F

−

1031, Section 4321

Page 38 of 57

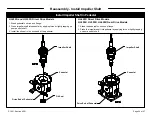

Reassembly - Shim High Pressure Impeller

Determine Amount of Shims Required

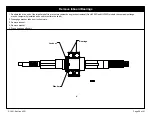

1. Using shim pack Waterous part no. 52880, install two (2) .010 in.

(.254 mm) thick shims on the impeller shaft. Note that the shim pack

includes two (2) .002 in. (.050 mm), one (1) .005 in. (.127 mm) and

three (3) .010 in. (.254 mm) shims.

2. Install impeller key and high pressure impeller.

3. Install a temporary spacer on the shaft. See Spacer Detail for fabric

ation details.

4. Install the impeller washer and locknut.

5. Restrain the companion flange on the drive end of the pump from

moving and torque locknut to 140-150 lb-ft (190-203 N•m).

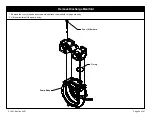

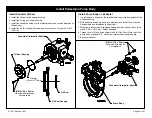

6. Check the gap measurement between the high pressure and volute

body with a depth gauge. Insert the gauge through one of the holes in

the impeller. See Depth Detail below.

7. The gauge must read between .639 and .642 (16.23 and 16.31 mm).

This dimension sets the clearance at .009 to .012 in. (.23 to .31mm).

8. If the measurement does not meet the required gauge reading, add or

remove shims until the required clearance is achieved.

9. Remove the impeller and temporary spacer leaving the correct shims on

the impeller shaft.

Impeller Key

Shims

High Pressure Impeller

Spacer

Impeller Washer

Impeller Locknut

Shims

Impeller

Balance Hole

Volute Body

High Pressure

Impeller

Spacer

Depth

Micrometer

Содержание HL Series

Страница 52: ...F 1031 Section 4321 Page 52 of 57 Reassembly Cross Section Views HL200D and HL300D Direct Drive Models...

Страница 53: ...F 1031 Section 4321 Page 53 of 57 HL200K and HL300K Gear Drive Models...

Страница 54: ...F 1031 Section 4321 Page 54 of 57 HL400D Direct Drive Model...

Страница 55: ...F 1031 Section 4321 Page 55 of 57 HL400K Gear Drive Model...