5-15

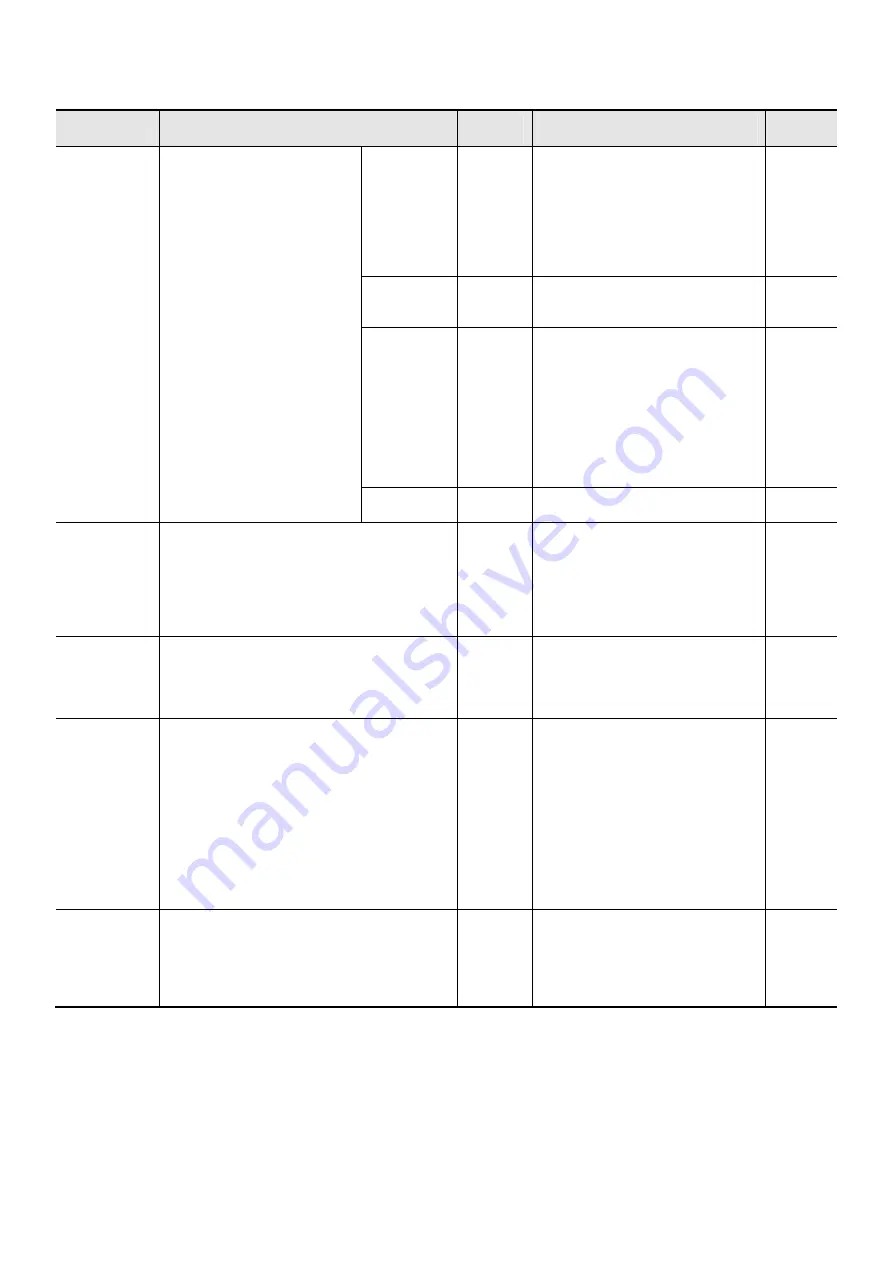

2.6 LIST OF ALARM CODES

Name

Content

Alarm

code

Check content and

countermeasures

Reference

Overcurrent

protection

If the motor is restrained or if it

is put under sudden

acceleration/deceleration,

large amount of current will

flow into the inverter, and may

cause damage. Therefore, the

protection circuit will activate at

approximately 200% of the

inverter rated output current,

and trips.

During

constant

speed

operation

E01.

Are there any sudden changes in

load?

• Decrease the amount of load

changes.

Are there any short-circuits?

• Check the output line.

Are there any ground faults?

• Check the output line and motor.

During

deceleration

E02.

Are there any sudden deceleration?

• Make the deceleration time

longer.

During

acceleration

E03.

Are there any sudden acceleration?

• Make the acceleration time

longer.

Are motor locks observed?

• Check the motor and wiring.

Is the torque boost high?

• Lower the torque boost.

• Is the setting and adjustments of

the motor correct when in PM

motor?

Other E04.

Is the DC control too high?

• Lower the damping force.

Overload

protection

*1

The output current of the inverter is being

monitored, and if the internal electric thermal

detects an overload of the motor, it will trip. If

the overload protection of the motor and

inverter is separated under the settings of the

motor electric thermal function selection (b910),

it will function as a motor overload protection.

E05.

Is there excessive load?

• Lower the load factor.

Is the thermal level (b012/b212)

correct?

• Adjust so that it is correct.

Overload

protection of

the limiting

resistor

Trips when the activity ratio of the regenerative

braking exceeds the activity ratio configured in

b090.

E06.

Are there any sudden deceleration?

• Make the deceleration time

longer.

Is the run cycle too short?

• Make the run cycle longer.

Overcurrent

protection

If the DC current between P/+2 and N/-

becomes too high, it may result in damage.

Therefore, the motor will trip if the DC current

between P/+2, N/- exceeds approximately DC

400V (200 V level)/800 V (400 V level) due to

the rising of regenerative energy or receiving

voltage.

E07.

Are there any sudden deceleration?

• Make the deceleration time

longer.

Are there any ground faults?

• Check the output line and motor.

Is the motor being rotated from the

load side?

• Reduce the regenerative power.

Is the receiving voltage rising?

• Lower the receiving voltage, limit

the power supply variation, use

AC reactor for input.

EEPROM

error

*2

Trips when faults in the internal EEPROM occur

due to abnormal rising of external noise or

temperature. (May result in CPU errors in some

cases.)

E08.

Is there any source of strong noise?

• Take measures for the noise.

Is the cooling efficiency dropping?

• Check the cooling fin for

clogging, and clean.

• Replace cooling fan.

*1: Reset operation will not be available until approximately 10 seconds elapses after the trip (after the protection function

activates).

*2: Reset operation with the RS port or the STOP/RESET key will not be available when errors occur. Turn the machine off once.

If an error occurs when powering on the next time, the memory is damaged, or the parameter has not been saved properly.

Initialize and reconfigure the parameter.

Содержание MK0003

Страница 2: ......

Страница 8: ...0 6...

Страница 12: ...1 4 2 DIMENSIONAL DRAWING OF OUTRIGGER WIDTH...

Страница 17: ...1 9 4 WORKING RADIUS LIFTING HEIGHT...

Страница 18: ...1 10 Working range diagram Outrigger extended to maximum Main boom 1 section...

Страница 19: ...1 11 Working range diagram Outrigger extended to maximum Main boom 2 sections...

Страница 20: ...1 12 Working range diagram Outrigger extended to maximum Main boom 2 5 sections...

Страница 21: ...1 13 Working range diagram Outrigger extended to maximum Main boom 3 sections...

Страница 22: ...1 14 Working range diagram Outrigger extended to minimum Main boom 1 section...

Страница 23: ...1 15 Working range diagram Outrigger extended to minimum Main boom 2 sections...

Страница 24: ...1 16 Working range diagram Outrigger extended to minimum Main boom 2 5 sections...

Страница 25: ...1 17 Working range diagram Outrigger extended to minimum Main boom 3 sections...

Страница 26: ...1 18 5 RATED TOTAL LOAD CHART...

Страница 32: ...2 4...

Страница 33: ...2 5 1 HYDRAULIC CIRCUIT DIAGRAM 200 1176600...

Страница 34: ...2 6...

Страница 35: ...2 7 2 HYDRAULIC PIPING DIAGRAM 2 1 CRANE ROTATING PART 200 1171800...

Страница 41: ...2 13 2 2 CONTROL LINE A...

Страница 43: ...2 15 2 3CONTROL LINE B Perform spiral winding on the entire perimeter of the hose of this part...

Страница 45: ...2 17 2 4 TRAVEL LINE...

Страница 47: ...2 19 2 5 OUTRIGGER LINE...

Страница 49: ...2 21 2 6 PT LINE 102 1152000 4...

Страница 69: ...2 41...

Страница 70: ...2 42...

Страница 71: ...2 43...

Страница 76: ...2 48 4 8 ENGINE ACCESSORIES 102 1149200...

Страница 90: ...2 62 7 2 INTERNAL STRUCTURE...

Страница 120: ...2 92 Part B Writing method for wire number Two places...

Страница 123: ...2 95 Figure 1 Index point Figure 2 Connection diagram...

Страница 166: ...2 138 15 4 APPEARANCE OF OUTRIGGER ON REAR LEFT SIDE 200 2167300...

Страница 173: ...2 145 17 ELECTRIC CIRCUIT DIAGRAM 200 1176500 01...

Страница 174: ...2 146 18 ELECTRIC SYSTEM 18 1 1 WIRE HARNESS OF MACHINE BODY 1 200 1172200 1...

Страница 176: ...2 148 18 1 2 WIRE HARNESS OF MACHINE BODY 2 200 1172200 2...

Страница 179: ...2 151 19 CONTROL ASSEMBLY 19 1 CONTROLLER 1 TTC60 Pin arrangement...

Страница 180: ...2 152 TTC60 I O...

Страница 181: ...2 153 2 TTC36X Pin arrangement...

Страница 182: ...2 154 TTC36X lower part I O...

Страница 209: ...2 181 19 2 5 LIST OF CONTROLLER INPUT MONITORING...

Страница 210: ...2 182 19 2 6 LIST OF CONTROLLER ANALOG INPUT OUTPUT MONITORING...

Страница 245: ...3 9 1 2 3 ANGLE METER 360 S200M3297000...

Страница 274: ...3 38...

Страница 293: ...4 19 8 SERVICE LOCATIONS...

Страница 294: ...4 20...

Страница 296: ...5 2 1 ELECTRICAL MOTOR UNIT ASSEMBLY Unit weight 180 kg...

Страница 299: ...5 5 1 1 POWER UNIT 1 Power unit cover 2 Electric motor 3 Coupling 4 Hydraulic pump Power supply box...

Страница 323: ...5 29 3 POWER SUPPLY BOX 1 Power supply box 2 Power supply box door 3 Door handle 4 Terminal block 5 Cable inserting hole...

Страница 324: ...5 30...

Страница 325: ...5 31 4 ELECTRICAL DIAGRAM S200M3122000 01...

Страница 326: ...5 32 S200M3122000 02...

Страница 336: ...6 8 1 3 2 INTERNAL STRUCTURE OF WINCH MOTOR...

Страница 345: ...6 17 4 WORKING RADIUS LIFTING HEIGHT OF ONE FALL WINCH...

Страница 348: ......