P14803

P14813

--

ENGINE MECHANICAL

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

EM--75

Size to be rebored = P + C -- H

P = Piston diameter

C = Piston clearance

0.057 -- 0.080 mm (0.0022 -- 0.0031 in.)

H = Allowance for honing

0.020 mm (0.0008 in.) or less

(c)

Bore and hone cylinder to calculated

dimensions

Maximum honing:

0.02 mm (0.0008 in.)

NOTICE:

Excess honing will destroy the finished roundness.

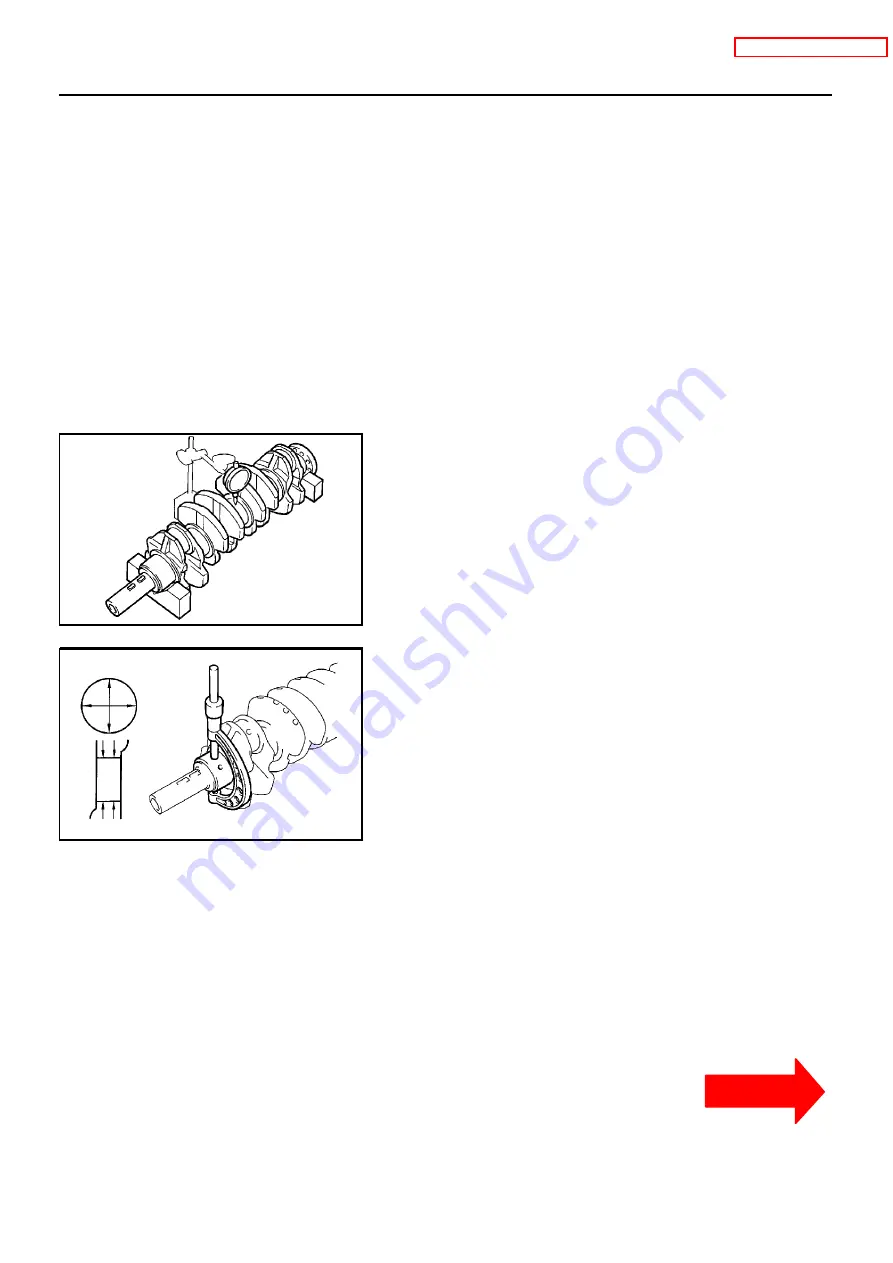

18. INSPECT CRANKS HAFT F O R RUNO UT

(a)

Place the crankshaft on V--blocks.

(b)

Using a dial indicator, measure the circle runout at the

center journal.

Maximum circle runout:

0.03 mm (0.0012 in.)

If the circle runout is greater than maximum, replace the crank-

shaft.

19. INSPECT MAIN J OURNALS AND CRANK P I NS

(a)

Using a micrometer, measure the diameter of each main

journal and crank pin.

Main journal diameter:

STD

No.3

59.981 -- 59.994 mm (2.2615 -- 2.3620 in.)

Others

59.987 -- 60.000 mm (2.3617 -- 2.3622 in.)

U/S 0.25

No.3

59.740 -- 59.750 mm (2.3520 -- 2.3524 in.)

Others

59.745 -- 59.755 mm (2.3522 -- 2.3526 in.)

Crank pin diameter:

STD

52.987 -- 53.000 mm (2.0861 -- 2.0866 in.)

U/S 0.25

52.745 -- 52.755 mm (2.0766 -- 2.0770 in.)

If the diameter is not as specified, check the oil clearance

(See

. If necessary, grind or replace the crankshaft.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE