Publication No. 5106226

43

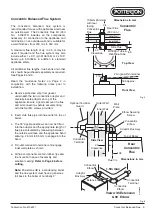

Gas/Air Valve Setup Procedure

7. After 2 minutes, the boiler control will

return to normal operation. Maintain full

central heating demand (or if this is not

possible, draw hot water from a bath tap) to

cause the fan speed to increase to

maximum.

8. Check CO2 content of the flue gas

indicated by combustion analyser.

At maximum fan speed, this should be 9.0

to 9.2% CO2.

For values other than this, use throttle

adjustment screw to obtain correct

setting.

Note:

Turning screw clockwise reduces

CO2; anti-clockwise increases CO2.

Ensure fan does not modulate by

maintaining a CH or DHW demand during

the above sequence.

As a double check, the expected CO

content should be in the range of 65 to 85

ppm when CO2 is 9.1%.

Check that gas rate is approximately 2.55

m3/hr.

9. Replace dust cover,

re-instate air signal

tube between air duct and gas valve

,

checking that tube has not physically

deteriorated or been damaged e.g. cracked.

Carefully replace special sealing screw in

flue gas test point.