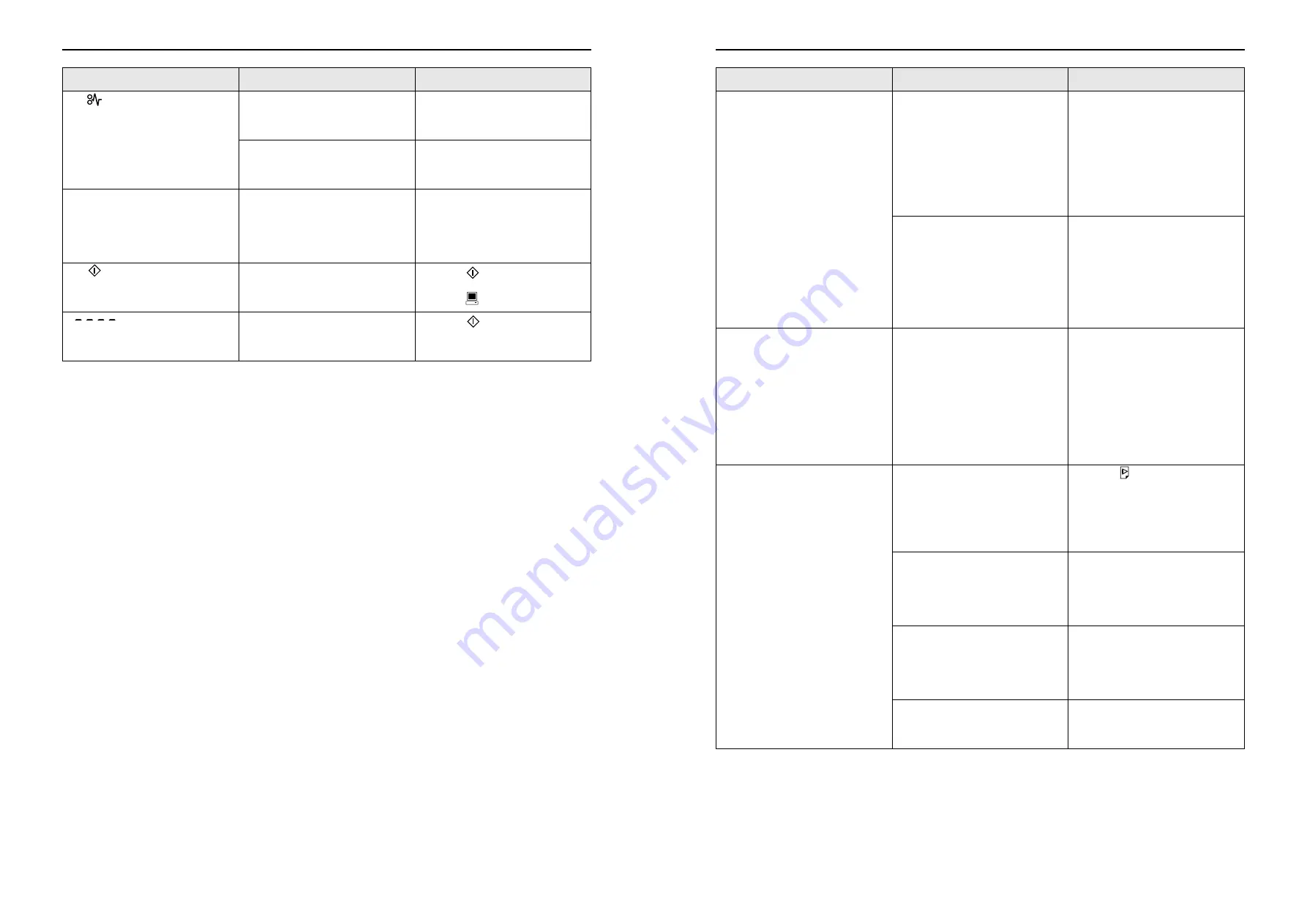

Troubleshooting

Troubleshooting Tips

96

The

indicator lights even when a

paper jam has not occurred.

Lifted paper was ejected at the time

of the second rotation of the Print

Cylinder(Drum).

Check the printed copies, and if the

top margin is less than

3

/

16

"(5 mm),

slightly lower the print position.

Because sunlight was projected to

the machine, the sensor did not

function correctly.

Use a curtain for example to shut out

sunlight or move the machine to a

place free from direct sunlight.

The machine repeats the master-

making process for each original.

“Collate Copies” or “Collate” was

selected for printer driver settings for

the received document data.

Cancel the current print job and

resend the document data without

“Collate Copies” or “Collate”

selected for the printer driver

settings.

The

key blinks.

Received data is waiting for output.

Press the

key to output the data.

To delete data waiting for output,

press the

key.

“

”appears on the Print

Quantity Display and the machine

does not start.

When the machine is in use, the

power was turned off.

Press the

key.

Problem

Cause

Action

Troubleshooting

Troubleshooting Tips

93

The edges of printed copies are

smudged with ink.

Larger size of paper than the original

was placed on the Paper Feed Tray

at the time of the master-making

process.

Because a master was made

according to a larger size than the

original, the edges of the original

were processed as shadows. Set the

same size of paper as the original

and perform the master-making

operation again. Or attach tape as

described below to solve the

problem.

When printing thick paper such as

cards, corners of the paper

contacted and damaged the master.

Make another master and print with

the new master. Or pull out the Print

Cylinder(Drum) and attach

cellophane tape to the damaged

section on the master. However, if

attached with cellophane tape, a

master may not been properly sent

to the Master Disposal Box.

The back of printed copies is

smudged with ink.

The Pressure Roller has been

stained with ink.

Remove the Print Cylinder(Drum)

and clean the Pressure Roller.

)

p.78

If the print position is outside the

print paper, this may cause the

Pressure Roller to be stained with

ink.

Be careful when changing the size of

print paper or shifting the print

position.

Printed images are faint.

Printed texts are blurred.

If the machine is not used for an

extended period of time, ink on the

surface of the Print Cylinder(Drum)

may dry. This results in faint or

blurred printing just after printing is

started.

Press the

key and make several

copies before making copies to be

actually used. Or use the Idling

function.

)

p.53

Faint originals result in faint images. Increase the scanning level and

perform the master-making

operation again.

)

p.37

For originals written with a pencil,

select the Pencil mode.

)

p.33

If the temperature is low (below 59

°

F

or 15

°

C) in a place where the

machine is installed or Ink Cartridges

are stored, ink does not flow

smoothly.

Use the machine after keeping it at

room temperature for a while.

)

p.12

The Ink Saving mode has been set.

With the Ink Saving mode selected,

the ink on printed copies is fainter

than usual.

Problem

Cause

Action

Riso Kagaku Technical Training Center Version

Содержание RZ200AW

Страница 1: ...Riso Kagaku Technical Training Center Version...

Страница 2: ...MEMO Riso Kagaku Technical Training Center Version...

Страница 111: ...MEMO Riso Kagaku Technical Training Center Version...

Страница 112: ...Riso Kagaku Technical Training Center Version...