LAGUNA

TOOLS

11

1.

There

are

two

water

tubes

that

come

out

of

the

caterpillar

track.

These

are

used

to

provide

cooling

for

the

liquid

‐

cooled

router

spindle.

Note:

Never

run

the

motor

without

the

cooling

being

connected

or

the

motor

could

be

damaged.

2.

Connect

one

water

tube

to

the

water

pump

and

place

the

other

in

the

water

container

for

the

return

water.

3.

It

is

not

important

which

pipe

is

used

as

the

return.

4.

Fit

the

90

degree

connector

to

the

pump.

5.

Connect

one

of

the

pipes

to

the

water

pump

by

pushing

into

the

90

degree

connector.

Lightly

pull

on

the

pipe

to

ensure

that

it

is

connected

correctly.

6.

Fill

a

container

about

¾

full

with

clean

water.

Note.

You

will

need

to

provide

a

coolant

tank

with

a

minimum

capacity

of

5

gallons.

If

the

shop

temperature

is

high,

the

tank

size

will

have

to

be

larger.

If

your

shop

is

likely

to

be

subject

to

freezing

temperatures,

antifreeze

must

be

added

to

the

cooling

water.

7.

Lower

the

water

pump

into

the

container

ensuring

that

it

is

the

correct

way

up

[water

inlet

lowest]

and

place

the

water

return

pipe

into

the

container.

8.

The

logical

position

for

the

water

container

is

just

behind

the

control

box

close

to

the

caterpillar

track.

Ensure

that

it

is

close

to

the

machine

as

you

do

not

want

to

accidentally

kick

the

container

and

spill

the

water.

9.

Once

the

assembly

is

complete

and

the

water

pump

electrical

connection

has

been

made,

plug

the

pump

into

the

machine

water

pump

socket

and

then

lift

the

water

return

pipe

up

and

check

that

the

water

is

flowing.

10.

Place

the

lid

onto

the

container

to

keep

dust

and

dirt

out

of

the

container.

Check

the

container

periodically

as

the

water

will

evaporate.

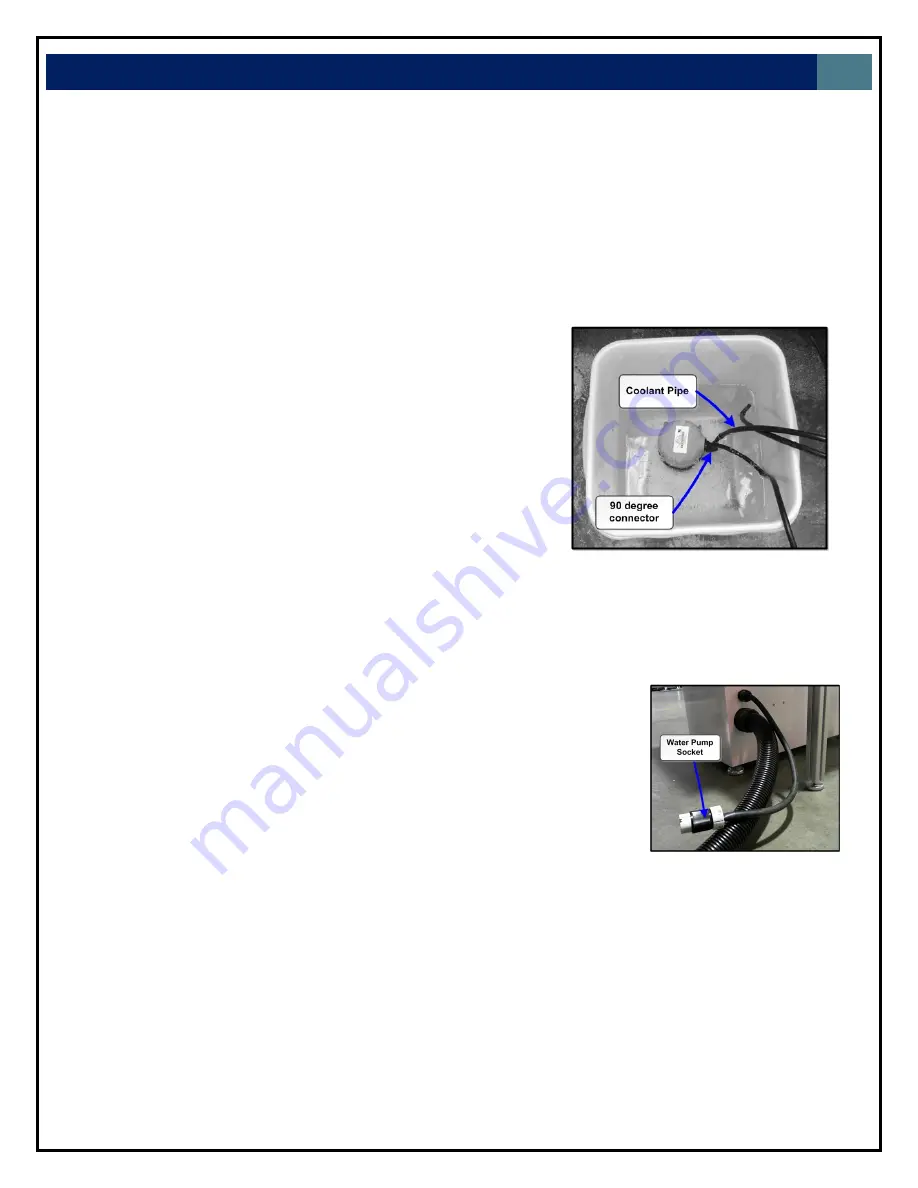

Figure

9.

Water

pump

in

coolant

reservoir

Figure

10.

Water

pump

power

supply

Содержание CNC Swift Series

Страница 54: ...LAGUNA TOOLS 54 SPECIFICATIONS...