8PQ9801-8AA61

A1 en

ALPHA 3200 Eco

Commissioning - log

(Example)

Mechanical Inspection of Low Voltage Switchboards

1. Data to identify the object inspected:

Log-No: ..........................

See rating plate located in the left-hand end section of the switchboard, inside of the section or upper compartment door.

Client

:

....................................................

Location:

....................................................

Country:

....................................................

Switchboard or part:

....................................................

Type:

....................................................

Manufacturer ident. (factory) No.:...................................................

Rated operational voltage:

....................................................

Rated short-time current:

....................................................

2. Switchgear room:

Room ident.: ..................

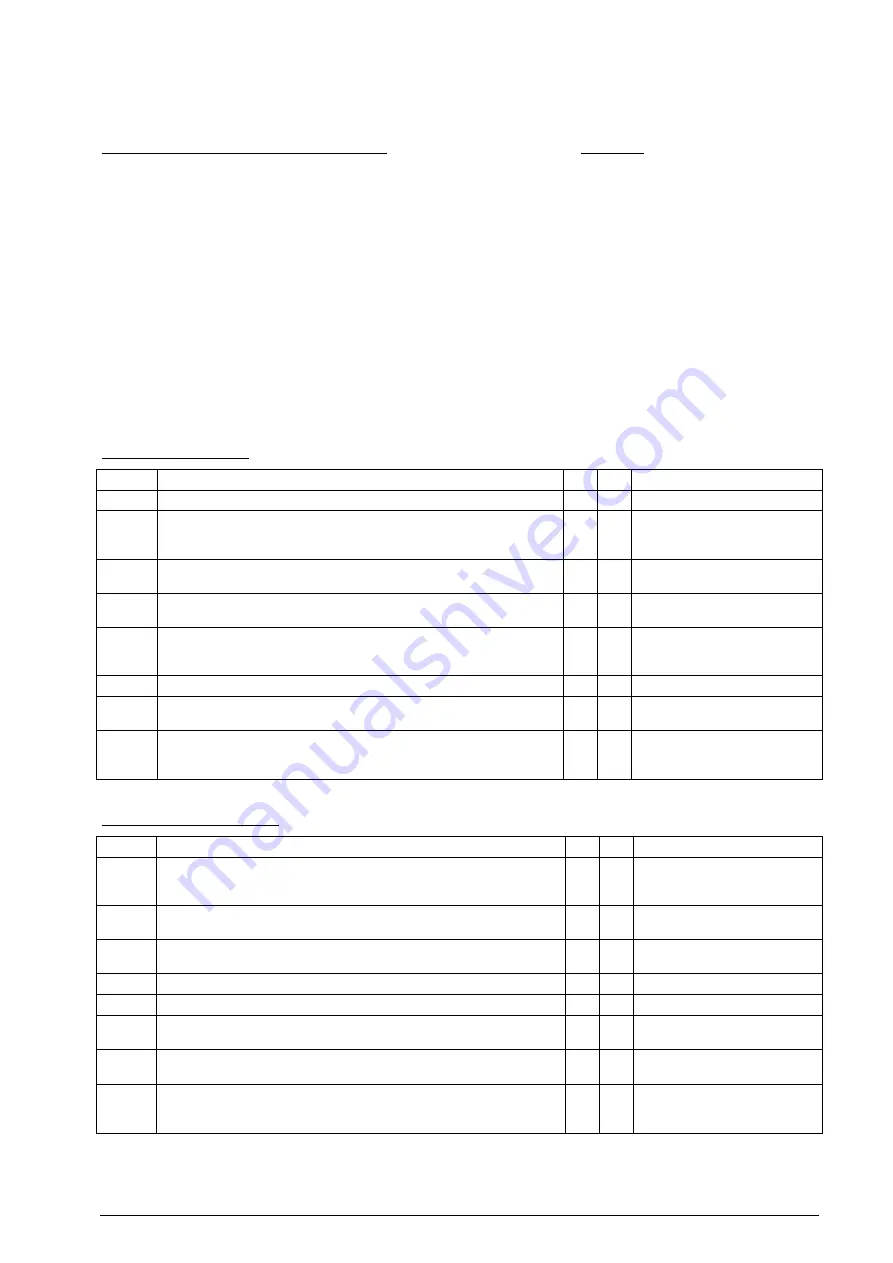

Item No.

Commissioning Step Performed

Yes

No

Remarks

2.1

The room can be properly secured against unauthorized access (locked).

2.2

All necessary measures have been taken to ensure the room meets the

local safety standards.

(e.g. escape routes, emergency lighting, fire-fighting facilities, signs)

2.3

The ventilation and air extraction works.

(air-conditioning functions, ventilation slots not obstructed)

2.4

The means for transporting heavy switchgear / withdrawable units

provided in the specified quantity and in good condition.

2.5.1

The switchboard accessories are complete according to documentation

(e.g. double-bit key, fuse grip, lamp installer, operating tool for

withdrawable circuit breakers and withdrawable units).

2.5.2

The switchboard accessories are in good condition.

2.5.3

The switchboard accessories are stored in a suitable place (easy access,

neatly arranged, protected against damage and theft).

2.6

Notices indicating the location of the switchboard documentation are

provided at visible positions in the switch room (e.g. where the tools are

kept).

3. Switchboard, General

Item No.

Commissioning Step Performed

Yes

No

Remarks

3.1

The switchboard documentation is complete, sorted and accessible at the

given location (e.g. operating instructions of switchboard and relevant

switchgear as well as updated device listings and circuit diagrams).

3.2.1

The designation of the switchboards is complete

(switchboard, section and feeder designations).

3.2.2

All connectors, terminals, and other cable connection points are labeled

correctly and completely.

3.2.3

Marking of external cables is correct and complete (if required).

3.2.4

Equipment identifiers are complete.

3.2.5

Main busbar markings have been replaced if damaged.

(L1, L2, L3, N, PEN, L+, L-).

3.3

Insulation test has been performed. If R > 1000

W

/V of the rated operational

voltage, faults have been tracked and eliminated.

3.4

The switchboard documentation has been revised (if necessary) and sets

of revised copies have been distributed to all necessary organization units

and to the switchboard manufacturer.

Содержание 8PQ9801-8AA54

Страница 1: ...Handbuch Energieverteiler bis 3200 A 01 2020 Ausgabe ALPHA 3200 Eco www siemens de verteilersysteme ...

Страница 2: ......

Страница 4: ......

Страница 32: ......

Страница 73: ...8PQ9801 8AA54 9 ...

Страница 78: ...4 8PQ9801 8AA56 1 Aufbau Sammelschienensystem 1 Horizontal busbar design PE N PEN L1 L2 L3 N PEN PE ...

Страница 84: ...10 8PQ9801 8AA56 3 2 PE Verbindung 3 2 PE joint PE Lage oben PE location top PE Lage unten PE location bottom ...

Страница 87: ...8PQ9801 8AA56 13 ...

Страница 128: ......