Check & Error Display

80

Troubleshooting

Check & Error Display

When an error occurs on the machine or when consumables or other sections are not yet ready, the Check & Error

Display shows error locations and numbers indicating error types. For some errors, error numbers are shown on the

Error Number Display (Print Quantity Display).

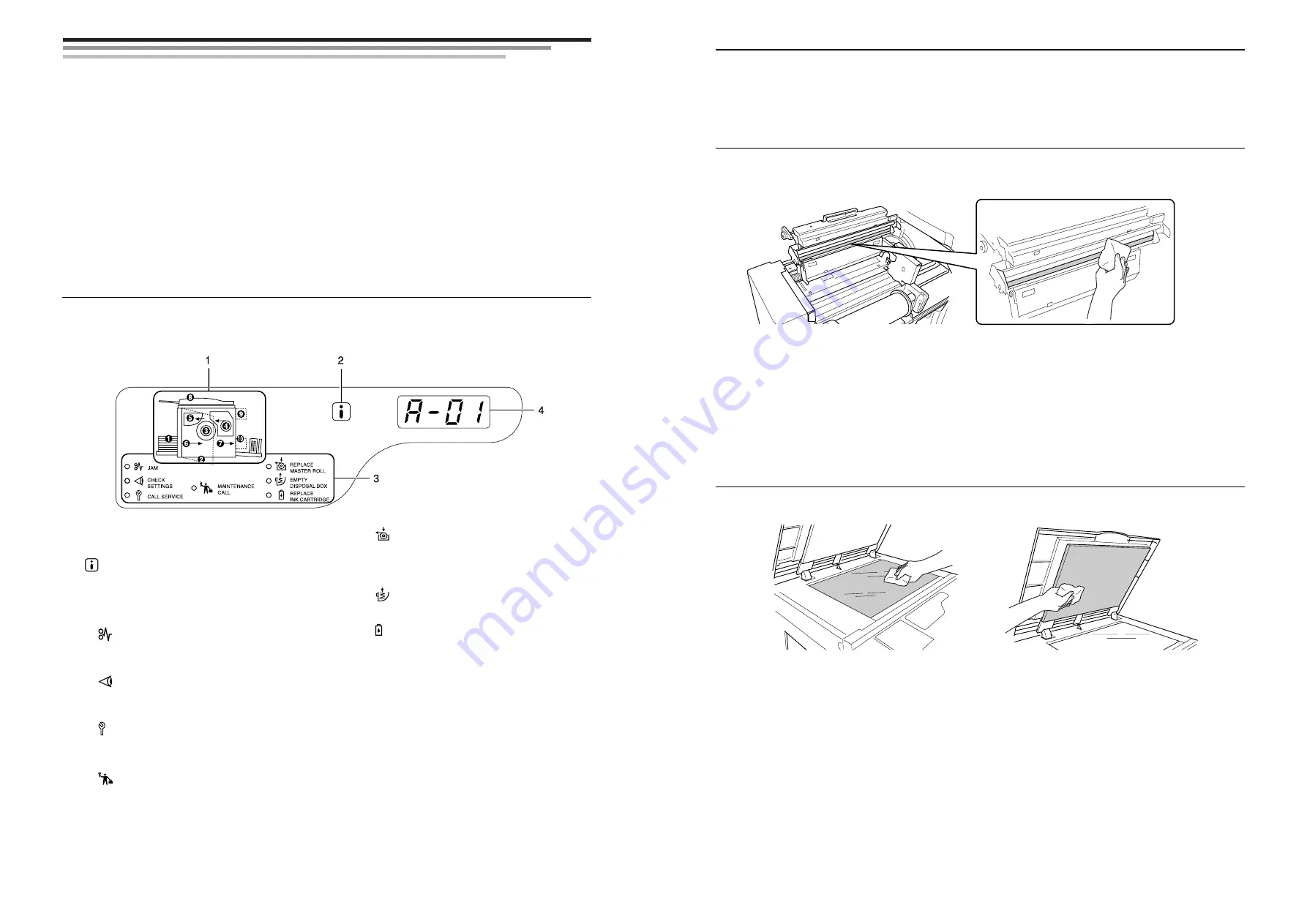

Checking with the Check & Error Display

Besides indicators that show error types, numbers that show error locations light.

Check the display and take an appropriate procedure according to the methods described on the subsequent pages.

1)

Error Location Indicator

Numbers corresponding to error locations light.

2)

indicator

Lights when the function is in use.

)

p.88

3)

Error Type Indicator

z

(Jam) Indicator

Lights when paper jams occur inside the

machine or ADF unit (option).

z

(Check Settings) Indicator

Lights when the Print Cylinder(Drum), paper, or

other items have not yet set up.

z

(Call Service) Indicator

Lights when such an error occurs that needs

advices or supports from service personnel.

z

(Maintenance Call) Indicator

Lights when the time for periodic inspection

comes.

z

(Replace Master Roll) Indicator

Blinks when the remaining master quantity is

small and lights up when the entire master is

consumed.

z

(Empty Disposal Box) Indicator

Lights when the Master Disposal Box is full.

z

(Replace Ink Cartridge) Indicator

Blinks when the remaining ink quantity is small

and lights up when the entire ink is consumed.

4)

Error Number Display

Error numbers appear and blinks on the Print

Quantity Display.

Error contents are shown with alphabetical charac-

ters (single digit) and numeric characters (two digits).

Cleaning

Cleaning

77

Cleaning

Thermal Print Head

Clean the Thermal Print Head each time you replace the Master Roll. Open the Master Making Unit Cover, and then

gently wipe the Thermal Print Head in the back of the unit several times with a soft cloth or tissue.

B

Caution:

• Since the Thermal Print Head is very delicate, avoid shocks or scratches with a hard object.

• Since Thermal Print Head is susceptible to (damage by) static electricity, please be sure to remove the static elec-

tricity charged in the body before cleaning.

Note:

• For more effective cleaning, dampen a soft cloth or tissue with a small amount of alcohol before wiping the Thermal

Print Head.

Stage Glass and Stage Cover

If the Stage Glass and/or Stage Cover is stained, gently wipe them with a soft cloth or tissue.

B

Caution:

• Since the Stage Glass is very delicate, avoid shocks or scratches with a hard object.

Riso Kagaku Technical Training Center Version

Содержание RZ200AW

Страница 1: ...Riso Kagaku Technical Training Center Version...

Страница 2: ...MEMO Riso Kagaku Technical Training Center Version...

Страница 111: ...MEMO Riso Kagaku Technical Training Center Version...

Страница 112: ...Riso Kagaku Technical Training Center Version...