2-59

6.3 INSPECTION AND ADJUSTMENT

[1] Parts inspection

Subject area

Judgment criteria

Remedy

・

Housing

・

Block body

・

Scratch and blemish, stain or corrosion of spool sliding area

・

Scratch and blemish, stain or corrosion of the seal pocket of

spool insertion area

・

Scratch and blemish, stain or corrosion of the port seal in

contact with the O-ring

・

Scratch and blemish, stain or corrosion of the sealing area of

relief valve

・

Any other damage that may spoil normal functions

・

Replacement

・

Replacement

・

Replacement

・

Replacement

・

Replacement

・

Spool

・

Scar that catches a finger nail of the circumferential sliding

surface when touched

・

Blemishes on the sliding surface mating with an end seal

・

Spool action is not smooth.

・

Replacement

・

Replacement

・

Repair or replace

・

Load check valve

・

Imperfect sealing due to damage of valve or spring

・

When inserted in a block body and allowed to operate, it

should move smoothly without being caught.

・

Repair or replace

・

Normal

・

Spring and its periphery

・

Significant damage such as stain, corrosion, deformation or

breakage of spring, holder, and cover

・

Replacement

・

Spool sealing area

・

Outward oil leakage

・

Stain, corrosion or deformation of seal holder

・

Repair or replace

・

Repair or replace

・

Main relief valve

・

Port relief valve

・

Anti-cavitation valve

・

Stain or damage in appearance

・

Damage on the valve seat mating surface

・

Damage on the poppet mating surface

・

Fault in spring

・

O-ring, backup ring, and seals

・

Replacement

・

Replacement

・

Replacement

・

Replacement

・

Total replacement

is required in

principle.

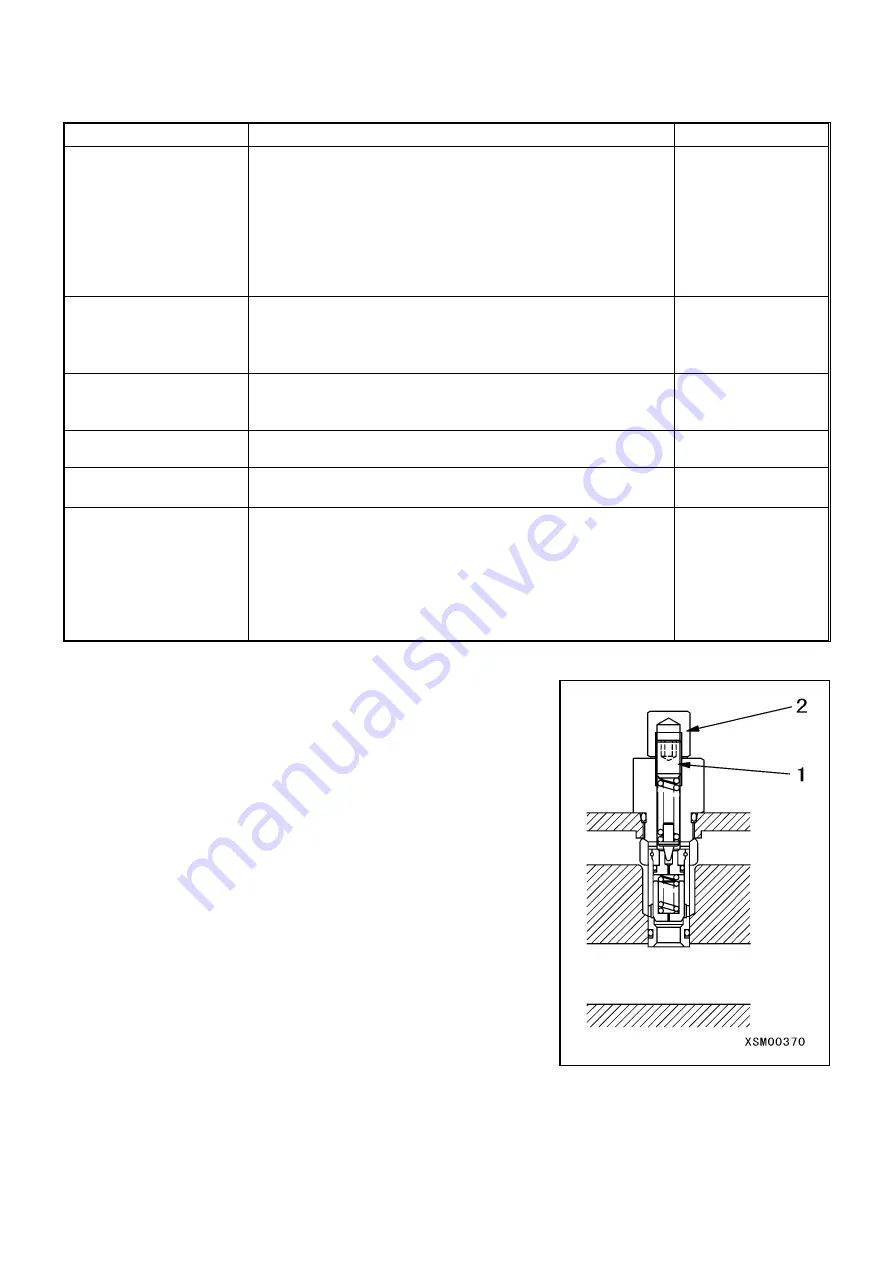

[2] Pressure adjustment of main relief valve

1. Attach a pressure gauge to the pressure detection port.

2. Run the pump at its rated revolution speed.

3. Allow the control valve spool to move to its full stroke and read the

pressure gauge value.

4. Loosen the lock nut (2) of main relief valve.

5. While watching the pressure gauge, turn set screw (1) to adjust the

pressure.

・

Clockwise direction (turning rightward): To raise the set

pressure.

・

Counterclockwise direction (turning leftward):

To lower the set pressure.

6. After completing the pressure adjustment, tighten the lock nut (2)

while preventing the set screw (1) from turning.

7. Run the pump again at its rated revolution speed to ensure that the

pressure is stabilized.

Содержание MK0003

Страница 2: ......

Страница 8: ...0 6...

Страница 12: ...1 4 2 DIMENSIONAL DRAWING OF OUTRIGGER WIDTH...

Страница 17: ...1 9 4 WORKING RADIUS LIFTING HEIGHT...

Страница 18: ...1 10 Working range diagram Outrigger extended to maximum Main boom 1 section...

Страница 19: ...1 11 Working range diagram Outrigger extended to maximum Main boom 2 sections...

Страница 20: ...1 12 Working range diagram Outrigger extended to maximum Main boom 2 5 sections...

Страница 21: ...1 13 Working range diagram Outrigger extended to maximum Main boom 3 sections...

Страница 22: ...1 14 Working range diagram Outrigger extended to minimum Main boom 1 section...

Страница 23: ...1 15 Working range diagram Outrigger extended to minimum Main boom 2 sections...

Страница 24: ...1 16 Working range diagram Outrigger extended to minimum Main boom 2 5 sections...

Страница 25: ...1 17 Working range diagram Outrigger extended to minimum Main boom 3 sections...

Страница 26: ...1 18 5 RATED TOTAL LOAD CHART...

Страница 32: ...2 4...

Страница 33: ...2 5 1 HYDRAULIC CIRCUIT DIAGRAM 200 1176600...

Страница 34: ...2 6...

Страница 35: ...2 7 2 HYDRAULIC PIPING DIAGRAM 2 1 CRANE ROTATING PART 200 1171800...

Страница 41: ...2 13 2 2 CONTROL LINE A...

Страница 43: ...2 15 2 3CONTROL LINE B Perform spiral winding on the entire perimeter of the hose of this part...

Страница 45: ...2 17 2 4 TRAVEL LINE...

Страница 47: ...2 19 2 5 OUTRIGGER LINE...

Страница 49: ...2 21 2 6 PT LINE 102 1152000 4...

Страница 69: ...2 41...

Страница 70: ...2 42...

Страница 71: ...2 43...

Страница 76: ...2 48 4 8 ENGINE ACCESSORIES 102 1149200...

Страница 90: ...2 62 7 2 INTERNAL STRUCTURE...

Страница 120: ...2 92 Part B Writing method for wire number Two places...

Страница 123: ...2 95 Figure 1 Index point Figure 2 Connection diagram...

Страница 166: ...2 138 15 4 APPEARANCE OF OUTRIGGER ON REAR LEFT SIDE 200 2167300...

Страница 173: ...2 145 17 ELECTRIC CIRCUIT DIAGRAM 200 1176500 01...

Страница 174: ...2 146 18 ELECTRIC SYSTEM 18 1 1 WIRE HARNESS OF MACHINE BODY 1 200 1172200 1...

Страница 176: ...2 148 18 1 2 WIRE HARNESS OF MACHINE BODY 2 200 1172200 2...

Страница 179: ...2 151 19 CONTROL ASSEMBLY 19 1 CONTROLLER 1 TTC60 Pin arrangement...

Страница 180: ...2 152 TTC60 I O...

Страница 181: ...2 153 2 TTC36X Pin arrangement...

Страница 182: ...2 154 TTC36X lower part I O...

Страница 209: ...2 181 19 2 5 LIST OF CONTROLLER INPUT MONITORING...

Страница 210: ...2 182 19 2 6 LIST OF CONTROLLER ANALOG INPUT OUTPUT MONITORING...

Страница 245: ...3 9 1 2 3 ANGLE METER 360 S200M3297000...

Страница 274: ...3 38...

Страница 293: ...4 19 8 SERVICE LOCATIONS...

Страница 294: ...4 20...

Страница 296: ...5 2 1 ELECTRICAL MOTOR UNIT ASSEMBLY Unit weight 180 kg...

Страница 299: ...5 5 1 1 POWER UNIT 1 Power unit cover 2 Electric motor 3 Coupling 4 Hydraulic pump Power supply box...

Страница 323: ...5 29 3 POWER SUPPLY BOX 1 Power supply box 2 Power supply box door 3 Door handle 4 Terminal block 5 Cable inserting hole...

Страница 324: ...5 30...

Страница 325: ...5 31 4 ELECTRICAL DIAGRAM S200M3122000 01...

Страница 326: ...5 32 S200M3122000 02...

Страница 336: ...6 8 1 3 2 INTERNAL STRUCTURE OF WINCH MOTOR...

Страница 345: ...6 17 4 WORKING RADIUS LIFTING HEIGHT OF ONE FALL WINCH...

Страница 348: ......