SECTION 4 - BASE COMPONENTS

4-16

– JLG Lift –

3121222

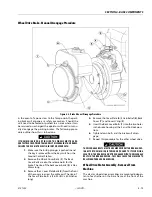

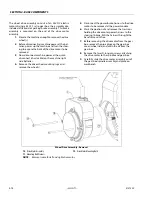

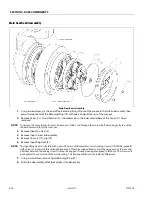

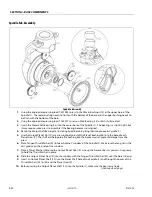

Drive Motor Inspection and Servicing

(Reference Figure 4-5. - Drive Motor Disassembly Illustra-

tion)

1.

Carefully blow out any accumulated carbon dust

and dirt from the end head and the frame and

field assembly using clean, oil free, compressed

air.

2.

Replace brushes (3) that are worn below their

usable length (.600 in.), show signs of uneven

wear or signs of overheating, such as discolored

brush shunts and brush springs. Brushes should

always be replaced in complete sets of four or

eight. Use identical replacement parts; do not

substitute brush grades as the brushes are

matched to the motor type and application to

provide the best service. Substituting brushes of

the wrong grade can cause premature commu-

tator failure and excessive brush wear.

3.

Make sure the brush box assembly (5) is tight on

the commutator end head. Replace brush box

assemblies in the commutator end head if they

are physically damaged or brush holders are

loose on the brush plate.

4.

Visually inspect the frame and field assembly (1)

for overheating or other signs of damage. Check

all wiring to insure that the insulation is in good

condition. Verify that pole screws are torqued to

250-300 in-lb [28.2-33.9 N-m]. Verify field resis-

tance using a suitable ohmmeter per the appro-

priate motor specification. Verify that the field is

electrically isolated from the frame using a

dielectric tester. Replace as necessary.

5.

Visually inspect the armature (2) assembly for

signs of overheating or physical damage. Visu-

ally inspect the seal surface of the shaft for

excessive wear. Check for grounded circuits

using a dielectric tester by applying voltage

between the commutator and the shaft. Visually

inspect the commutator for excessive wear and

overheating. Replace as necessary.

6.

Visually inspect the brake surfaces for excessive

wear. Remove any RTV Silicone sealant that may

be present on the friction disc, cover, or commu-

tator end head. Replace brake assembly (11) if

necessary.

7.

Visually inspect the wire harness (8) for frayed

insulation, loose terminals, or other damage.

Replace as necessary.

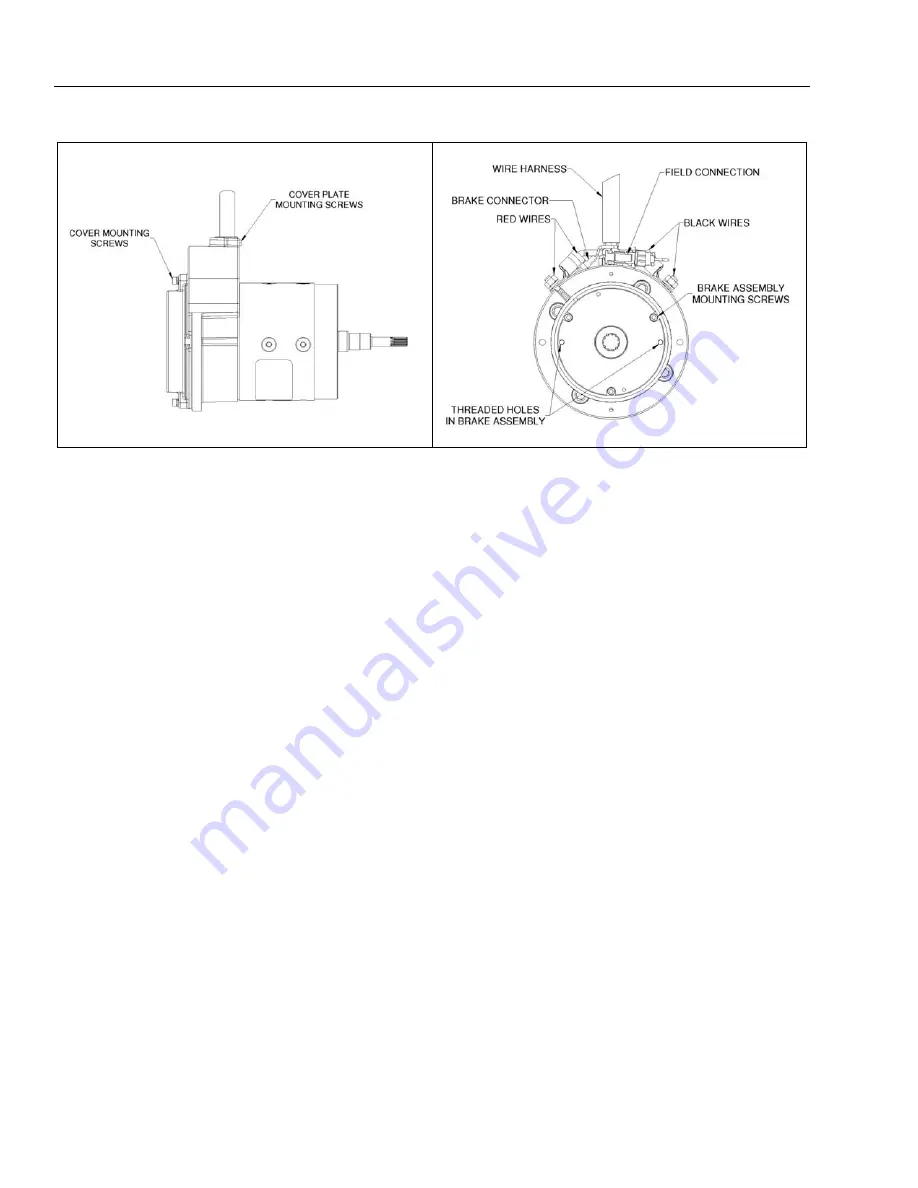

Figure 4-6. Drive Motor Side View

Figure 4-7. Drive Motor End View (Brake End)

Содержание 1230ES

Страница 1: ...AS NZS Service and Maintenance Manual Model s 1230ES P N 3121222 June 22 2017 ...

Страница 2: ...NOTES ...

Страница 24: ...SECTION 1 MACHINE SPECIFICATIONS 1 12 JLG Lift 3121222 NOTES ...

Страница 32: ...SECTION 2 GENERAL SERVICE INFORMATION 2 8 JLG Lift 3121222 NOTES ...

Страница 78: ...SECTION 4 BASE COMPONENTS 4 40 JLG Lift 3121222 NOTES ...

Страница 104: ...SECTION 5 CONTROL COMPONENTS 5 26 JLG Lift 3121222 NOTES ...

Страница 158: ...SECTION 8 DIAGNOSTIC TROUBLE CODES 8 22 JLG Lift 3121222 NOTES ...

Страница 169: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 11 Figure 9 5 Connector Installation ...

Страница 198: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 40 JLG Lift 3121222 ...

Страница 199: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 41 ...

Страница 200: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 42 JLG Lift 3121222 ...

Страница 202: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 44 JLG Lift 3121222 NOTES ...