Publication No. 5106226

35

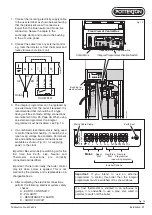

Powermax

-

+

SEL

SEL

-

+

MAIN

S ON

POW

ER

CH

HW

PRO

G

PROG

C.H. ADVA

NCE

H.W. TE

MP

RESE

T

BUR

NER

LOC

K OU

T

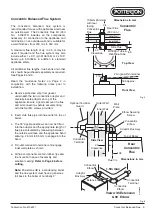

Side View

of

Heat

Exchanger

Heat

Exchanger

Heat Exchanger

bottom of case

To remove

Heat Exchanger

swing bottom forward

Condensate Pipe

(not supplied

with Heat Exchanger)

Condensate

Transfer

Pipe

Condensate Trap

Flue

Diecasting

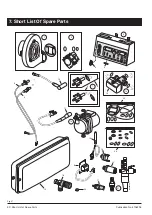

'O' Rings/Seals Kit

Gas (Part No. 5106295)

'O' Rings/Seals Kit

Water (Part No. 5106296)

Remove bottom

Clip from the Saddle

Burner

Assembly

removed

Saddle

Disconnect Flow

& Return Pipes

Flow &

Return

Pipe

Securing

Clips

Saddle

Flue

Diecasting

Flue Seal

Grommet

Disconnect

HE

from RH

Support

Bracket

(which is

part of case)

Disconnect

H. Exchanger

from LH

Support Brackets

MAX0025B

4.12

Heat Exchanger

Note:

Replacing the heat exchanger

involves disconnecting the appliance from

the flue and air pipes. It is essential that the

flue system is fully reinstated and tested so

we recommend that the appropriate

replacement flue pipe and fittings be

obtained before starting this work. The slip

fitting Part No.5106807 will be helpful in

reinstating extended twin pipe flue systems.

Re-assemble all parts in reverse order.

1. Perform 4.1 General Access.

2. Check that the boiler primary system is

isolated from the mains water supply.

Release pressure from the primary

system and drain down.

3. Remove expansion vessel, pump, gas

valve, fan/venturi, diverter valve and heat

exchanger door (complete with burner) all

as detailed in previous sections. Remove

flow and return pipework from the push-fit

connections on RH manifold of heat

exchanger. Retain securing clips for re-

use.

4. Disengage air inlet duct from elbow on top

RH side of boiler and set aside. Unscrew

3 c/sunk screws and remove air inlet

elbow.

5. Disconnect wiring from temperature

sensors and overheat thermostat.

Carefully remove HT lead from spark

generator.

6. Disconnect flue pipe. Remove “hidden”

M6 nut - see Fig. 24, at RH rear of heat

exchanger and remove two M6 flanged

set screws securing the LH suspension

bracket. Support weight of heat

exchanger before removing the clip and

saddle beneath.

7. Lift heat exchanger vertically about 19mm

(3/4”) to disengage condensate spigot

from its socket in the base panel; then tilt

forward from the bottom to remove.

Fig. 24

Replacement of Parts