F

−

1031, Section 4321

Page 5 of 57

General Overhaul Information

Tools and Equipment

The following tools and equipment may be needed to overhaul a pump:

1. Usual automotive mechanic's hand tools.

2. An arbor press for assembling or disassembling components.

3. A suitable hoist and slings.

4. Torque capability up to 325 lb-ft (440 N•m)

While no special tools and equipment are required, a few special items are

illustrated or described so the mechanic can make them. These special items

are not absolutely necessary, but they will make the mechanic's work much

easier.

Preliminary Testing

Before disassembling a pump, test it thoroughly, if possible, and record the

results. A comparison of this test with periodic tests recommended in form

F-1031, Section 1000 can often reveal specific pump troubles. Excessive

speed, for instance, indicates that impellers and/or wear rings are probably

worn.

Cleaning

The continued satisfactory operation of a pump depends to a great extent

upon the cleanliness of its internal parts. Sand, dirt or other abrasive material

will wear gears and related parts. Before disassembling a pump for repairs, be

sure to clean its exterior. Make sure the working space, benches and tools are

clean. Use only clean, lint-free cloths to wipe off components. Before reas

sembling a pump or its components, be sure to clean them thoroughly.

Pump Bodies and Impellers

Flush out these components and related parts with clean water and remove

loose scale, caked sediment, etc. Be sure to remove all traces of old gaskets.

Examine pump bodies, covers, adapters and fittings for cracks, severe corro

sion or other damage. Almost all damage to these parts results from improper

use or maintenance, or from freezing. Replace defective parts.

Bearings, Gaskets, Seals and O-rings

Parts of this nature are frequently damaged during removal or disassembly. In

addition, they sometimes deteriorate or lose their effectiveness because of

age or misuse. Replacing these parts whenever overhauling a pump is a good

policy.

Impeller Shafts

Examine shaft for severe scratches, grooves or corrosion - especially under

O-ring seals. If scratches are not severe, and are not under seals, clean them

with a fine-cut file. Grooves are usually permissible if they are not sharp or too

deep. Even slight longitudinal scratches will cause leaks and should be re

moved.

Installing Ball Bearings

Most Waterous pumps are designed so that ball bearings fit tightly on their

shafts and have relatively loose fits in the bearing housings. When mounting

these bearings on shafts, always apply force to the inner races. When bear

ings have a tight fit in the housings, and a heavy force is necessary to install

them, be sure to apply force only to the outer bearing races. For either type of

fit, applying force to the wrong bearing race may damage the balls and race.

End Yoke and Companion Flange Nuts

Do not reuse self-locking nuts. Apply lubrication oil to the shaft threads before

removing.

Installing Oil Seals

Before installing an oil seal in a housing, be sure that the seal, shaft and hous

ing are clean. Apply force to the outer edge of the seal and press in evenly.

Содержание HL Series

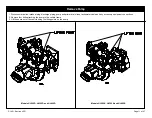

Страница 52: ...F 1031 Section 4321 Page 52 of 57 Reassembly Cross Section Views HL200D and HL300D Direct Drive Models...

Страница 53: ...F 1031 Section 4321 Page 53 of 57 HL200K and HL300K Gear Drive Models...

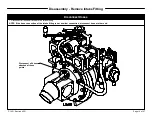

Страница 54: ...F 1031 Section 4321 Page 54 of 57 HL400D Direct Drive Model...

Страница 55: ...F 1031 Section 4321 Page 55 of 57 HL400K Gear Drive Model...