V 08425

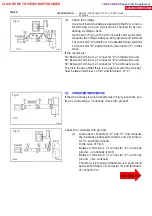

LOCK

KNK

E 6 Connec tor

(a) Remove the glove compartment

(

b) D is connect the E 6 connector of ECM.

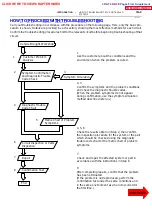

INSPECTION PROCEDURE

Replace knock sensor.

1 Check continuity between terminal KNK of ECM connect or and body ground.

OK:

Measure resistance between terminal K N K of E C U connector

and body ground.

Resistance: 1M. or higher

Connector being checked is connected.

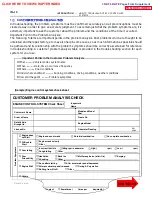

D

Indicates the condition of the connector of ECU during the check .

PREPARATION :

CHECK:

2

Go to step 3.

OK

OK

NG

D

Indicates the position of the ignition switch during the check .

Check from the connector back side.

( with harness )

Ignition Switch LOCK (OFF)

Ignition Switch START

LOCK

Ignition Switch ON

Ignition Switch ACC

START

ON

ACC

D

Inspection Procedure

Use the inspection procedure to determine

if the circuit is normal or abnormal, and, if

it is abnormal, use it to determine whether

the problem is located in the sensors ,

actuators , wire harness or ECU.

D

Indicates the place to check the voltage or resistance.

D

Indicates the connector position to checked, from the front or back side.

Connect or being checked is disconnected.

Check from the connector front side. ( without harness )

In this case, care must be taken not to bend the terminals .

E 6 Connector

KNK

Wire Harness

E 6 Connector

KNK

A 00255

AB0117

A 00265

IN -- 20

--

INTRODUCTIO N HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE