Publication No. 5106226

26

Commissioning

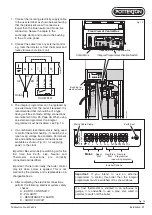

3. Press the DHW select button to switch hot water on

(green neon stays on).

4. Press reset button to scroll through LH window until

display shows “p 1.5” to check that system pressure

is between 0.9 to 2.5 bar. Adjust as necessary. The

fan starts to rotate after a slight delay and a few

seconds later the automatic ignition sequence will

be initiated. The green burner neon will indicate when

the burner lights.

5. If the burner fails to light, the ignition sequence will

be automatically repeated until either the burner

lights or a safety LOCK-OUT condition is signalled by

the red neon. If red neon shows, press the reset

button indicated.

6. With the boiler operating check the flame is stable.

Note:

After first filling with cold water some noise

may occur within the combustion chamber as the

flame settles on the burner. This is normal and will

soon disappear.

7. Record the “working” inlet gas pressure at inlet

pressure test nipple in “Benchmark” logbook.

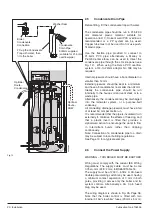

8. Check gas valve differential (offset) - See Fig. 28,

Page 42

Note:

This valve has been factory pre-set and

adjustment is not normally required.

a. Loosen screw in outlet pressure test point and

connect to “+” (positive) side of differential micro-

manometer.

b. Tee the “-” (negative) side of the micro-manomter

into the air signal tube as shown in Fig. 28.

c. Switch on central heating using CH select button

and switch off hot water. The boiler will re-start in

CH mode after approx. 1 minute.

d. After boiler has been operating in CH mode for

several minutes, simultaneously press the “+” and

“STEP” buttons and hold down for 5 to 6 seconds.

After a minute the boiler will be operating at low

input and the differential can be checked.

e. Ensure micro-manometer has been zeroed (if in

doubt re-zero).

f. Check the differential reading. This should be zero

to minus 5 Pa (0.00 to - 0.05 mbar). If adjustment

is required refer to Page 42.

g. Disconnect micro-manometer,

re-instate signal

tube between air duct and gas valve

, and test

for gas soundness.

9. Turn boiler off, remove gauge, tighten test screws

and test for gas soundness.

Central Heating System

1. Press button to select heating (indicated by stable

green neon).

2. Check that any connected room thermostat is calling

for heat.

3. Note that the 3-way diverter valve does not allow

circulation to the CH circuit until the storage cylinder

contents have reached the selected temperature.

After filling with cold water, this will normally take

between 20 to 25 minutes.

4. With flow to the CH circuit, bleed every radiator and

the pipework high points until all air or air/water mix

has been removed.

5. Vent the boiler again if necessary - note that the

burner control goes to safety shut-down if the

system pressure drops below 0.5 bar.

6. Wait until the central heating circuit has reached its

normal temperature of approx. 80 °C before

balancing the radiators in the usual way to achieve

a temperature drop of 10 °C.

7. Allow system to reach full temperature (all radiators

at working temp.) and note “hot system” pressure.

Switch boiler off, drain and flush the system.

8. Refill (using a suitable inhibitor) and remove all air

and air/water mix. Check the relief valve is not

“letting” by observing pipe outlet for several minutes.

(“Letting” is usually due to debris on valve seat.

Snapping the valve open-shut a few times will

normally cure this).

9. Check that the system final pressure equals “hot

system” pressure as noted in 7. above. Adjust if

necessary.

10.Set the room thermostat or programmer according

to the manufacturer’s instructions.

11.Disconnect filling loop flexible hose and leave in a

secure place for householder.

Domestic Hot Water System

1. With the cylinder fully heated, check DHW output

temperature is approximately 45 to 65 °C (as

selected) using nearest tap and a flow rate of

approximately 5 l/min. Record inlet and outlet

temperatures in “Benchmark” log book.

2. Measure hot water flow rate at bath rap (fully open)

and record in “Benchmark” log book.

3. Refit outer covers in reverse order.

3.2 Hand Over to the User

1. Explain the boiler controls

2. Give guidance if the system is to be shut down for

long periods when freezing is possible

3. Advise the User that for continued efficient and safe

operation of the boiler it is important that adequate

servicing is carried out.

4. Explain how to re-start boiler if red neon indicates

lockout.

5. Hand over the User’s Instructions.

6. Carefully read and complete all sections of the

“Benchmark” Installation, Commissioning and

Service Record Log Book that are relevant to the

appliance and installation. The details of the Log

Book will be required in the event of any warranty

work. The Log Book must be handed to the user for

safe keeping and each subsequent regular service

visit recorded. For IE, it is necessary to complete a

“Declaration of Conformity” to indicate compliance to

I.S. 813. An example of this is given in I.S. 813

“Domestic Gas Installations”. This is in addition to the

“Benchmark” Log Book.