39

INDUSTRY

Section 4

Installation

Special attention must be paid during lifting and

transport. Designate these operations exclusively to

personnel specialised and trained in machinery

handling procedures and able to choose and safely

use the most suitable lifting and transport means. No

liability is accepted for non-compliance with the

safety regulations in force in the country where the

blast chiller is installed.

WARNING!

Strictly follow the operations listed below in order to

correctly set up the blast chiller in designated work

area. The blast chiller has suitable packaging in order to

protect it from damage during transport. The packaging

may vary: cardboard box with wooden bottom, wooden

crate etc.

Unless otherwise stated, the purchaser or installer are

responsible for the following:

•

Preparation of the tools necessary for installation.

•

Preparation of auxiliary means and consumables.

We recommend keeping the packaging for the entire

warranty period. "La Nuovagel S.r.l." reserves the right to

accept equipment sent to the service centre or without

its original packaging.

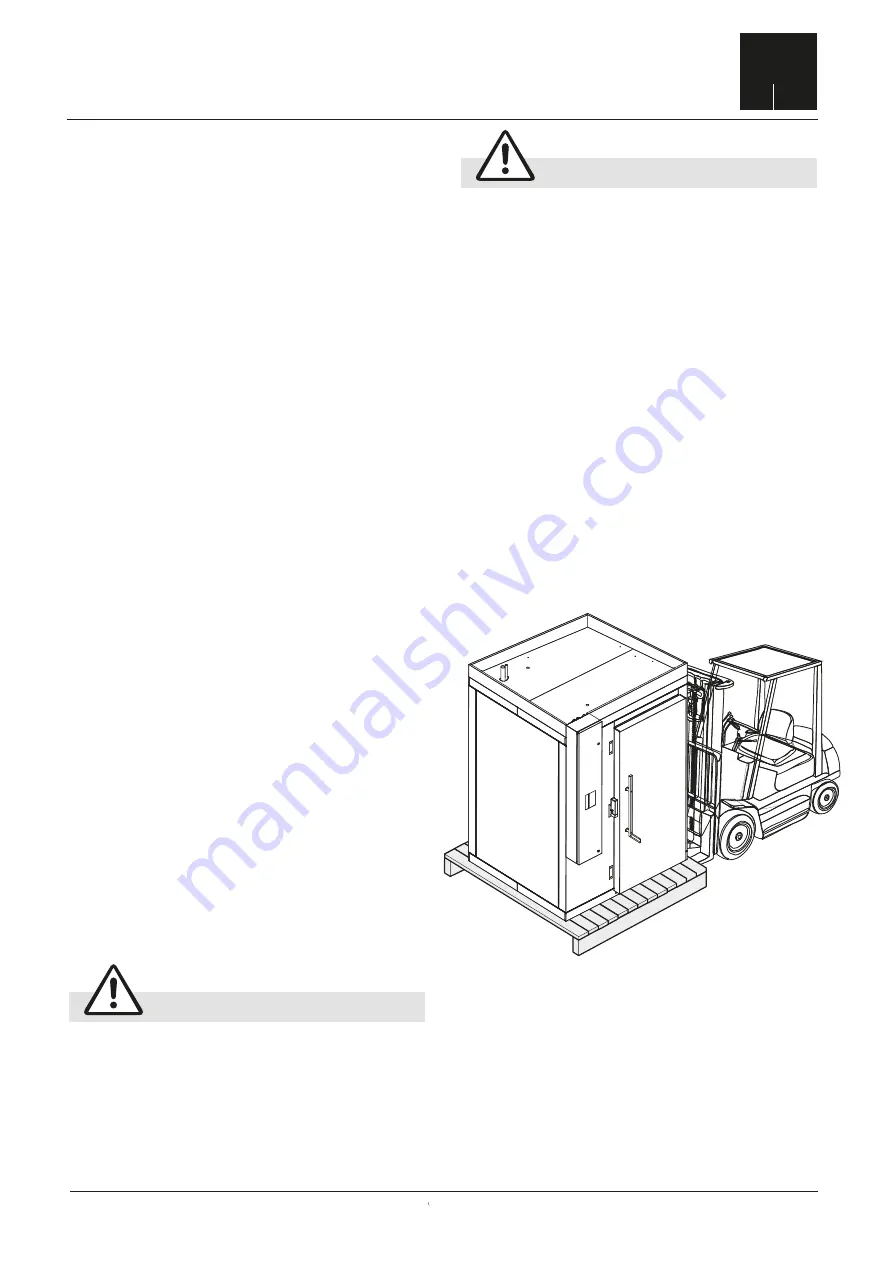

The operations of lifting, handling and positioning of the

blast chiller can be carried out with any suitable means

that guarantees effective and safe lifting and handling.

Handling operations, for example, can be carried out

with a pallet jack or forklift truck with suitable fork

length or with the aid of a crane in the case in which the

machine/ partly-completed machinery is set up for

such handling.

4.6

PRELIMINARY OPERATIONS

Do not stack multiple blast chillers on top of each other

unless they are packed in a crate or cage. It is recom-

mended that the machine/partly-completed machinery

be transported always and only in a vertical position to

prevent the oil present in the compressor from moving

inside the piping to other components (plate, compres-

sor valves) as well as to prevent the springs that support

the compressor motor, which can cause possible

damage to them during transport.

If the blast chiller is tilted for handling or transport, once

the vertical position is restored, wait at least 12 hours

before starting the machine; in this way it will allow the

oil to flow from the components towards the lower part

of the compressor.

4.6.1 TRANSPORT, UNLOADING

and UNPACKING

The temperature of the machine/partly-completed

machinery during transport must not exceed 55°C.

WARNING!