F

−

1031, Section 4321

Page 30 of 57

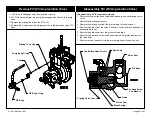

Reassembly - Inspection and Repair

Reassembly

−

Inspection and Repair

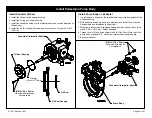

Mechanical Seal

Always install a new mechanical seal during reassembly. Follow seal installation

instructions carefully.

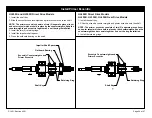

Impeller Shaft

Examine shaft for severe scratches, grooves and corrosion paying special atten

tion to oil seal and mechanical seal shaft journals. If present, replace shaft. Minor

scratches in non-critical areas will not affect pump performance. Also check for

cracks, pitting, twisted splines and damaged keyways and replace the shaft if

found.

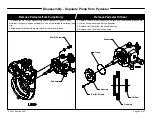

Volute Body and Intake Fitting

Examine for cracks, corrosion or other damage. Replace defective parts.

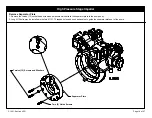

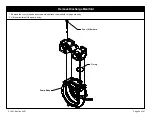

Clean out the mechanical seal weep passageways in the pump volute as shown

below.

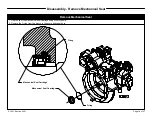

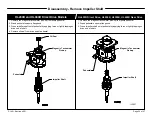

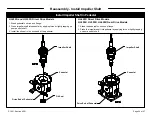

Impellers and Wear Rings

Check the wear rings and impeller hubs for deep grooves and scratches.

Wear rings are located as follows:

Main Stage Impeller:

Separate wear ring installed in pump intake fitting.

High Pressure Impeller:

Inside diameter of separator plate acts as wear ring.

Carefully measure the outside diameter of the impeller and the inside diameter

of the wear ring/separator plate.

If the difference between these measurements exceeds .020 in. / .51 mm or if

the components are scratched or grooved, replace the impeller and wear ring

separator plate.

NOTE: The wear ring may be removed from the pump intake fitting by cut

ting the ring in two places and then prying the pieces out of the intake fit

ting. Install new wear ring by pressing it into the bore in the intake fitting.

Areas to be check and cleaned.

Wear Ring

Intake Fitting

Содержание HL Series

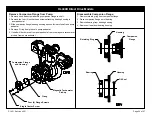

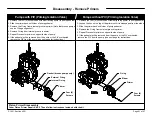

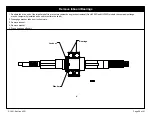

Страница 52: ...F 1031 Section 4321 Page 52 of 57 Reassembly Cross Section Views HL200D and HL300D Direct Drive Models...

Страница 53: ...F 1031 Section 4321 Page 53 of 57 HL200K and HL300K Gear Drive Models...

Страница 54: ...F 1031 Section 4321 Page 54 of 57 HL400D Direct Drive Model...

Страница 55: ...F 1031 Section 4321 Page 55 of 57 HL400K Gear Drive Model...