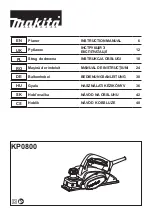

english 13

Joining, Fig. 8

Use the work stopper for this purpose, leave the planer

shaft protector on the table and set the protective rails to

the width of the work piece. Push the work piece against

the planer stopper and then lead it over the planer shaft

with both hands. As long as the board reaches high

enough on the receiving table, put the left hand on it and

shift it without interruption over the blade shaft.

Planer work – shavings emission, Fig. 9

While work, the work table must be locked. The extraction

tube should be connected to the extraction hood. When

connected to the extraction unit can then be extracted.

Extraction connection caliber 100mm

Planer thicknessing – machine adjustment, Fig. 10.1

Set the work table high and open it. Adjust the height to

the highest possible. Set a high pivot and heighten (bolt).

Attach the extraction connections and tighten the knurled

screw. When connected to the extraction unit can then be

extracted.

Planer thicknessing – table adjustment, Fig. 10.2

The height of the thicknessing table is adjustable by a

hand wheel. The integrated position gauge indicates aper-

ture height from 5 to 210 mm.

One rotation of the hand wheel corresponds to 2 mm Keep

the thicknessing table and the work table free of resin.

Shaving thicknes max. 3 mm. The graduation lines on the

graduated collar make a fine adjustment possible, where-

by 1 graduation line corresponds to 0, 05 mm.

• V-belt tension motor, Fig. 11, 12, 12.1 + 12.2

Warning!

re-tighten the flat belt and v-belt after the first 3 hours of op-

eration. then check the belt tension and regularly re-tighten,

if necessary, after 40 operating hours.

• Remove 4 hexagon sockets on both inner sides of the

encasing, Fig. 11.

• Remove both side walls.

• Losen clamping nut A on both sides (Fig. 13.1 +

13.2).

• Push the motor seesaw down.

• Tighten clamping nut A on both sides.

• Attach the side walls.

V-belt feeder cylinders, Fig. 11, 12 + 13.3

• Remove 4 hexagon sockets on both inner sides of the

encasing, Fig. 11 + 12.

• Take off the sides.

• Losen 4 hexagon nuts B, Fig. 13.3.

• Adjust belt tension.

• Tighten 4 hexagon nuts B.

• Loosen the “C” screw, tighten the v-belt, then re-tight-

en the “C” screw

• Attach the side walls.

Feeder cylinders adjustment, Fig. 14

To guarantee an efficient feeder the pressure springs must

be set to the adjacent dimensions.

changing of the feederfeeder cylinder, Fig. 15

The coating of feeder cylinders is from abrasion-resistant

rubber. After long-term great operational demand they can

suffer from abrasion, which will lead to a change of feed-

er-feeder cylinder.

1 Feeder cylinder

2 Support clip

3 Chain wheel

4 Spiral pivot

5 Pressure springs

6 Hexagon nut

• Perform the change as follows

• Remove 4 hexagon sockets on both inner sides, Fig.

11 + 12.

• Take off the sides.

• Take off feeder chain.

• Remove feeder cylinder (1) with a hexagon nut (6).

• Transfer the chain wheels to the new feeder cylinder.

• Install the new feeder cylinders.

• At the end, put the machine together again.

WOrK tABle sAFety

To prevent accidental closure of the work table, it is

equipped with a hinge shear. When closing the table no

special safety precautions need to be taken.

Work table, Fig. 6.1

The planer work chip removal is adjustable with the joint

lever 1 in 0 – 3 mm steps.

The work table can get displaced during the time of use

and an accurate to dimensions shavings removal is no

longer possible. In this case, the hexagon screws need

retightening, so that the work table could perform the ac-

curate shavings removal on its own.

m

residual risks

the machine is built according to the technical standard and

the recognized technical safety regulations. However, certain

residual risks can occur while operating.

• Risk of injury for fingers and hands by the rotating

planer shaft during improper manipulation of the work

piece.

• Injuries by a slipped work piece during improper han-

dling or manipulation, such as working without the

stopper.

• Health hazard from dust or wood shavings.

• Always wear personal protective equipment, such as

eye protection and dust mask. Use the extraction out-

let!

• Health hazard from noise. While operating, the noise

level will exceed the acceptable. Always wear personal

protective equipment, such as ear plugs.

• Hazard from electricity in case of usage of a defective

electrical power line.

• Process only selected woods without faults as: knots,

cross rifts, surface cracks. Bad wood will lead to risks

while operating.

• In addition, obvious residual risks exist despite all pre-

cautions taken.

• Residual risks can be minimized by observing the safe-

Содержание 190220290

Страница 83: ...rom n 81 75 75 75 6 1 1 0 3 90 120 6 2 7 75 75 1 2 8 9 100 10 1 10 2 5 210 2 3 1 0 05 11 12 12 1 12 2 3 40...

Страница 84: ...82 rom n 4 11 13 1 13 2 A 11 12 13 3 4 11 12 4 B 13 3 4 14 15 1 2 3 4 5 6 4 11 12 6 1 6 1 0 3 16 2...

Страница 87: ...1 rom n 85...

Страница 116: ...114...

Страница 117: ...115 80 international...

Страница 118: ...116 78 international...

Страница 119: ...117 international 79...

Страница 120: ...118 80 international...

Страница 121: ...119 international 81...

Страница 122: ...120 82 international...

Страница 123: ...121 international 83...

Страница 124: ...122 84 international...

Страница 125: ...123 international 85 71370045 71370046 06 06 2008...

Страница 126: ...124 0RWRU EURZQ EOXH EODFN UHG ZKLWH EOXH EODFN 8 EOXH EODFN EURZQ 9 9 8 8 0RWRU JUH 9 9 8...

Страница 127: ...125...

Страница 128: ...126...