- 2 -

1. To ensure safe use

*Always observe the following items to ensure safe use of the industrial sewing machine drive unit (motor and control box).

1.1 Before starting

Read all instruction manuals thoroughly before starting use of this drive unit, and follow the technical manuals. Also read the instruction

manuals for the installed sewing machine.

1.2 Application and purpose

This drive unit is designed to drive a sewing machine and must not be used for other applications or purposes. Do not use this drive unit until

it can be confirmed that safety measures for the installed sewing machine have been taken.

1.3 Work environment

Use this drive unit in dry and well-kept clean locations, e.g. in the clothing industry, and which process dry sewing material.

Avoid using this control unit in the following types of environments.

(1) Power voltage

- Place where voltage fluctuation exceeds ±10% of the rated voltage.

- Place where the specified power capacity cannot be secured. (Refer to page 8)

(2) Electromagnetic

noise

- Place where strong electric or magnetic fields are generated such as near a large-output high frequency

oscillator or high frequency welding machine.

(3) Temperature

and humidity

- Place where atmospheric temperature is 35 degree or higher and 5 degree or lower.

- Place subject to direct sunlight or outdoors.

- Near a heat source such as a heater.

- Place where relative humidity is 45% or less and 85% or more, or where dew condensation occurs.

(4) Atmosphere

- Atmosphere with dust or corrosive gases.

- Atmosphere with combustible gases or explosive atmosphere.

(5) Altitude

- Place where altitudes exceeds 1,000m above mean sea level.

(6) Storage

- Place where storage temperature is 55

℃

or higher and -25

℃

or lower.

(7) Vibration

- If excessive vibration occurs when the control box is installed on the sewing machine, install it separately.

2. Installation

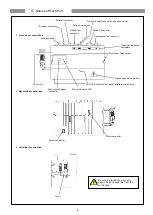

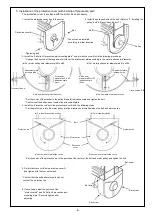

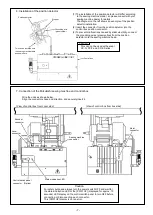

2.1 Motor and control box

- Correctly install according to the attached technical manuals.

2.2 Accessories

- Always disconnect this control unit from the main power supply when installing any accessories listed in the technical manual. (Turn the

main switch OFF, and remove the plug from the outlet (power supply line).)

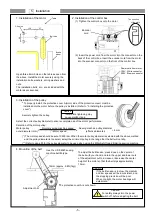

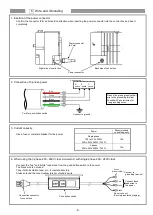

2.3 Cable

(1) Arrange the connection cable so that excessive force is not applied during use, and do not excessively bend the cable.

(2) Cables near moving parts (e.g., pulley) must be wired at a minimum distance of 25mm.

(3) Confirm that the power voltage of the power cable for supplying to the control box meets the specifications on the motor and control box

rating nameplates before connecting it to the power line. Connect it to the designated places to supply the power. Perform this step with the

power switch turned OFF.

2.4 Grounding

- Correctly connect the power cable grounding to the power supply grounding.

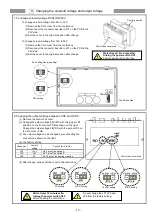

2.5 Accompanying appliances and accessories

- Electric accompanying appliances and accessories must be connected to the place listed in this manual.

2.6 Removal

(1) Turn the power switch OFF and remove the plug from the outlet (power supply line) before removing the motor or control box.

(2) Do not pull on the cord when removing the plug. Always hold the plug itself.

(3) There is a high voltage applied inside the control box, so always

wait at least 10 minutes after running the power switch OFF

and

remove the plug from the outlet (power supply line) before opening the control box panel.

3. Maintenance, inspection and repairs

- Follow the technical manuals for maintenance and inspection of this control unit.

- Repairs and maintenance must be done and approved by specially trained personnel.

- Do not run this control with the ventilation openings of the motor's dust-proof filter blocked or clogged with dust, loose cloth, etc.

- Always turn the power switch OFF and remove the plug from the outlet (power supply line) before replacing the sewing machine needle or

bobbin, etc.

- Always use original replacement parts for repairs or maintenance.

4. Other safety measures

- Keep fingers away from all moving machine parts (especially near sewing machine needle, etc.).

- Do not drop this control unit.

- Do not operate this product without parts such as the protective cover or protective devices such as the safety breaker.

- The servomotor surface may reach high temperatures depending on the operation conditions and loads. Do not touch directly.

- If any damage is observed on this control unit, if the drive does not run properly or if operator is uncertain about operation, do not operate the

drive unit. Operate the drive only after adjustments, repairs and approvals have been made by qualified personnel.

- The user must avoid making modifications or changes based on user's judgment.

- When system have to be stop in case of emergency, remove the power supply plug from the power supply line.

5. Hazard display, warning display

(1) This symbol indicates risk that may cause personal injury or risk to the machine

when mishandling of products.

(2) This symbol indicates electrical risks and warnings.

(3) This symbol indicates thermal risks and warnings.

- Always deliver this instruction manual to the end user.

- Save these technical manuals for future reference.

2 Safety Instructions