- 27 -

name

Function

No.

DN.

ON output delay time

0456

OO.

OO output function selection

0457

OOL.

OO output logic changeover

0458

OOT.

OO output forced OFF

0459

DO.

OO output delay time

0460

OP.

OP output function selection

0461

OPL.

OP output logic changeover

0462

OPT.

OP output forced OFF

0463

DP.

OP output delay time

0464

OQ.

OQ output function selection

0465

OQL.

OQ output logic changeover

0466

OQT.

OQ output forced OFF

0467

DQ.

OQ output delay time

0468

O.R.

OR output function selection

0469

O.RL.

OR output logic changeover

0470

O.RT.

OR output forced OFF

0471

DR.

OR output delay time

0472

PO.

Full wave output time for each output

0473

POD.

Output chopping duty except of FU output

0474

OTT.

Forced OFF timer setting function for each

output

0475

FCT.

Time setting for FUM operation mode

0476

A1.

Logic [AND] module input function selection

0477

A1L.

Logic [AND] module setting of Hi/Low logic

0478

A1A.

Logic [AND] module Alternate

0479

N1.

Logic [AND] module

output function selection

0480

N1L.

Logic [AND] module setting of Hi/Low logic

0481

N2.

Logic [AND] module

output function selection

0482

N2L.

Logic [AND] module setting of Hi/Low logic

0483

A2.

Logic [AND] module input function selection

0484

A2L.

Logic [AND] module setting of Hi/Low logic

0485

A2A.

Logic [AND] module Alternate

0486

N3.

Logic [AND] module

output function selection

0487

N3L.

Logic [AND] module setting of Hi/Low logic

0488

N4.

Logic [AND] module

output function selection

0489

N4L.

Logic [AND] module setting of Hi/Low logic

0490

A3.

Logic [AND] module input function selection

0491

A3L.

Logic [AND] module setting of Hi/Low logic

0492

A3A.

Logic [AND] module Alternate

0493

N5.

Logic [AND] module

output function selection

0494

N5L.

Logic [AND] module setting of Hi/Low logic

0495

N6.

Logic [AND] module

output function selection

0496

N6L.

Logic [AND] module setting of Hi/Low logic

0497

OR.

Logic [OR] module input function selection

0498

ORL.

Logic [OR] module setting of Hi/Low logic

0499

ORA.

Logic [OR] module Alternate

0500

R1.

Logic [OR] module output function selection

0501

R1L.

Logic [OR] module setting of Hi/Low logic

0502

R2.

Logic [OR] module output function selection

0503

R2L.

Logic [OR] module setting of Hi/Low logic

0504

CSP.

Variable speed command for digital input

0505

CSG.

Variable speed command for digital input

(Gray code)

0506

LB.

Thread r backstitch output

0507

T1C.

Virtual output OT1 forced OFF function

0508

T1T.

Forced OFF timer setting function for virtual

output OT1

0509

T2C.

Virtual output OT2 forced OFF function

0510

T2T.

Forced OFF timer setting function for virtual

output OT2

0511

T3C.

Virtual output OT3 forced OFF function

0512

T3T.

Forced OFF timer setting function for virtual

output OT3

0513

D11.

ON delay time setting function for virtual

output OT1

0514

D12.

OFF delay time setting function for virtual

output OT1

0515

D21.

ON delay time setting function for virtual

output OT2

0516

D22.

OFF delay time setting function for virtual

output OT2

0517

D31.

ON delay time setting function for virtual

output OT3

0518

name

Function

No.

D32.

OFF delay time setting function for virtual

output OT3

0519

CPK.

Feed pulse output (CP) cancel function

0520

CP.

Setting CP pulse amount

0521

CPC.

Prohibited angle of output CP pulse

0522

PSW.

Panel switch operation prohibit

0523

CKB.

O4, O5 output cancel during backtack term

0524

CPB.

CP output cancel during backtack term

0525

C.

Speed setting for the [SPC] output

0526

D.

Speed setting for the [SPD] output

0527

E.

Speed setting for the [SPE] output

0528

CNF.

F key function on control panel

0529

PDS.

Variable speed pedal changeover setting

0530

V2C.

Speed instruction VC2 cancellation

0531

name

Function

No.

D1.

Operation mode during tacking

0600

D2.

Operation mode during start tack completion

0601

CT.

Stop time at each corner during start and

backtacking

0602

BM.

Tack alignment

0603

BT1.

No. of stitch compensation for start tacking

alignment

0604

BT2.

No. of stitch compensation for start tacking

alignment

0605

BT3.

No. of stitch compensation for end tacking

alignment

0606

BT4.

No. of stitch compensation for end tacking

alignment

0607

BTP.

No. of tacking stitches (+) 15 stitches function

0608

BTO.

No. of tacking stitches addition stitches

function

0609

BTT.

Full heeling function immediately after start

tacking stop

0610

CSJ.

Not used.

0611

SPN.

The speed operation mode when both the

medium speed signal and S5V signal is ON

0612

BTM.

Set table types of tacking

0613

S7M.

Input signal S7 operation mode during preset

stitching

0614

S7U.

Manual backstitch ON timing 1

0615

S7D.

Manual backstitch ON timing 2

0616

7BD.

The OFF timing setting of output B when the

backstitching signal (S7) is OFF setting.

0617

BTN.

The maximum tacking stitches (maximum

stitches is 99 stitches)

0618

BCC.

No. of end tacking stitches during direct

heeling

0619

TLS.

Operation mode during thread trimmer

cancel signal [TL] setting

0620

BTS.

Input signal BTL quick pressing operation

0621

BS.

Input signal SB and EB quick pressing

operation

0622

BTD.

Operation when input signal BTL is ON

0623

BD.

Operation when input signal SB and EB

tacking OFF are set

0624

PNE.

End tacking cancel mode with input signal

PSU

0625

BZ.

The buzzer of control panel validity

0626

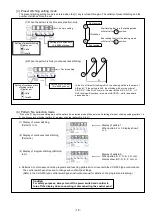

D

m

od

e

(

Fo

r

tacki

ng

set

ti

ng

m

od

e

):

[

↓]

+

[D

]

key

C

m

od

e

(

Fo

r

se

tt

ing

i

np

u

t/

ou

tpu

t

si

gn

al

t

o

f

un

ct

ion

):

[

↓]

+

[C

]

key

C

m

od

e

:

[

↓]

+

[C

]

key