Publication No. 5106227

12

MAX0041B

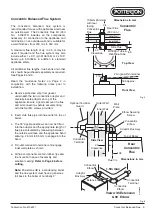

135˚

Bend

Ø60

Once the Terminal is

fitted the Head MUST

be pivoted to the

horizontal position

500

74

184

500

Flue

Air

Extension

Mini Terminal (sited in loft)

Support Bracket

Support

Bracket

Roof Tiles

Air Pipe

Flue Pipe

Flue Duct

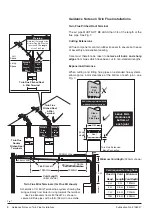

1.5m min

to

12m max

135˚

Bend

Warning

Note that the length

of the Air Inlet Pipe

MUST not be less

than

0.75 x length

of the Flue Pipe

Pitched Roof Terminal

(25˚- 45˚)

600 mm

min

apart

2 Pitched Roof Terminals

can be used

Pitched Roof

Terminal

(135˚ elbow fitted)

Twin Flue with Pitched Roof Terminal

Used in conjunction with the standard 60 mm diameter

twin pipe flue system, the Powermax Pitched Roof

Terminal (Part No. 5106164) provides an unobtrusive

alternative where horizontal mini terminals are not

practical. This terminal is supplied with a 0.5 m x 0.5 m

universal lead slate; thus it is suitable for use with tiles

and slate roofs with pitch angles of 25° to 45° (above

the horizontal).

The Pitched Roof Terminal must be ordered separately.

It is recommend that, where space and visual

considerations permit, a second similar terminal should

be used for the air supply, especially when the roof

pitch is less than 30°. As an alternative, combustion air

can be taken from a fully ventilated, unoccupied, roof

space providing the minimum free area of the vents is

no less than 234 cm2. Additional requirements are that

the air inlet pipe must not be less than 0.75 x length of

the flue pipe and the intake must be at least 300 mm

above the highest level of the ceiling insulation.

The Pipework Kit (Part No. 5106259) for the Pitched

Roof Terminal is based on a nominal 4.5 m of twin flue.

This allows, for example, up to 5 m of flue pipe between

boiler and flue terminal; plus up to 4 m of air pipe

between boiler and air terminal. The flue pipe must not

exceed 12 m; in which case the air pipe must not be

less than 9 m. The minimum length of flue pipe is 1.5 m

and the overall length is also governed by the number

of bends used - see calculation method on Page 15.

The components supplied with this kit are intended for

a typical application requiring 4.0 m to 4.5 m of air inlet

pipe with 2 bends plus 4.5 m to 5.0 m of flue pipe with

2 bends - See Fig. 16. Other configurations may be

used but a ‘horizontal’ run in the flue pipe should not

exceed 2 m and must not be allowed to dip, i.e. fall

below the horizontal and must always rise towards the

terminal. Any flue pipe accessible to occupiers of the

dwelling must be covered with protective ducts.

Fixing Pitched Roof Flashing

1. Place terminal flashing in position ensuring the

upwards edge of lead flashing correctly underlaps

the previous course.

Note:

Additional sarking may

be required - see recommendation in BRE Defect

Action Sheet 10 - November 1982 - Pitched Roof

Sarking Felt Underlay Watertightness.

2. Fix any secondary batten needed to support

terminal and reinforce any previously cut battens.

3. Cut slates or tiles to achieve the 290 mm vertical x

220 mm horizontal opening for the upstand of the

terminal. Re-tile roof and dress lead flashing over

bottom course.

4. Fix support bracket so as to secure the flue pipe

near the terminal.

Fig. 15

Fig. 16

Maximum & Minimum Lengths of Air/Flue Pipes