Troubleshooting Basics

6-4

KVAL Operation/Service Manual

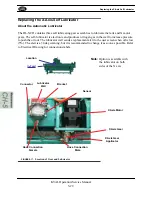

Analyze the Sub Systems

1.

Check the

Load

for mechanical issues

• Is the Load “bound up?

• Is there sufficient lubrication?

• Is it an alignment issue?

• Is anything damaged?

2.

Check the

Position Feed Back

.

• Does the

Position Feed Back

agree with the

Load

position?

In other words are the correct photo eyes, limit switches or ferrous sensors activated? Check the con-

troller inputs to insure the proper sensors are activated. If the controller is a PLC, an activated input is

lit. Some touch screens have inputs status also.

3.

Common Position Feedback failures:

•

Photo Eye:

Bad element or bad cable

•

Limit Switch:

Stuck, or failure

•

Wiring:

Broken, worn insulation

•

PLC:

Bad input port.

4.

Check

the

Positioning System

• Follow the circuit from the

Controller

output to the

Load

and check for component

failures.

Содержание Edge-SS

Страница 5: ...KVAL Edge SS Operation Service Manual ...

Страница 12: ...KVAL Edge SS Line Operation Service Manual ...

Страница 30: ...How to Download the Service Application 1 18 KVAL Operation Service Manual Page Intentionally Left Blank ...

Страница 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Страница 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Страница 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Страница 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Страница 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Страница 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Страница 173: ......

Страница 177: ......

Страница 178: ......

Страница 179: ......