COMMISSIONING

58

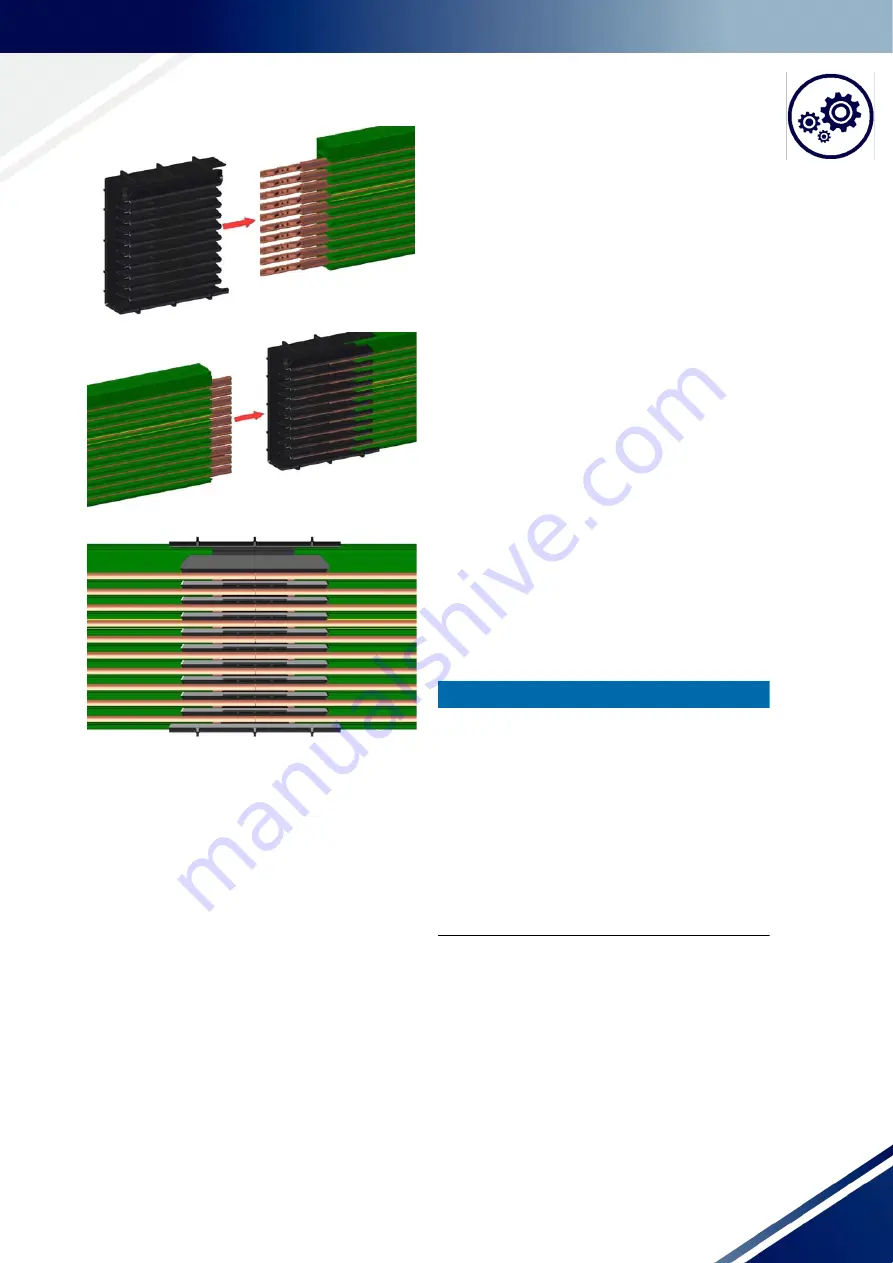

Step 5

Assembly steps:

1. Push the connector cover cap onto one side of

the section as far as it will go.

Step 6

Assembly steps:

1. Insert the next section from the front into the

hanger and snap it into place.

Step 7

Assembly steps:

1. Push the two sections together until the connec-

tors are plugged in. To do this, cover the free end

of the conductor system with an impact protec-

tion and drive the sections together using a ham-

mer to setting dimension "A" (table page 60).

NOTICE!

►

You can use an installation comb to precisely ad-

just the air gap in the copper. It is inserted be-

tween the copper conductor rails. Depending on

the air gap required

(0

- 5 mm), the various installation combs can be

used (e.g. at an installation temperature of 20°

C, the air gap is

(„A“

= 2

mm).

►

To make assembly easier, an assembly tool can

be used for the connecting joint for installation in

the HRL support profile.

Содержание VKS10

Страница 86: ...MAINTENANCE 84 Connector cap moving along the rail before Connecting cap moving along the rail after ...

Страница 87: ...MAINTENANCE 85 Reversal points moving along the rail before Reversal points moving along the rail after ...

Страница 89: ...MAINTENANCE 87 Connecting caps mast assembly before Connecting caps mast assembly after ...

Страница 96: ...PROTECTIVE MEASURES 94 10 PROTECTIVE MEASURES 10 1 EU conformity declaration ...

Страница 99: ...CE Technical Documentation DQS certified in accordance DIN EN ISO 9001 2015 OHSAS 18001 2007 ...