YORK INTERNATIONAL

14

Ty-wrap the cable to the support as needed. Additionally,

the J19 jumper on both Microprocessor Boards MUST

be in the RS-485 position (Top 2 pins). See page 37.

Procedure #2

If a transient protection circuit board is installed in the

SLAVE PANEL (Fig. 7A), continue, otherwise, perform

Procedure #1.

Included in the Splice Kit is a second LTP Board which

is to be installed on the Master Micro Board. Install the

board as shown in Fig. 7B by carefully loosening the

terminals on TB7. Orient the board as shown with the

component side up and insert all 6 pins into TB7 as

shown. Carefully tighten each terminal.

Carefully, loosen the terminals of J1 on the LTP boards

in the Master and Slave control panels and install the

cable as shown in Fig. 8. Do not connect the shield in

the Master Panel. Assure that the shield, jumper, and

180 ohm resistor are installed in the Slave Panel LTP

board as shown in Fig. 8.

MIXED WATER TEMP. SENSOR INSTALLATION

A Mixed Leaving Water Temperature Sensor MUST be

installed in the common leaving water line coming from

the two evaporators. The sensor must be installed a

minimum of 5 pipe diameters from the intersection of

the leaving water lines. Assure that the sensor is totally

immersed in heat conductive compound. (Minnesota

Paints type #11149 or equiv.) inside the sensor well.

Connect the sensor plug to the plug which is factory

mounted on the cable. The cable should then be routed

back to the Master Control Panel. Before placing the

connector on the unterminated end of the cable, route

the cable through the hole in the bottom of the Control

Panel as shown in Fig. 9.

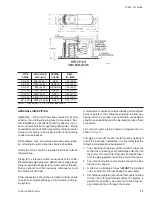

FIG. 7A

TRANSIENT PROTECTION CIRCUIT

BOARD (LTP) INSTALLED IN SLAVE

PANEL

FIG. 7B

TRANSIENT PROTECTION CIRCUIT

BOARD (LTP) INSTALLED IN MASTER

PANEL

LD01915

LD01916

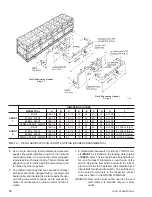

FIG. 8

COMMUNICATIONS CABLE CONNECTION

LD01917

Содержание YDAJ87HU7

Страница 4: ...YORK INTERNATIONAL 4 FIG 1 UNIT COMPONENTS Typical on each of the two modules 00023TG 00024TG...

Страница 5: ...FORM 150 75 NM2 5 YORK INTERNATIONAL FIG 1 UNIT COMPONENTS Cont d LD01910 00025TG...

Страница 24: ...YORK INTERNATIONAL 24 MASTER MODULE WIRING DIAGRAM LD01933 FIG 17 MASTER MODULE CONNECTION DIAGRAM...

Страница 30: ...YORK INTERNATIONAL 30 SLAVE MODULE WIRING DIAGRAM FIG 20 SLAVE MODULE CONNECTION DIAGRAM LD01941...

Страница 99: ...FORM 150 75 NM2 99 YORK INTERNATIONAL...