SYSTEM DESCRIPTION

3

29

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

O P E R A T I N G I N S T R U C T I O N S | Master Data Analyzer

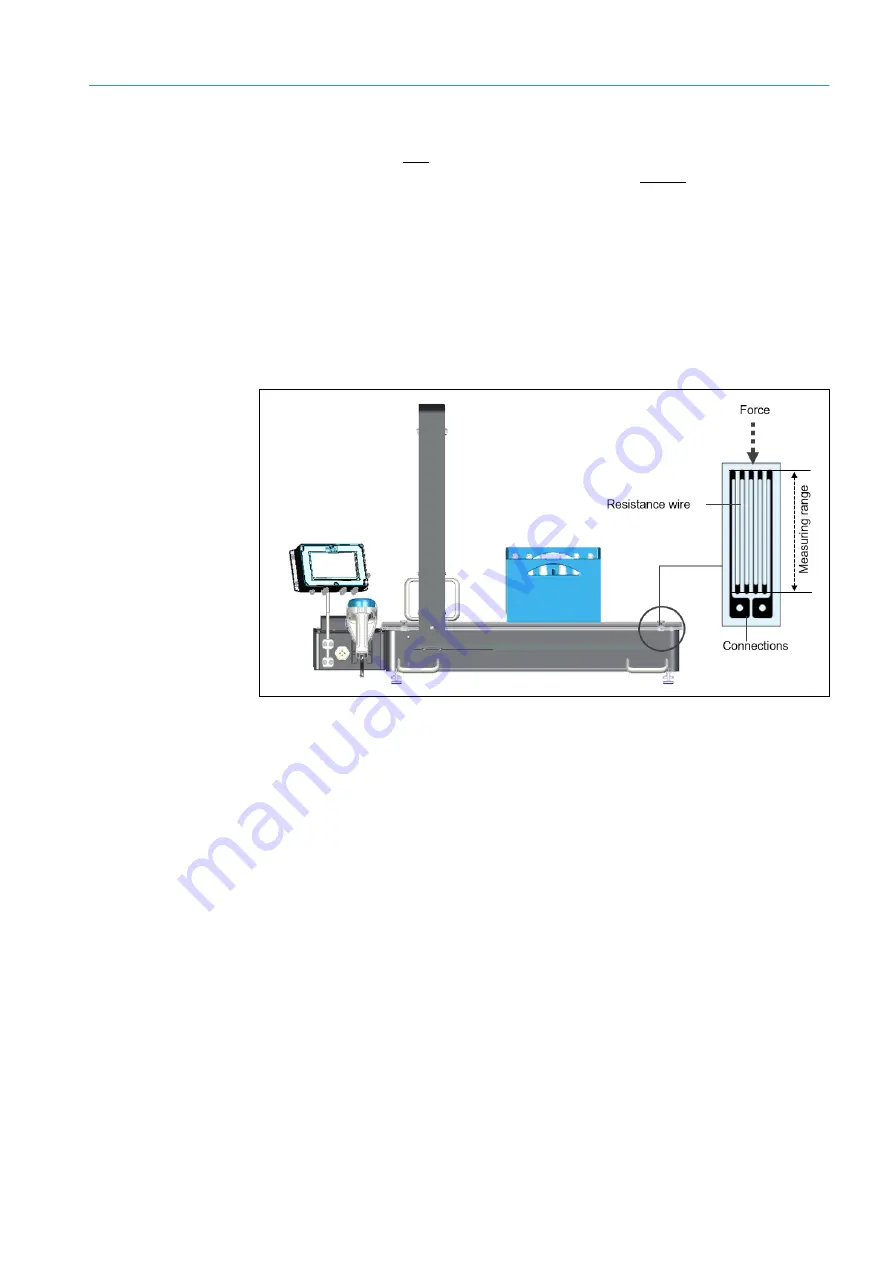

Weighing process

In the operating mode with bar code scanning, the weighing process takes place in

parallel to the volume measurement; in the operating mode without bar code scanning,

the weight is calculated once the object has been positioned, i.e., before the volume

measurement.

The weighing cells determine the weight of the object by using the four recording points at

the corners of the glass panel whilst the object is situated on the glass panel.

The electronic scales use weighing cells with strain gauges to bear the weight to be

measured. Strain gauges are metallic conductors which convert mechanical actions of

force into an electronic signal. Strain gauge weighing cells use the physical principle that

an electrical conductor changes its electrical resistance as a result of mechanical

changes.

Fig. 18: Operating principle – Weighing process

If a load is placed on the glass panel, this causes the strain gauges to deform. As a result

of this deformation causing the resistance in the strain gauges to change, the weight of

the load can be determined by using the electronic scales. The greater the deformation,

the greater the resistance due to the strain and, as a result, the heavier the weight of the

measured object.

In order to achieve maximum measurement accuracy, the electronic signal resulting from

the change in resistance is converted to a digital signal by an integrated A/D converter

(analog-digital transducer).

The weight recorded is then shown on the display. It is added to the bar code already

displayed.

If the weight value of an object is outside of the pre-configured absolute limit values, this

is output as an error in the measurement report.