P06717

S00109

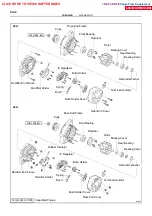

Water Pump

Crank Shaft

Alternator

98 N

P06723

CORRECT

WRONG

WRONG

--

CHARGING

CHARGING SYSTEM

CH--3

5. INSPECT DRIVE BELT

(a)

Visually check the belt for excessive wear, frayed cords

etc.

If any defect has been found, replace the drive belt.

HINT:

Cracks on the rib side of a belt are considered acceptable. If the

belt has chunks missing from the ribs, it should be replaced.

(b)

Check the drive belt deflection by pressing on the belt at

the points indicated in the illustration with 98 N (10 kgf, 22

lbf) of pressure.

Drive belt deflection:

New belt 5 -- 7 mm (0.20 -- 0.28 in.)

Used belt 7 -- 8 mm (0.28 -- 0.31 in)

If necessary, adjust the drive belt deflection.

Reference

(c)

Using a belt tension gauge, measure the belt tension.

Belt tension gauge:

Denso BTG--20 (95506--00020)

Borroughs No. BT--33--73F

Drive belt tension:

New belt 520 -- 750 N (53 -- 77 kgf)

Used belt 295 -- 392 N (30 -- 40 kgf)

If the belt tension is not as specified, adjust it.

HINT:

S

”New belt” refers to a belt which has been used less

than 5 minutes on a running engine.

S

”Used belt” refers to a belt which has been used on

a running engine for 5 minutes or more.

S

After installing a belt, check that it fits properly in the

ribbed grooves.

S

Check with your hand to confirm that the belt has

not slipped out of the groove on the bottom of the

pulley.

S

After installing a new belt, run the engine for about

5 minutes and recheck the belt tension.

6 . V I S UALLY CHE CK ALTE RNATO R WI RI NG AND

LI S T E N FO R ABNO RMAL NO I S E S

(a)

Check that the wiring is in good condition.

(b)

Check that there is no abnormal noise from the alternator

while the engine is running.

7. INSPECT DISCHARG E WARNI NG LI G HT CI RCUI T

(a)

Turn the ignition switch ”ON”. Check that the discharge

warning light comes on.

(b)

Start the engine. Check that the light goes off.

If the light does not operate as specified, troubleshoot the dis-

charge warning light circuit.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE