Publication No. 5106226

16

MAX0021B

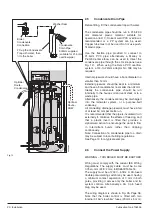

Outline of base plate

Outline of front panels

Double arrows are from rear of boiler

70

43

119

122

35

60

54

512

514

536

560

572

544

507

DHW

TPRV

Discharge

Cold

Feed

Gas

Condensate

39

567

Dimensions are approximate

All pipes are 22mm

C/H Flow

Alternate

C/H Flow or

Condensate

Outline of insulation

46

C/H Return

550 Overall

600 o

v

er

all

Installation Requirements

2. Installation

2.1

Install the boiler

Before starting an installation, check that the correct flue

kit and correct capacity cylinder have been supplied.

Important: When soldering plumbing fittings, do not

allow flame from blowtorch to come into contact with

the insulating foam or other non-metallic parts.

Guidance on where to locate the boiler is given in Sections

1.3 and 1.5.

In some instances it will be advantageous

to pre-plumb pipework or to pre-fix terminal, air/flue

pipes and duct

.

1. Remove top and front panels (see Page 3) and

carefully set aside.

2. Determine boiler final position. The cutaway in the

cylinder base allows pipework to be brought up from

below floor level. Use the dimensions below or the

template on the reverse of the Installation Guide to pre-

drill any holes. Pipes must not obstruct service access

to the immersion heater (if fitted) or to the condensate

trap.

3. Move boiler into position. The need to move as Top and

Bottom sections or as a complete assembly will

depend on the individual installation. The Top has 4

downward facing dowel pins which provide accurate

location on to the cylinder. Take care to avoid trapping

hands and fingers during assembly.

4.

Apply sealant to cone faces

of both 22mm Union

Nuts (see Fig. 10). Remove cardboard pipework

support. Attach the 15mm x 90° branch pipe joining the

two relief valves/tundish.

5. Release DHW temperature sensor and un-roll cable.

Route cable behind cylinder pipes and push sensor

fully home (approx. 310mm - 12”) into the pocket in the

cylinder.

6. Remove small knock-outs as required either side of

casing for plumbing access. The handholds in the side

panels can also be used. Further access holes allow

the condensate to be routed via the LH panel and the

DHW to be plumbed via the RH panel.

2.2

Connect the Flue System

1. Unless already fitted, install the flue system as shown

in the Installation Instructions supplied with the flue kit.

2.3

Connect the Gas Supply

1. Ensure that the gas supply is isolated.

2. The gas connection to the boiler is 22 mm.

Refer to Section 1.1 for information on the required gas

supply.

Do not turn the gas supply on at this stage.

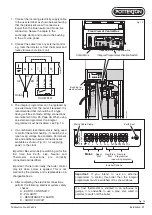

Fig. 9

MAX0023C

22mm Gas

Connection

-

+

PROG

SEL

PROG

SEL

-

C.H. ADVANCE

H.W. TEMP

RESET

BURNER

LOCK OUT

MAINS ON

POWER

+

RWC

This Appliance

Must Be Ear

thed

N

L

N

F HW HW CH CH

T

T

R

L

L

R

R

L

R

2

L

2

Gas

Cock

(0pen)

Fig. 8