Maintenance and Lubrication: 0B-9

6) Install the camshafts. Refer to “Engine Top Side

Assembly in Section 1D (Page 1D-21)”.

7) Rotate the engine so that the tappet is depressed

fully. This will squeeze out oil trapped between the

shim and the tappet that could cause an incorrect

measurement, then check the clearance again to

confirm that it is within the specified range.

8) After finishing the tappet clearance adjustment,

reinstall the removed parts. Refer to “Engine Top

Side Assembly in Section 1D (Page 1D-21)”.

Spark Plug Replacement

B931G20206004

Replace spark plug

Every 6 000 km (4 000 miles)

Refer to “Spark Plug Cap and Spark Plug Removal and

Installation in Section 1H (Page 1H-3)”.

Spark Plug Inspection and Cleaning

B931G20206005

Inspect spark plug

Every 2 000 km (1 200 miles, 6 months)

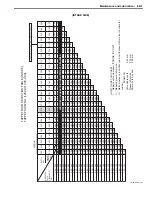

Heat Range

1) Remove the spark plug. Refer to “Spark Plug Cap

and Spark Plug Removal and Installation in Section

1H (Page 1H-3)”.

2) Check spark plug heat range by observing electrode

color.

If it appears white or glazed, replace the spark plug

with colder type one.

Heat range

3) After finishing the spark plug inspection, reinstall the

removed parts.

Carbon Deposits

1) Remove the spark plug. Refer to “Spark Plug Cap

and Spark Plug Removal and Installation in Section

1H (Page 1H-3)”.

2) Check carbon deposits on the spark plug.

If carbon is deposited, remove it using a spark plug

cleaner machine or carefully use a tool with a

pointed end.

3) After finishing the spark plug inspection, reinstall the

removed parts.

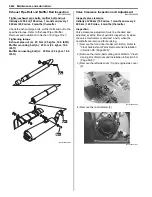

Spark Plug Gap

1) Remove the spark plug. Refer to “Spark Plug Cap

and Spark Plug Removal and Installation in Section

1H (Page 1H-3)”.

2) Measure the spark plug gap using a wire gauge.

Adjust the spark plug gap if necessary.

Spark plug gap

0.7 – 0.8 mm (0.028 – 0.030 in)

3) After finishing the spark plug inspection, reinstall the

removed parts.

Electrodes Condition

1) Remove the spark plug. Refer to “Spark Plug Cap

and Spark Plug Removal and Installation in Section

1H (Page 1H-3)”.

2) Check to see the worn or burnt condition of the

electrodes.

If it is extremely worn or burnt, replace the plug. And

also replace the plug if it has a broken insulator, or

damaged thread.

3) After finishing the spark plug inspection, reinstall the

removed parts.

CAUTION

!

Check the thread size and reach when

replacing the spark plug. If the reach is too

short, carbon will be deposited on the screw

portion of the spark plug hole and engine

damage may result.

Standard

Cold type

NGK

CR6E

CR7E

DENSO

U20ESR-N

U22ESR-N

I649G1020010-02

I831G1020092-01

Содержание 2009 LT-A750XK9

Страница 2: ......

Страница 4: ......

Страница 5: ...SUPPLEMENTS L LT A750XK9 09 MODEL 10 LT A750XPK9 09 MODEL 11 ...

Страница 29: ...0A 15 General Information 99565 01010 013 CD ROM Ver 13 ...

Страница 57: ...0B 28 Maintenance and Lubrication 09915 40610 Oil filter wrench Page 0B 12 Page 0B 12 ...

Страница 68: ...0C 11 Service Data ...

Страница 310: ...1K 5 Exhaust System ...

Страница 482: ...4D 6 Parking Brake ...

Страница 528: ...6B 13 Steering Handlebar ...

Страница 555: ...Exterior Parts 9D 1 Body and Accessories Exterior Parts Repair Instructions Exterior Parts Construction B831G29406001 ...

Страница 581: ......

Страница 631: ...4A 6 Brake Control System and Diagnosis ...