170

APPENDIX C — VFD INFORMATION (cont)

4. Use the UP or DOWN keys to highlight the desired

parameter and press EDIT (SOFT KEY 2).

5. Use the UP or DOWN keys to change the value of the

parameter.

6. Press SAVE (SOFT KEY 2) to store the modified value.

Press CANCEL (SOFT KEY 1) to keep the previous val-

ue. Any modifications that are not saved will not be

changed.

7. Choose another parameter or press EXIT (SOFT KEY 1)

to return to the listing of parameter groups. Continue until

all the parameters have been configured and then press

EXIT (SOFT KEY 1) to return to the main menu.

NOTE: The current parameter value appears above the high-

light parameter. To view the default parameter value, press the

UP and DOWN keys simultaneously. To restore the default

factory settings, select the application macro “HVAC Default.”

VFD Modes —

The VFD has several different modes for

configuring, operating, and diagnosing the VFD. The modes

are:

• Standard Display mode — shows drive status informa-

tion and operates the drive

• Parameters mode — edits parameter values individually

• Start-up Assistant mode — guides the start-up and

configuration

• Changed Parameters mode — shows all changed

parameters

• Drive Parameter Backup mode — stores or uploads the

parameters

• Clock Set mode — sets the time and date for the drive

• I/O Settings mode — checks and edits the I/O settings

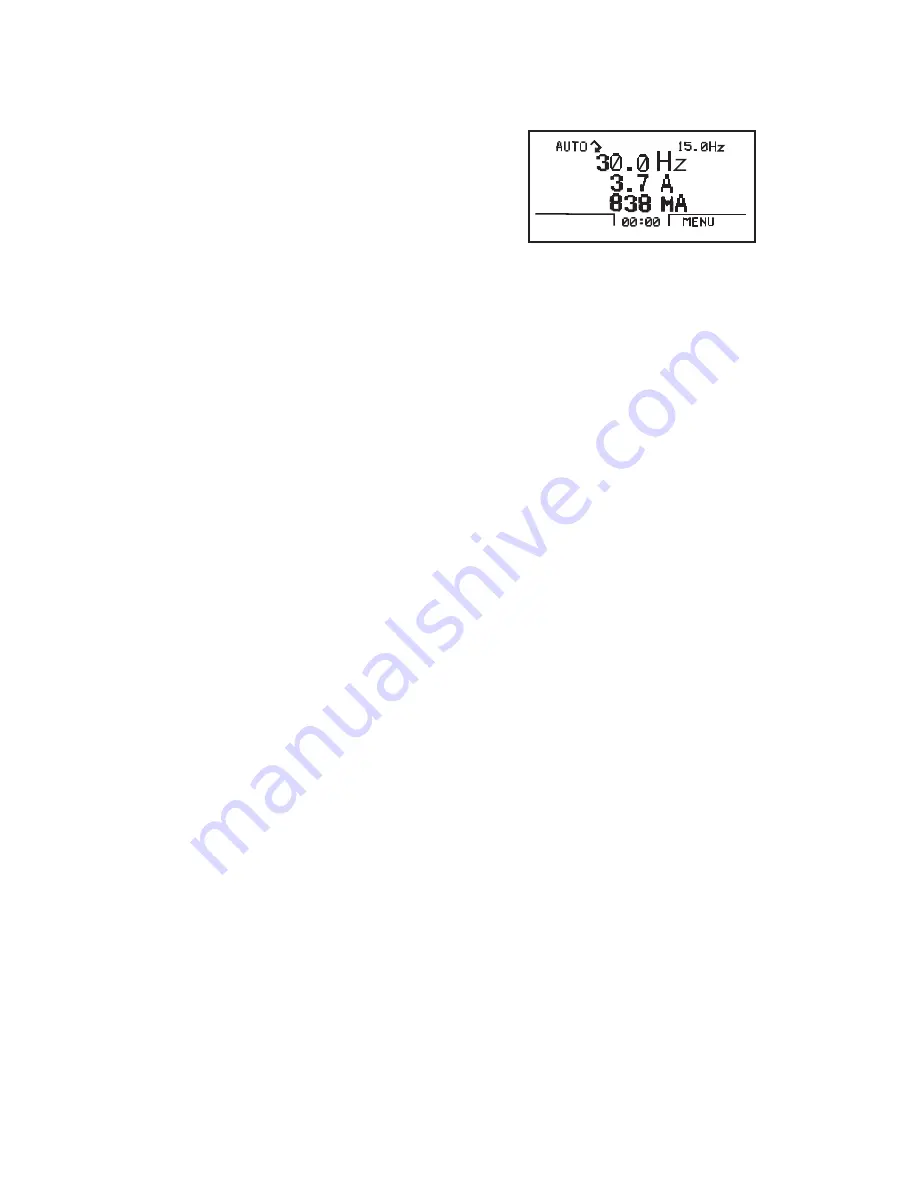

STANDARD DISPLAY MODE — Use the standard display

mode to read information on the drive status and operate the

drive. To reach the standard display mode, press EXIT until the

LCD display shows status information as described below. See

Fig. C.

The top line of the LCD display shows the basic status

information of the drive. The HAND icon indicates that the

drive control is local from the control panel. The AUTO icon

indicates that the drive is in remote control mode, such as the

basic I/O (X1) or field bus.

The arrow icon indicates the drive and motor rotation status.

A rotating arrow (clockwise or counterclockwise) indicates

that the drive is running and at setpoint and the shaft direction

is forward or reverse. A rotating blinking arrow indicates that

the drive is running but not at setpoint. A stationary arrow

indicates that the drive is stopped. For Carrier rooftop units, the

correct rotation is counterclockwise.

The upper right corner shows the frequency setpoint that the

drive will maintain.

Using parameter group 34, the middle of the LCD display

can be configured to display 3 parameter values. The default

display shows parameters 0103 (OUTPUT FREQ) in percent-

ages, 0104 (CURRENT) in amperes, and 0120 (AI1) in

milliamperes.

The bottom corners of the LCD display show the functions

currently assigned to the two soft keys. The lower middle

displays the current time (if configured to show the time).

The first time the drive is powered up, it is in the OFF mode.

To switch to local hand-held control and control the drive using

the control panel, press and hold the HAND button. Pressing

the HAND button switches the drive to hand control while

keeping the drive running. Press the AUTO button to switch to

remote input control. To start the drive press the HAND or

AUTO buttons, to stop the drive press the OFF button.

To adjust the speed in HAND mode, press the UP or

DOWN buttons (the reference changes immediately). The

reference can be modified in the local control (HAND) mode,

and can be parameterized (using Group 11 reference select) to

also allow modification in the remote control mode.

PARAMETERS MODE — The Parameters mode is used

to change the parameters on the drive. To change parameters,

perform the following procedure:

1. Select MENU (SOFT KEY 2). The Main menu will be

displayed.

2. Use the UP or DOWN keys to highlight PARAMETERS

on the display screen and press ENTER (SOFT KEY 2).

3. Use the UP or DOWN keys to highlight the desired

parameter group and press SEL (SOFT KEY 2).

4. Use the UP or DOWN keys to highlight the desired

parameter and press EDIT (SOFT KEY 2).

5. Use the UP or DOWN keys to change the value of the

parameter.

6. Press SAVE (SOFT KEY 2) to store the modified value.

Press CANCEL (SOFT KEY 1) to keep the previous

value. Any modifications that are not saved will not be

changed.

7. Choose another parameter or press EXIT (SOFT KEY 1)

to return to the listing of parameter groups. Continue until

all the parameters have been configured and then press

EXIT (SOFT KEY 1) to return to the main menu.

NOTE: The current parameter value appears above the high-

light parameter. To view the default parameter value, press the

UP and DOWN keys simultaneously. To restore the default

factory settings, select the Carrier application macro.

START-UP ASSISTANT MODE — To use the Start-Up

Assistant, perform the following procedure:

1. Select MENU (SOFT KEY 2). The Main menu will be

displayed.

2. Use the UP or DOWN keys to highlight ASSISTANTS

on the display screen and press ENTER (SOFT KEY 2).

3. Use the UP or DOWN keys to highlight Commission

Drive and press SEL (SOFT KEY 2).

4. The Start-Up Assistant will display the parameters that

need to be configured. Select the desired values and press

SAVE (SOFT KEY 2) after every change. The process

will continue until all the parameters are set. The assistant

checks to make sure that entered values are in range.

The assistant is divided into separate tasks. The user can

activate the tasks one after the other or independently. The

tasks are typically done in this order: Application, References

1 and 2, Start/Stop Control, Protections, Constant Speeds, PID

Control, Low Noise Setup, Panel Display, Timed Functions,

and Outputs.

Fig. C — Standard Display Example

A48-7713

Содержание Carrier Weathermaker 48A2

Страница 105: ...105 Fig 20 Typical Main Control Box Wiring Schematic 48 50A2 A3 A4 A5 Units...

Страница 106: ...106 Fig 21 Typical Auxiliary Control Box Wiring Schematic...

Страница 107: ...107 Fig 22 Typical 2 Stage Gas Heat Wiring Schematic Size 060 Units Shown a48 8357...

Страница 108: ...108 TO NEXT PAGE Fig 23 Typical Staged Gas Heat Wiring Schematic Size 060 Units Shown A48 7296...

Страница 109: ...109 Fig 23 Typical Staged Gas Heat Wiring Schematic Size 060 Units Shown cont A48 8358...

Страница 110: ...110 Fig 24 Typical Electric Heat Control Schematic 50 Series Size 060 Units Shown a50 8228...

Страница 111: ...111 Fig 25 Typical Power Schematic 48 50A2 A3 A4 A5 060 Unit Shown...

Страница 112: ...112 Fig 26 Typical Low Ambient Controls Option Wiring...

Страница 113: ...113 Fig 27 Typical Small Chassis Component Location Size 020 035 Units...

Страница 114: ...114 Fig 28 Typical Large Chassis Component Locations Size 040 060 Units...

Страница 118: ...118 Fig 30 Economizer Control Board ECB1 and VAV Control Board ECB2 A48 7706...

Страница 142: ...142 A48 3733 Fig 56 Main Burner Removal...

Страница 176: ...176 APPENDIX C VFD INFORMATION cont Fig F Internal Enclosure Fan Replacement A48 7716...