5-6

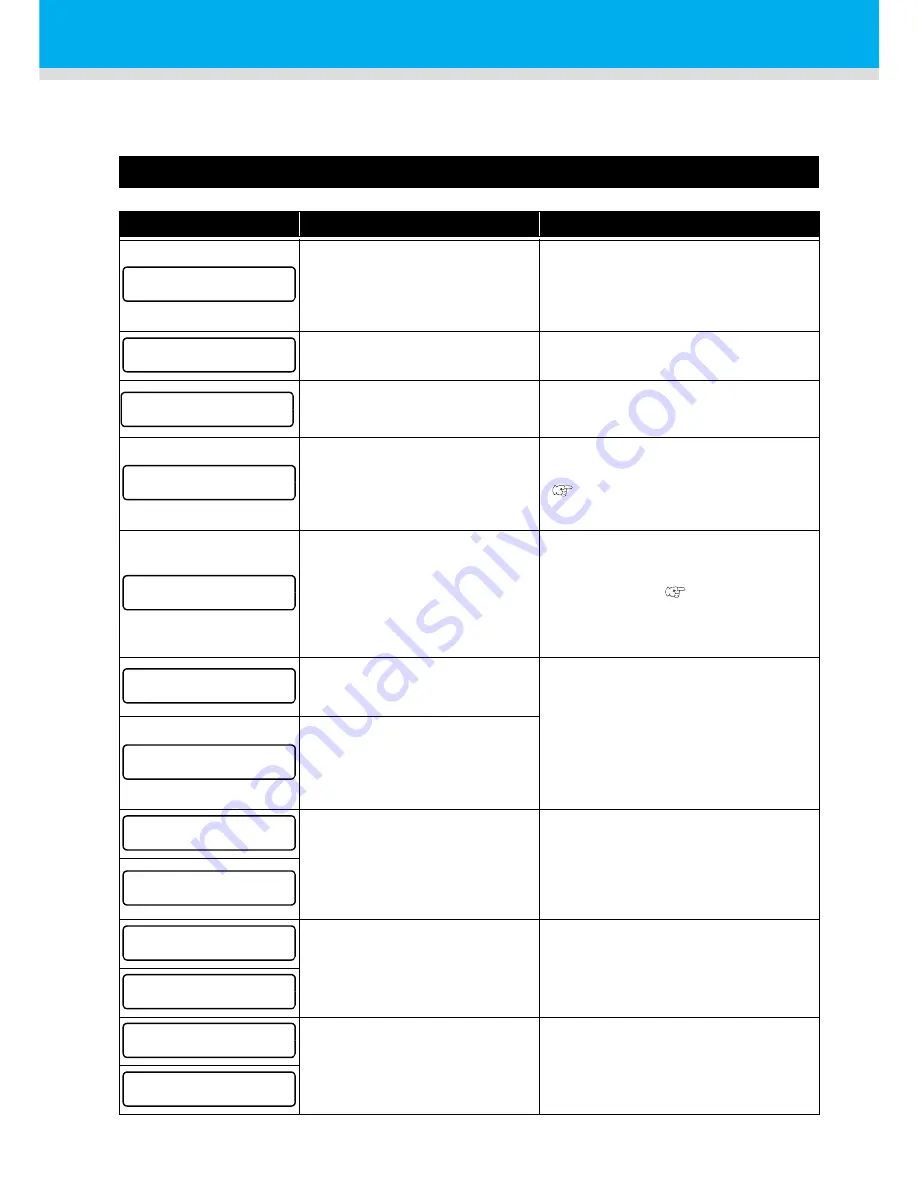

Warning / Error Messages

If some trouble occurs, the buzzer sounds and the display shows a corresponding error message.

Take an appropriate remedy for the displayed error.

Warning messages

Message

Cause

Solution

The front cover or the maintenance

cover is opened.

Check the front cover and maintenance

covers.

If the same error message appears again

even after closing all the covers, contact

your local distributor to call for service.

A media has not been set.

Set media.

The battery life end of the internal

clock is detected.

Contact your local distributor to call for

service.

Time to replace the wiper in the

capping station with a new one has

come.

(The wiping count has reached the

specified value.)

Replace the wiper with a new one.

(

P.4-7)

The nozzle recovery cannot be

expected because the machine has

been left standing for a prolonged

period of time.

Perform test printing then check nozzle

clogging.

In the case of nozzle clogging observed,

perform cleaning. (

P.2-24)

In the case of significant nozzle clogging

observed, perform the operations of P.4-

10"Washing of Head nozzle".

A heater is disconnected.

(This example shows that pre-

heater is disconnected.)

Contact your local distributor to call for

service.

The thermistor of a heater is defec-

tive.

(This example shows that the

thermistor of pre-heater is defec-

tive.)

Ink for one supply path has been

nearly used up.

Replace the cartridge for the supply path

corresponding to the indicated color.

You can print without replacing the car-

tridge (until INK END is displayed).

However, the machine returns to local

mode every completion of printing one file.

Ink for one supply path has been

completely used up.

Replace the cartridge for the supply path

corresponding to the indicated color.

Ink cannot be supplied due to the

cartridge per one supply path.

Check the cartridge for the supply path

corresponding to the indicated color.

C l o s e a c o v e r .

* * NO ME D I A * *

! E X C H A NGE B A T T E R Y

< L OC A L . 1 >

[ # 0 1 ]

R e p l a c e a W I P E R < MN T >

< L OC A L . 1 >

[ # 0 1 ]

! D o T E S T D R AW

P R E

P R T

POS T

B R E A K

* * ° C

* * ° C

P R E

P R T

POS T

T H E RM

* * ° C

* * ° C

< L OC A L . 1 >

[ # 0 1 ]

N E A R E ND

MMC C - - - -

* R EMO T E . 1 *

[ # 0 1 ]

N E A R E ND

MMC C - - - -

< L OC A L . 1 >

[ # 0 1 ]

I N K E ND

- - - - Y Y K K

* R EMO T E . 1 *

[ # 0 1 ]

I N K E ND

- - - - Y Y K K

< L OC A L . 1 >

! C A R

[ # 0 1 ]

* R EMO T E . 1 *

! C A R

[ # 0 1 ]

Содержание JV33-130

Страница 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D201694 16 ...

Страница 7: ...vi ...

Страница 99: ...3 35 Machine settings 3 Convenient use Examples of Output ...

Страница 101: ...3 37 Machine settings 3 Convenient use 7 Press the key 8 Press the key several times to end ...

Страница 114: ...3 50 ...

Страница 147: ...Setting Routine operations 4 33 4 Routine Maintenance 8 Press the key several times to end ...

Страница 162: ...Replacing the cutter blade 4 48 4 Close the front cover 5 Press the key The machine returns to LOCAL mode ...

Страница 181: ...Warning labels 6 7 6 Appendix No Reorder Label 1 M901549 2 M903239 3 M903330 4 M903405 5 M904810 ...

Страница 185: ...6 11 Function Flowchart 6 Appendix To P 6 12 To P 6 18 To P 6 24 To P 6 25 To P 6 26 ...

Страница 189: ...6 15 Function Flowchart 6 Appendix OFF LEVEL 1 3 1 Wh i t e L a y P r t SE L OF F ...

Страница 201: ...D201694 16 31012012 ...

Страница 202: ...NH FW 5 3 MIMAKI ENGINEERING CO LTD 2012 ...