, and is intended for isolating the unit from the

available power supply to perform maintenance and troubleshooting. This disconnect is not intended to be a Load Break Device.

9. All unit compressors have a part winding electrical configuration such that the indicated Locked Rotor Amps are Part Wind Locked Rotor Amps.

VOLTAGE CODE

17

=

200-3-60 Hz

28

=

230-3-60 Hz

40

=

380-3-60 Hz

46

=

460-3-60 Hz

50

=

380/415-3-50 Hz

58

=

575-3-60 Hz

64

=

346-3-50 Hz

LEGEND:

VOLT

= Voltage

MCA

= Minimum Circuit Ampacity

DISC

= Disconnect

N/A

= Not Available

CPR-RLA

= Compressor Running Load Amps

CRP-LRA

= Compressor Part Winding Inrush Amps

FLA

= Full Load Amps

CKT BRK

= Circuit Breaker

HACR

= Heating, Air Conditioning and Refrigeration

CONTROL POWER SUPPLY

UNIT

CONTROL

MIN CIRCUIT

MAX DUAL

NON-FUSED

VOLTAGE

POWER SUPPLY

AMPACITY

ELEMENT FUSE SIZE

DISC. SW. SIZE

Std. Models w/o Transformers

115-1-50/60

20A

20A, 250V

30A, 240V

SYSTEM 1 OR 3

SYSTEM 2 OR 4

LOAD RATINGS

LOAD RATINGS

MODEL

VOLTAGE

CPR

CPR

FAN

CPR

CPR

FAN

YDA

CODE

LRA

9

RLA

RLA

LRA

9

RLA

RLA

EA

EA

J87HU7

-50

585

170

5.9

585

150

5.9

J87HU7

-64

668

187

5.8

668

165

5.8

J87KU6

-17

1322

403

10

1322

352

10

J87KU6

-28

1150

350

12

1150

306

12

J87KU6

-40

696

212

5.2

696

185

5.2

J87KU6

-46

575

175

5

575

153

5

J97KU7

-50

760

195

5.9

585

150

5.9

J87KU6

-58

460

140

4.9

460

122

4.9

J97KU7

-64

917

214

5.8

668

165

5.8

J88MU6

-17

1322

403

10

1322

403

10

J88MU6

-28

1150

350

12

1150

350

12

J88MU6

-40

696

212

5.2

696

212

5.2

J88MU6

-46

575

175

5

575

175

5

J98MU7

-50

760

198

5.9

585

170

5.9

J88MU6

-58

460

140

4.9

460

140

4.9

J98MU7

-64

917

217

5.8

668

187

5.8

J99MU7

-50

760

198

5.9

760

198

5.9

J99MU7

-64

917

217

5.8

917

217

5.8

J99MW6

-40

997

254

5.2

997

254

12

J99MW6

-46

830

210

5

830

210

5.2

J99MW6

-58

664

168

4.9

664

168

4.9

J99MW9

-50

760

198

9.7

760

198

9.7

J99MW9

-64

917

217

9.2

917

217

9.2

Содержание YDAJ87HU7

Страница 4: ...YORK INTERNATIONAL 4 FIG 1 UNIT COMPONENTS Typical on each of the two modules 00023TG 00024TG...

Страница 5: ...FORM 150 75 NM2 5 YORK INTERNATIONAL FIG 1 UNIT COMPONENTS Cont d LD01910 00025TG...

Страница 24: ...YORK INTERNATIONAL 24 MASTER MODULE WIRING DIAGRAM LD01933 FIG 17 MASTER MODULE CONNECTION DIAGRAM...

Страница 30: ...YORK INTERNATIONAL 30 SLAVE MODULE WIRING DIAGRAM FIG 20 SLAVE MODULE CONNECTION DIAGRAM LD01941...

Страница 99: ...FORM 150 75 NM2 99 YORK INTERNATIONAL...