Troubleshooting

Check & Error Display

88

When the indicator is off and “H” is shown on the Print Quantity Display.

In order to assure optimum printing, the machine acquires information from the consumables.

If any reasons prevent the machine from acquiring the information, “H” is shown on the Print Quantity Display.

Enter an appropriate parameter.

Entering an inappropriate parameter does not affect usual operations but may result in bad print quality.

The table shows the “H” numbers to be shown on the Print Quantity Display and the selectable parameters.

: For RZ2XX, unavailable

Note:

• When the

indicator is off, this indicates that the machine has failed to acquire information from the consum-

ables. If the machine fails to acquire information when consumables are replaced, you need to enter parameters

for shown H No’s. in order to supplement necessary information. If you perform the following operations after enter-

ing H No’s., the information disappears and thus you need to enter H No’s. again.

– After the power switch is set to

(OFF), the switch is set to

(ON) again

– After the machine is placed into the Sleep status, the

key is pressed

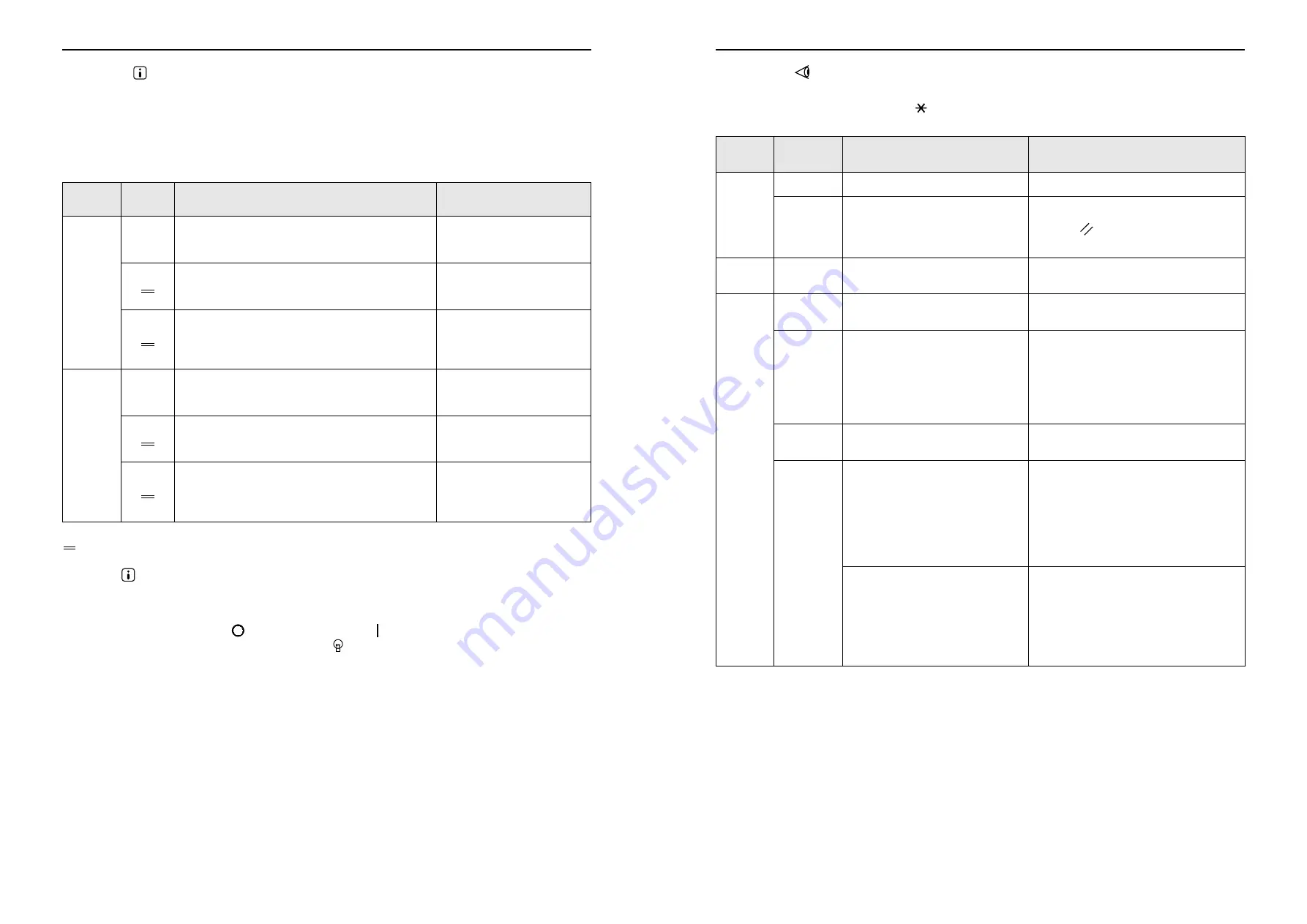

Location

No.

H No.

Description

Parameter

3

H1

Ink color setting

Select the same color as the currently used for Print

Cylinder(Drum).

1: black 2: color

H2

Print density fine adjustment (ink)

Perform fine adjustment to optimize the print density

depending on the ink.

1 (light) - 5 (dark)

H3

Sample copy density adjustment (ink)

Perform adjustment for print density for test printing

depending on the ink.

This adjustment is independent of H2.

1 (light) - 5 (dark)

4

H4

Master-making density setting

Set the reference density for the master-making

process.

1 (light) - 10 (dark)

H5

Print density fine adjustment (master)

Perform fine adjustment to optimize the print density

depending on the master.

1 (light) - 5 (dark)

H6

Sample copy density adjustment (master)

Perform adjustment for the print density for sample

copy depending on the master.

This adjustment is independent of H5.

1 (light) - 5 (dark)

Troubleshooting

Check & Error Display

85

When the indicator blinks

Check error locations and error numbers (Error Number Display) and take the following procedures.

If an error number is not shown, press the

[

]

key.

Location

No.

Error No.

Cause

Action

1

c-04

The tray has run out of paper.

Place paper on the Paper Feed Tray.

F-03

Custom-size paper has been placed

on the Paper Feed Tray at the time of

2-Up printing.

Custom-size paper does not allow 2-Up

printing.

Press the

key and then place regular-

sized paper.

2

d-11

The Front Cover is open or has not

been completely closed.

Close the Front Cover completely.

3

d-01

The Print Cylinder(Drum) has not been

set or has not been correctly set.

Set the Print Cylinder(Drum) correctly.

)

p.73

d-02

An inappropriate Print Cylinder(Drum)

has been set.

Set an appropriate Print Cylinder(Drum).

)

p.73

Important!:

• Use a Print Cylinder(Drum) specific to the

machine. Set other cylinders(drums) can

result in malfunction or any other troubles.

d-03

The Ink Cartridge has not been set or

has not been correctly set.

Set an Ink Cartridge correctly.

)

p.66

d-04

An inappropriate Ink Cartridge has

been set.

Set an Ink Cartridge specific to the machine.

)

p.66

Important!:

• Use an Ink Cartridge specific to the

machine.

Using other Ink Cartridges can result in

malfunction or any other troubles.

The label on the Ink Cartridge outlet

surface has come off or surface is with

dirt.

The label on the Ink Cartridge outlet surface

contains information needed for printing. If the

machine cannot read the information, it does

not operate.

Set an Ink Cartridge that is specific to the

machine and that is with label attachment and

free from dirt.

Riso Kagaku Technical Training Center Version

Содержание RZ200AW

Страница 1: ...Riso Kagaku Technical Training Center Version...

Страница 2: ...MEMO Riso Kagaku Technical Training Center Version...

Страница 111: ...MEMO Riso Kagaku Technical Training Center Version...

Страница 112: ...Riso Kagaku Technical Training Center Version...