Troubleshooting

45

▐

13 Troubleshooting

During motor operation, the motor or driver may fail to function properly due to an improper setting or wiring. When

the motor cannot be operated correctly, refer to the contents provided in this section and take appropriate action. If

the problem persists, contact your nearest Oriental Motor sales office.

This chapter describes problems that may occur during operation in addition to the initial settings.

Refer to the

AZ

Series Function Edition for these contents.

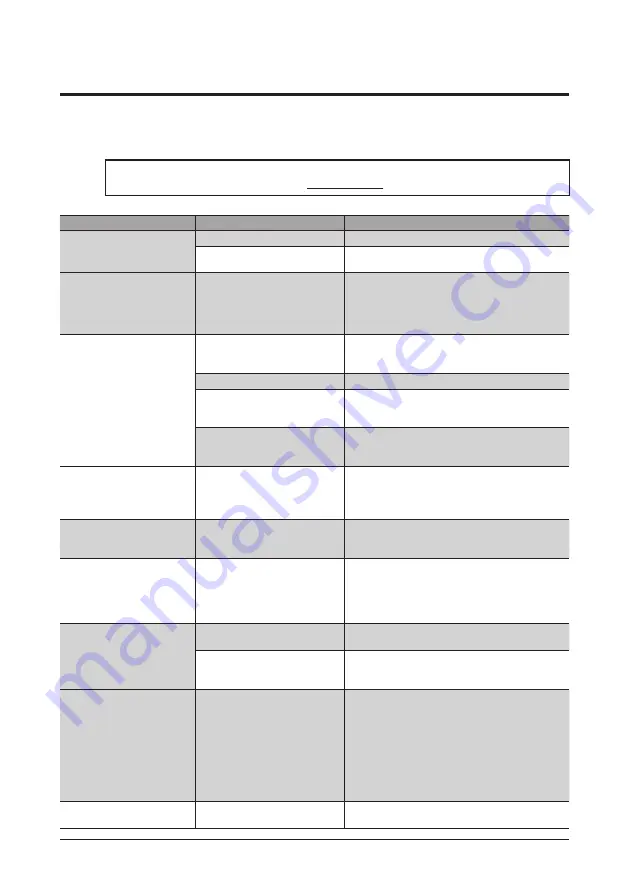

Phenomenon

Possible cause

Remedial action

The motor is not excited.

The motor output shaft can

be moved by hand.

Connection error in the motor.

Check the connections between the driver and motor.

The FREE input is turned ON.

Turn the FREE input OFF.

There is holding torque even if

motor excitation is turned OFF.

Eff ect of dynamic brake.

If motor excitation is turned OFF by C-ON input or

STOP input, the holding torque will be generated

larger than when the power is shut off (dynamic

brake). To release the dynamic brake, shut off the

power or turn the FREE input ON.

The motor does not operate.

An electromagnetic brake motor is

used and the electromagnetic

brake is in the holding state.

Check the connections between electromagnetic

brake and driver.

The STOP input is turned ON.

Turn the STOP input OFF.

The position (distance) is not set in

the operation data while

positioning operation.

Check the operation data.

The FWD-JOG input and RVS-JOG

input are turned ON simultaneously

in the JOG operation.

After turning both the FWD-JOG input and RVS-JOG

input OFF, turn either one of them ON.

The motor does not rotate

although the READY LED is lit.

(only for pulse-input type)

Signals are not connected

properly.

Multiple signals have been input

simultaneously.

Wire signals correctly.

Check if the signal line is disconnected.

Check if the wrong signal is input.

The motor rotates in the

direction opposite to the

specifi ed direction.

The "motor rotation direction"

parameter is set wrong.

Check the setting of the "motor rotation direction"

parameter.

The gear output shaft rotates in

the direction opposite to the

motor.

A gear that rotates in the direction

opposite to the motor shaft is used.

With

TS

geared motor, the gear output shaft rotates

in the direction opposite to the motor when the gear

ratio is 20 or 30.

With Harmonic geared motors, the gear output shaft

always rotates in the direction opposite to the motor.

Motor operation is unstable.

Connection error in the motor or

power supply.

Check the connections between the driver, motor and

power supply.

The base current rate setting is too

low.

Return the CURRENT switch to its initial setting and

check. If the current is too low, the motor torque will

also be too low and operation will be unstable.

Motor vibration is too great.

Load is too small.

Built-in controller type, pulse input type with RS-485

communication interface;

Lower the current using the "Base current"

parameter. Vibration will increase if the motor’s

output torque is too large for the load.

Pulse input type;

Lower the current using the CURRENT switch.

Vibration will increase if the motor’s output torque is

too large for the load.

The electromagnetic brake

does not release.

The power is not supplied to the

electromagnetic brake.

Check the connection of the electromagnetic brake.