Page 17

ENGLISH

Jandy

®

Pro Series, Hi-E2

®

and Hi-E2R Gas-Fired Heater

|

Installation & Operation Manual

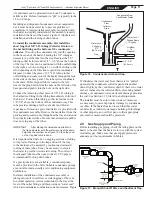

Figure 23. Step-down gas pressure regulator.

energizes a “hot surface” igniter.

5.

The igniter is allowed to reach ignition temperature,

at which it glows bright red-orange. This is visible

through the combustion chamber view port.

6.

The gas valve is opened and gas flows into the

combustion air. The gas/air mixture flows through

the burner into the combustion chamber. It is

ignited by the igniter.

7.

The ignition control electronically senses

successful ignition by “flame rectification”, and

the gas valve is allowed to stay on. The igniter is

de-energized.

8.

The heater operates for as long as the control

demands heat, subject to continued water flow

and satisfactory operation of the system.

9.

When the control stops calling for heat, the

ignition control shuts off the gas valve and the

flame goes out.

10. The ignition control continues to operate the

combustion blower for a “post-purge” period,

after which it is turned off.

The process is repeated upon the next call for heat. If ignition

is unsuccessful, or if the flame fails during normal operation,

the ignition shuts off the gas valve. It imposes a post purge

and two (2) more ignition cycles, and it shuts down the

system if ignition is not achieved in three (3) cycles.

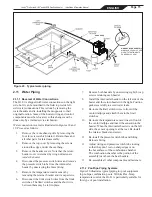

2.12.2 Start-up

Before operating the heater, pour water into the

condensate tray and verify that it drains properly. Confirm

that pool water is flowing normally through the pool

system and equipment. Start the heater in accordance

with the Operating Instructions section of this manual,

with particular attention to the lighting and shutdown

instructions and temperature control operation.

The heater may not start on the first try. Air in the gas line

or other start-up situations may cause it to recycle. It will

lock out if ignition is not achieved in three attempts. To

provide three (3) additional attempts, turn the pool/spa

selector switch off and then back on.

The maximum working pressure of this heater is 75

psig. Be sure to take into consideration the maximum

allowable pressure of the other components in the system

when installing a PRV. Any pressure relief valve installed

must comply with provisions of the standard described in

ANSI® Z21.22 for the United Sates or CSA 4.4 in Canada.

Some local codes may also require installation of a

temperature relief valve. Check with your local codes for

requirements in your area. The valve setting should be in

accordance with local codes. Zodiac

®

recommends that

the water delivered to the pool not exceed 104°F. All

temperature and/or pressure relief valves must be listed

by a Nationally Recognized Testing Lab (NRTL) such as

CSA, UL, or ETL.

2.11.5 Automatic Chlorinators (Chemical Feeders)

A high concentration of chlorine (and many similar

chemicals) in the pool heater can be very destructive.

Heater damage caused by chemical concentration is not

covered by the Warranty. See Table 7 for guidelines on

pool water chemistry.

IMPORTANT

Always install a corrosion resistant check

valve when any sanitation equipment, including erosion

feeders and salt chlorination systems are installed.

Wire an electric chlorinator so that it cannot operate unless the

filter pump is running. If the chlorinator has an independent

clock control, synchronize it with the filter clock.

If the chlorinator is equipped with its own pump, install it so

that it introduces the chlorine downstream from the heater,

and, if possible, below the level of the heater outlet fitting.

2.12 Start-up and Adjustment

2.12.1 Normal Operation

The Hi-E

2

pool heater operates automatically. It provides

heat in response to the selector switch and temperature

settings on the control panel on the front of the heater. The

heater has internal controls to sense adequate water flow

and to handle any abnormal condition.

Normal operation is as follows:

1.

The pool/spa system filter pump provides water

flow. A pressure-flow switch in the heater detects

water flow and enables the control to operate the

heater. (If the recommended fireman switch has

been provided, it must also enable operation.)

2.

If the selector switch is set to "Pool" or "Spa", and

if the water temperature is not warm enough, the

control signals the combustion system to start.

3.

The ignition control starts the combustion blower.

4.

When the venturi pressure switch detects

combustion air flow and when a suitable “pre-

purge” time has been allowed, the ignition control

Содержание HI-E2

Страница 2: ......

Страница 37: ...Page 37 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...

Страница 38: ...Page 38 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...

Страница 39: ...Page 39 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...