ELECTRICAL

10.14

OFF SEASON STORAGE

To prevent battery damage during extended periods of non-use, the following basic battery maintenance items

must be performed:

S

Remove the battery from the machine and wash the case and battery tray with a mild solution of baking

soda and water. Rinse with lots of fresh water after cleaning. NOTE: Do not get any of the baking

soda into the battery or the acid will be neutralized.

S

Using a wire brush or knife, remove any corrosion from the cables and terminals.

S

Make sure that the electrolyte is at the proper level. Add distilled water if necessary.

S

Charge at a rate no greater than 1/10 of the battery’s amp/hr capacity until the electrolyte’s specific

gravity reaches 1.270 or greater.

S

Store the battery either in the machine with the cables disconnected, or put it on a piece of wood and

store in a cool place. NOTE: Stored batteries lose their charge at the rate of 1% per day. They

should be recharged to a full charge every 30 to 60 days during a non-use period. If the battery is

stored during the winter months the electrolyte will freeze at a higher temperature as the battery dis-

charges. The chart at below indicates freezing points by specific gravity.

CHARGING PROCEDURE

Charge the battery with a charger no larger than 1/10 of the battery’s amp/hr rating for as many hours as needed

to raise the specific gravity to 1.270 or greater.

Electrolyte Freezing Points

Specific Gravity

of Electrolyte

Freezing

Point

1.265

-75

°

F

1.225

-35

°

F

1.200

-17

°

F

1.150

+5

°

F

1.100

+18

°

F

1.050

+27

°

F

1.

Install battery in vehicle with positive terminal toward the front. Coat threads of battery bolt with a corrosion

resistant Nyogel

t

grease.

WARNING

To avoid the possibility of explosion, connect positive (red) cable first and negative (black) cable last.

2.

Connect battery cables.

3.

After connecting the battery cables, install the cover on the battery and attach the hold down strap.

4.

Install clear battery vent tube from vehicle to battery vent. WARNING: Vent tube must be free from

obstructions and kinks and securely installed. If not, battery gases could accumulate and cause an explosion.

Vent should be routed away from frame and body to prevent contact with electrolyte. Avoid skin contact with

battery electrolyte, severe burns could result. If electrolyte contacts the vehicle frame, corrosion will occur.

5.

Route cables so they are tucked away in front and behind battery.

Dielectric Grease

PN 2871329 (Nyogel)

Содержание Sportsman 400

Страница 5: ...SPORTSMAN 400 A01CH42AB SPORTSMAN 400 A01CH42AA GENERAL INFORMATION 1 3 MODEL COLOR IDENTIFICATION ...

Страница 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Страница 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Страница 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Страница 94: ...ENGINE 3 25 CYLINDER HEAD EXPLODED VIEW 1 Remove the two 6mm flange bolts A from cylinder head A ...

Страница 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Страница 325: ...BRAKES 9 22 FRONT BRAKE CALIPER EXPLODED VIEW Pads Caliper Mount Piston Pin Boot Square O Rings Adjuster Screw ...

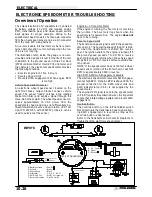

Страница 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Страница 372: ...ELECTRICAL 10 38 NOTES ...

Страница 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Страница 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Страница 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...