5-24

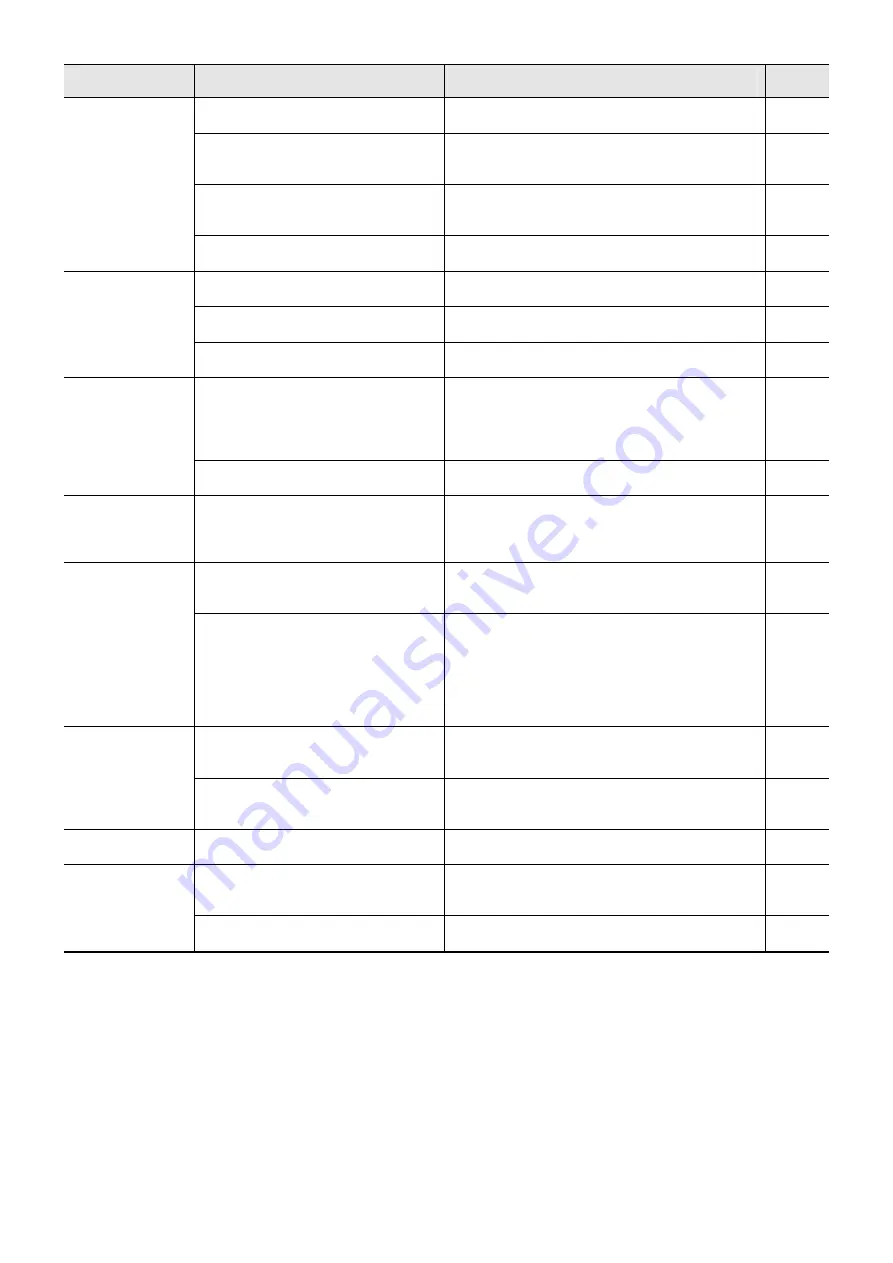

Symptom

Content of the likely cause

Countermeasures

Reference

Unable to run/set

from the optional

unit

(communication

unit).

The primary/secondary run command

selection (A002/A202) is incorrect.

Set the primary/secondary run command selection

(A002/A202) to “04: optional unit”.

The primary/secondary frequency

command selection (A001/A201) is

incorrect.

Set the primary/secondary frequency command

selection (A001/A201) to “04: optional unit”.

Incorrect address.

Check that the index/sub index (EtherCat) and

Class/Instance/Attribute (CompoNet/DeviceNet)

are correct.

Modbus mapping function is set.

Set the Modbus mapping function selection (P200)

to “00: standard Modbus address”.

Unable to connect

the CX-Drive.

CX-Drive version is incorrect.

Prepare Ver. 2.8 if connecting 3G3MX2 series V1

type.

The software number of the inverter is

inconsistent.

Match the CX-Drive to the software number of the

inverter to connect to.

The endian function of the Modbus

mapping function is set improperly.

Set Modbus mapping endian selection (P400) to

“00: big endian”.

Unable to set the

parameter from

CX-Drive.

The inverter is running.

Stop the inverter, and reset the settings after the

motor slows down and stops. If set to the mode

where changes are permitted while running (b031 =

10), some of the parameters can be changed while

running.

Modbus mapping function is set.

Set the Modbus mapping function selection (P200)

to “00: standard Modbus address”.

Overload

protection (E05)

occurs on brake

control.

Inverter is running in brake restrain

state.

Release the run command of the inverter in brake

restrain state. Overload protection may occur in DC

breaking.

Brake error (E36)

occurs on brake

control.

Brake control release current has not

been reached.

Either make the brake control release wait time

(b121) longer, or reduce the brake control release

current (b126).

Brake check signal is not being

inputted.

• Correct the wirings of the brake check signal

(44: BOK). If not in use, remove the brake check

signal from the multi function input setting.

• Correct the sequence so that the brake check

signal (44: BOK) is inputted after the brake

release.

• Replace the brake if it is damaged.

Load drops on

brake control.

Insufficient brake control release

current.

• Raise the brake control release current (b126).

• Set the control method (A044/A244) to “03:

sensor less vector control”.

The frequency to release/restrain the

brake is low.

Raise either the brake control release frequency

(b125), brake control restrain frequency (b127) or

the creep speed setting (P015).

PM motor rotates

on startup.

The motor magnetic pole position is

incorrect on startup.

Set the PM motor start method selection (H123) to

“01: default position estimation enabled”.

Overcurrent

protection (E03)

occurs when

starting with the

PM motor.

PM motor is out of step.

Raise the PM motor start current (H117).

Adjust according to the “PM motor mode

adjustment”.

Excessive load.

Reduce the load. Or make the acceleration time

longer.

Содержание MK0003

Страница 2: ......

Страница 8: ...0 6...

Страница 12: ...1 4 2 DIMENSIONAL DRAWING OF OUTRIGGER WIDTH...

Страница 17: ...1 9 4 WORKING RADIUS LIFTING HEIGHT...

Страница 18: ...1 10 Working range diagram Outrigger extended to maximum Main boom 1 section...

Страница 19: ...1 11 Working range diagram Outrigger extended to maximum Main boom 2 sections...

Страница 20: ...1 12 Working range diagram Outrigger extended to maximum Main boom 2 5 sections...

Страница 21: ...1 13 Working range diagram Outrigger extended to maximum Main boom 3 sections...

Страница 22: ...1 14 Working range diagram Outrigger extended to minimum Main boom 1 section...

Страница 23: ...1 15 Working range diagram Outrigger extended to minimum Main boom 2 sections...

Страница 24: ...1 16 Working range diagram Outrigger extended to minimum Main boom 2 5 sections...

Страница 25: ...1 17 Working range diagram Outrigger extended to minimum Main boom 3 sections...

Страница 26: ...1 18 5 RATED TOTAL LOAD CHART...

Страница 32: ...2 4...

Страница 33: ...2 5 1 HYDRAULIC CIRCUIT DIAGRAM 200 1176600...

Страница 34: ...2 6...

Страница 35: ...2 7 2 HYDRAULIC PIPING DIAGRAM 2 1 CRANE ROTATING PART 200 1171800...

Страница 41: ...2 13 2 2 CONTROL LINE A...

Страница 43: ...2 15 2 3CONTROL LINE B Perform spiral winding on the entire perimeter of the hose of this part...

Страница 45: ...2 17 2 4 TRAVEL LINE...

Страница 47: ...2 19 2 5 OUTRIGGER LINE...

Страница 49: ...2 21 2 6 PT LINE 102 1152000 4...

Страница 69: ...2 41...

Страница 70: ...2 42...

Страница 71: ...2 43...

Страница 76: ...2 48 4 8 ENGINE ACCESSORIES 102 1149200...

Страница 90: ...2 62 7 2 INTERNAL STRUCTURE...

Страница 120: ...2 92 Part B Writing method for wire number Two places...

Страница 123: ...2 95 Figure 1 Index point Figure 2 Connection diagram...

Страница 166: ...2 138 15 4 APPEARANCE OF OUTRIGGER ON REAR LEFT SIDE 200 2167300...

Страница 173: ...2 145 17 ELECTRIC CIRCUIT DIAGRAM 200 1176500 01...

Страница 174: ...2 146 18 ELECTRIC SYSTEM 18 1 1 WIRE HARNESS OF MACHINE BODY 1 200 1172200 1...

Страница 176: ...2 148 18 1 2 WIRE HARNESS OF MACHINE BODY 2 200 1172200 2...

Страница 179: ...2 151 19 CONTROL ASSEMBLY 19 1 CONTROLLER 1 TTC60 Pin arrangement...

Страница 180: ...2 152 TTC60 I O...

Страница 181: ...2 153 2 TTC36X Pin arrangement...

Страница 182: ...2 154 TTC36X lower part I O...

Страница 209: ...2 181 19 2 5 LIST OF CONTROLLER INPUT MONITORING...

Страница 210: ...2 182 19 2 6 LIST OF CONTROLLER ANALOG INPUT OUTPUT MONITORING...

Страница 245: ...3 9 1 2 3 ANGLE METER 360 S200M3297000...

Страница 274: ...3 38...

Страница 293: ...4 19 8 SERVICE LOCATIONS...

Страница 294: ...4 20...

Страница 296: ...5 2 1 ELECTRICAL MOTOR UNIT ASSEMBLY Unit weight 180 kg...

Страница 299: ...5 5 1 1 POWER UNIT 1 Power unit cover 2 Electric motor 3 Coupling 4 Hydraulic pump Power supply box...

Страница 323: ...5 29 3 POWER SUPPLY BOX 1 Power supply box 2 Power supply box door 3 Door handle 4 Terminal block 5 Cable inserting hole...

Страница 324: ...5 30...

Страница 325: ...5 31 4 ELECTRICAL DIAGRAM S200M3122000 01...

Страница 326: ...5 32 S200M3122000 02...

Страница 336: ...6 8 1 3 2 INTERNAL STRUCTURE OF WINCH MOTOR...

Страница 345: ...6 17 4 WORKING RADIUS LIFTING HEIGHT OF ONE FALL WINCH...

Страница 348: ......