Z11078

(1)

(2)

(3)

P14910

Service Bolt

SST

Turn

P14672

Straight Pin

P14711

P15749

10

9

8

7

6

5

4

3

2

1

--

ENGINE MECHANICAL

CYLINDER HEAD (2RZ--FE)

EM--55

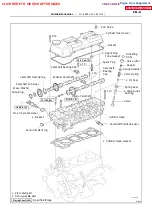

3. ASSEMBLE EXHAUS T CAMS HAFT

(a)

Mount the hexagon wrench head portion of the camshaft

in a vise.

NOTICE:

Be careful not to damage the camshaft.

(b)

Install these parts:

(1)

Camshaft gear spring

(2)

Camshaft sub--gear

(3)

Wave washer

HINT:

Align the pins on the gears with the spring ends.

(c)

Using snap ring pliers, install the snap ring.

(d)

Using SST, align the holes of the camshaft main gear and

sub--gear by turning sub--gear clockwise, and install a

service bolt.

SST 09960 -- 10010 (09962 -- 01000, 09963 -- 00500)

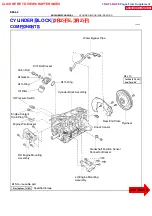

4 . I NS TALL CAMS HAFTS

NOTICE:

Since the thrust clearance of the camshaft is small, the

camshaft must be kept level while it is being installed. If the

camshaft is not kept level, the portion of the cylinder head

receiving the shaft thrust may crack or be damaged, caus-

ing the camshaft to seize or break. To avoid this, these

steps should be carried out.

(a)

Install intake camshaft.

(1)

Apply MP grease to the thrust portion of the intake

camshaft.

(2)

Place the intake camshaft with knock pin facing up-

ward of camshaft angle on the cylinder head.

(3)

Install the bearing caps in their proper locations.

(4)

Apply a light coat of engine oil on the threads and

under the heads of the bearing cap bolts.

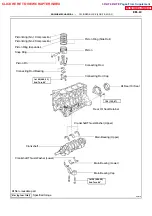

(5)

Install and uniformly tighten the 10 bearing cap

bolts in the sequence shown.

Torque: 15.5 N

∙

m (160 kgf

∙

cm, 12 ft

∙

lbf)

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE